Description

Key Technical Specifications

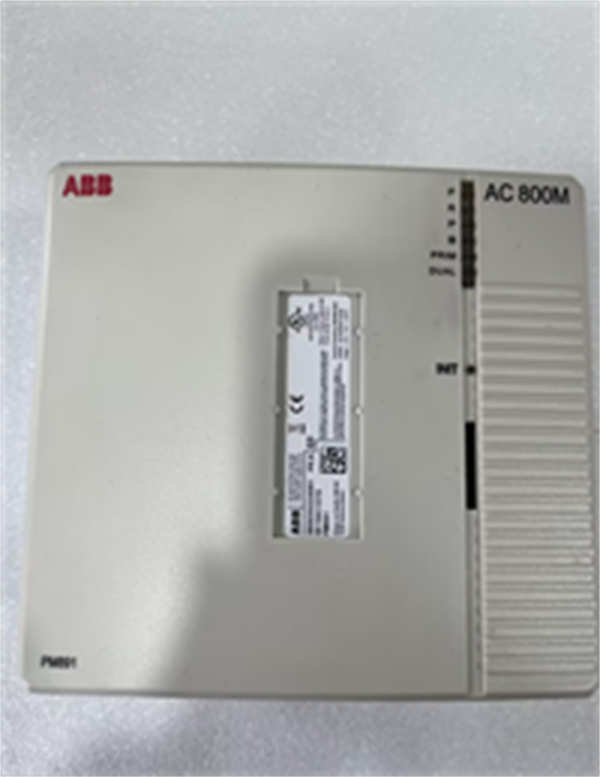

- Product Model: PM891

- Manufacturer: ABB

- System Platform: AC 800M (part of ABB’s System 800xA architecture)

- Processor Type: 32-bit RISC, real-time operating system

- Program Memory: 8 MB (non-volatile)

- Data Memory: 4 MB

- Scan Cycle Time: As low as 1 ms for typical logic

- Communication Interfaces: Dual Ethernet (for control network and engineering), optional serial port

- Supported Fieldbus: PROFIBUS DP, PROFINET IO, Modbus TCP, Foundation Fieldbus (via I/O modules)

- Redundancy: Full controller and communication redundancy supported

- Operating Temperature: 0°C to +60°C (derated above 50°C)

Core Performance and Selection Advantages

The ABB PM891 delivers a balanced combination of processing power, reliability, and lifecycle value for industrial automation projects. Compared to earlier AC 800M CPUs like the PM86x series, it offers significantly faster program execution—critical for time-sensitive interlocks and motion coordination in hybrid applications. Its 8 MB program memory accommodates complex logic without requiring external storage, reducing system footprint and failure points.

Key functional strengths include built-in support for controller redundancy, which ensures continuous operation during hardware faults—a vital feature in continuous-process industries. The module also integrates a web server for basic diagnostics and status monitoring, enabling quick troubleshooting without full engineering access. From a total cost of ownership (TCO) perspective, the PM891 reduces engineering effort through tight integration with ABB’s Automation Builder and System 800xA, allowing unified configuration of control logic, HMI, and asset management. This eliminates the need for protocol converters or third-party gateways when connecting to higher-level systems, lowering both hardware costs and long-term maintenance complexity.

ABB PM891 3BSE053240R1

System Integration and Expandability

The PM891 is programmed and configured using ABB Automation Builder, part of the broader System 800xA ecosystem. This platform supports IEC 61131-3 languages and enables seamless data flow between controllers, operator stations, and enterprise systems. Its engineering environment streamlines version control, simulation, and online change capabilities—accelerating commissioning and reducing downtime during modifications.

In terms of connectivity, the PM891 natively supports PROFINET and PROFIBUS for field device integration, while its dual Ethernet ports facilitate separation of control traffic and engineering access. It also provides built-in OPC UA server functionality, enabling direct, secure data exchange with MES, SCADA, and cloud platforms without additional middleware. For IIoT initiatives, this simplifies deployment of analytics and remote monitoring solutions.

The module scales effectively within the AC 800M architecture: it can manage up to 64 local or remote I/O modules via optical or copper links, supporting thousands of I/O points. Redundant configurations are straightforward to implement using a synchronization link between two PM891 units. Additionally, it interoperates with ABB’s wide range of I/O families—including high-density, intrinsically safe, and motion modules—making it adaptable to diverse application requirements from batch processing to turbine control.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: