Description

Key Technical Specifications (For Spare Parts Verification)

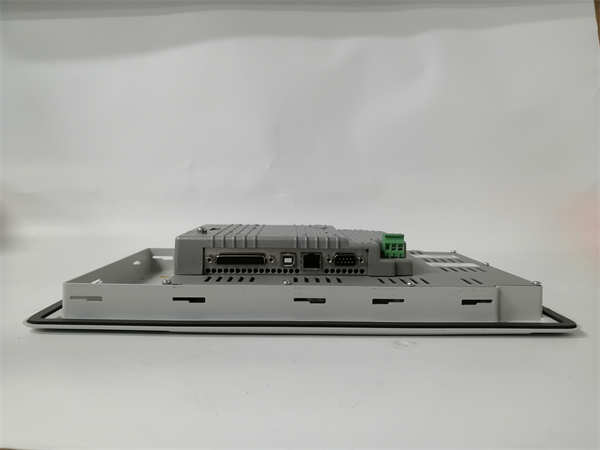

- Product Model: PP846

- ABB Order Code: 3BSE042238R1

- Manufacturer: ABB

- System Family: AC 800M Automation Platform (S800 I/O System)

- Output Voltage: 24 VDC ±3%

- Maximum Output Current: 10 A continuous

- Input Voltage Range: 85–264 VAC, 47–63 Hz (universal input)

- Redundancy Support: Yes – supports parallel operation with second PP846 via redundancy cable (ABB part 3BSE013208R1)

- Diagnostic Features: LED indicators for OK, Overload, and Fuse status; dry contact alarm output

- Mounting: Standard slot in AC 800M/S800 power/base chassis (e.g., TB840A, TB850A)

- Safety Certifications: CE, UL, CSA, IEC 60950-1

System Role and Downtime Impact

The ABB PP846 is the primary power source for AC 800M control racks in industrial process applications such as power generation, water treatment, and mining. It supplies regulated 24 VDC to all modules in the chassis—including CPUs, communication cards, and I/O modules—via the backplane. In redundant configurations, two PP846 units share the load, allowing one to fail without system interruption.

However, if a single PP846 fails in a non-redundant rack—or if both fail in a redundant setup—the entire chassis loses power. This results in immediate loss of control logic execution and I/O communication, typically triggering a plant-wide process trip or safe state. Because the PP846 is often deployed in remote I/O cabinets or motor control centers, its failure may disable dozens of field devices simultaneously, leading to extended downtime during troubleshooting and replacement.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the PP846 exhibits predictable age-related failure patterns:

- Electrolytic capacitor degradation: The input and output filtering capacitors dry out over time (especially in high-temperature environments), causing output ripple, voltage sag under load, or complete shutdown due to overvoltage/undervoltage protection trips.

- Fan failure (in early revisions): Some PP846 variants included a small internal cooling fan; bearing wear leads to overheating and thermal shutdown.

- Output diode or MOSFET failure: In redundant setups, failed isolation diodes can prevent proper load sharing or cause backfeeding, leading to unexpected behavior during failover.

A key vulnerability is the reliance on internal fuses that are not user-replaceable—meaning any short-circuit event typically renders the entire unit unusable. Preventive maintenance should include:

- Annual thermographic inspection to detect abnormal heating

- Monitoring of the “PSU Alarm” dry contact in the DCS for early fault indication

- Ensuring adequate ventilation around the rack (minimum 100 mm clearance)

- Verifying redundancy cable integrity in dual-PSU systems

ABB PP846 3BSE042238R1

Lifecycle Status and Migration Strategy

ABB has officially discontinued the PP846 and replaced it with the PP851 (3BSE069270R1) and PP852 (3BSE069271R1) series, which offer higher efficiency, improved diagnostics, and better thermal performance. The PP846 is no longer listed in current ABB price lists or e-commerce platforms.

Continued use poses operational risk: spare units are only available from third-party brokers, with inconsistent quality and no OEM warranty. Some recovered units have been refurbished without proper capacitor rework, leading to premature field failures.

Short-term mitigation includes:

- Securing tested spares with documented load and thermal validation

- Avoiding operation near maximum ambient temperature (keep <45°C)

- Implementing rack-level power monitoring to detect early degradation

For long-term reliability, ABB recommends upgrading to the PP851/PP852 platform. These newer supplies are mechanically and electrically compatible with existing AC 800M chassis and require no backplane changes. However, users must:

- Update firmware in connected CPUs to support new PSU diagnostics (if used)

- Replace redundancy cables with updated versions (3BSE069272R1)

- Revalidate power budget if adding new I/O

Given its critical role in system availability, proactive replacement of aging PP846 units—even before failure—is a prudent strategy to avoid unplanned outages in legacy but still-operational AC 800M installations.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: