Description

Technical Specifications (For Spare Parts Verification)

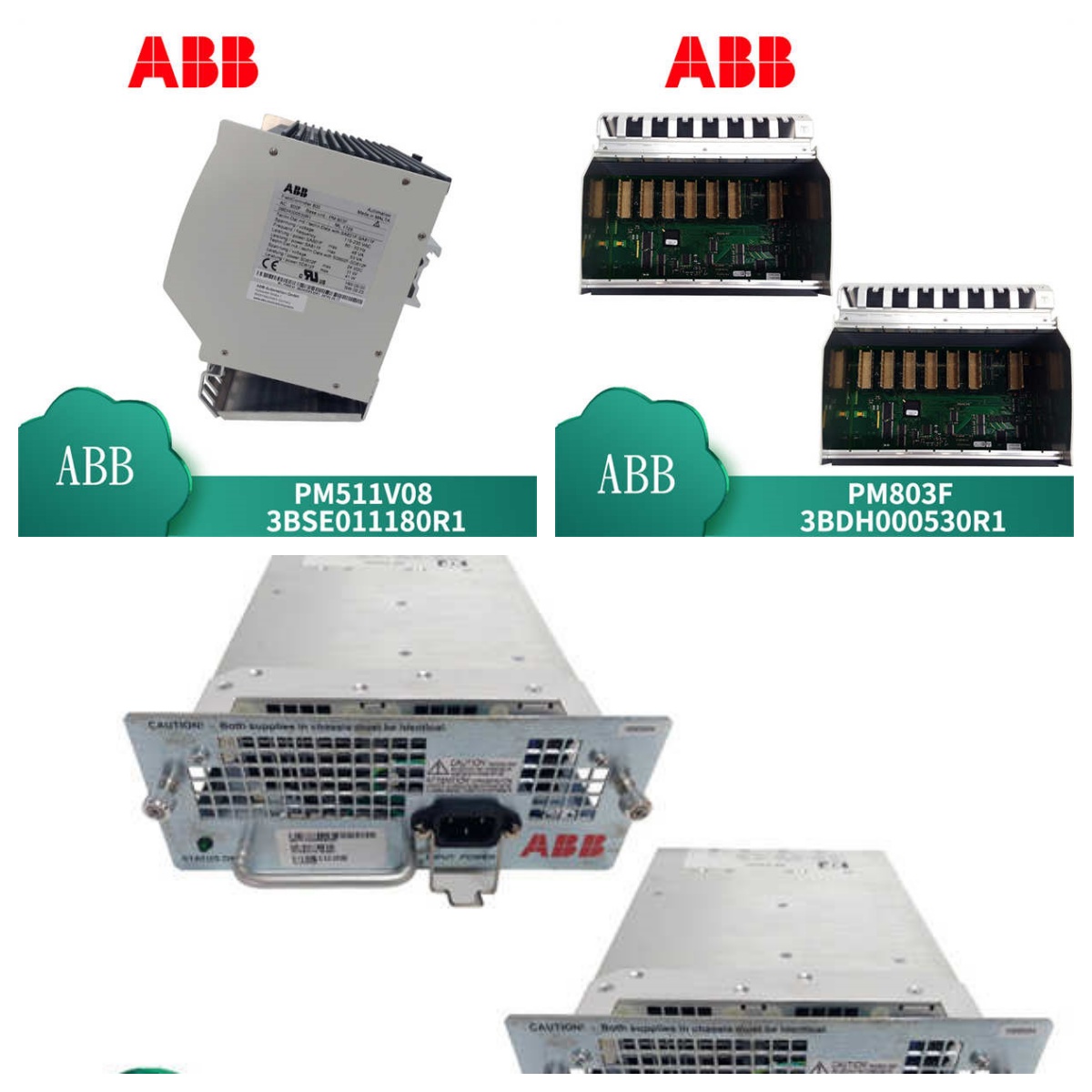

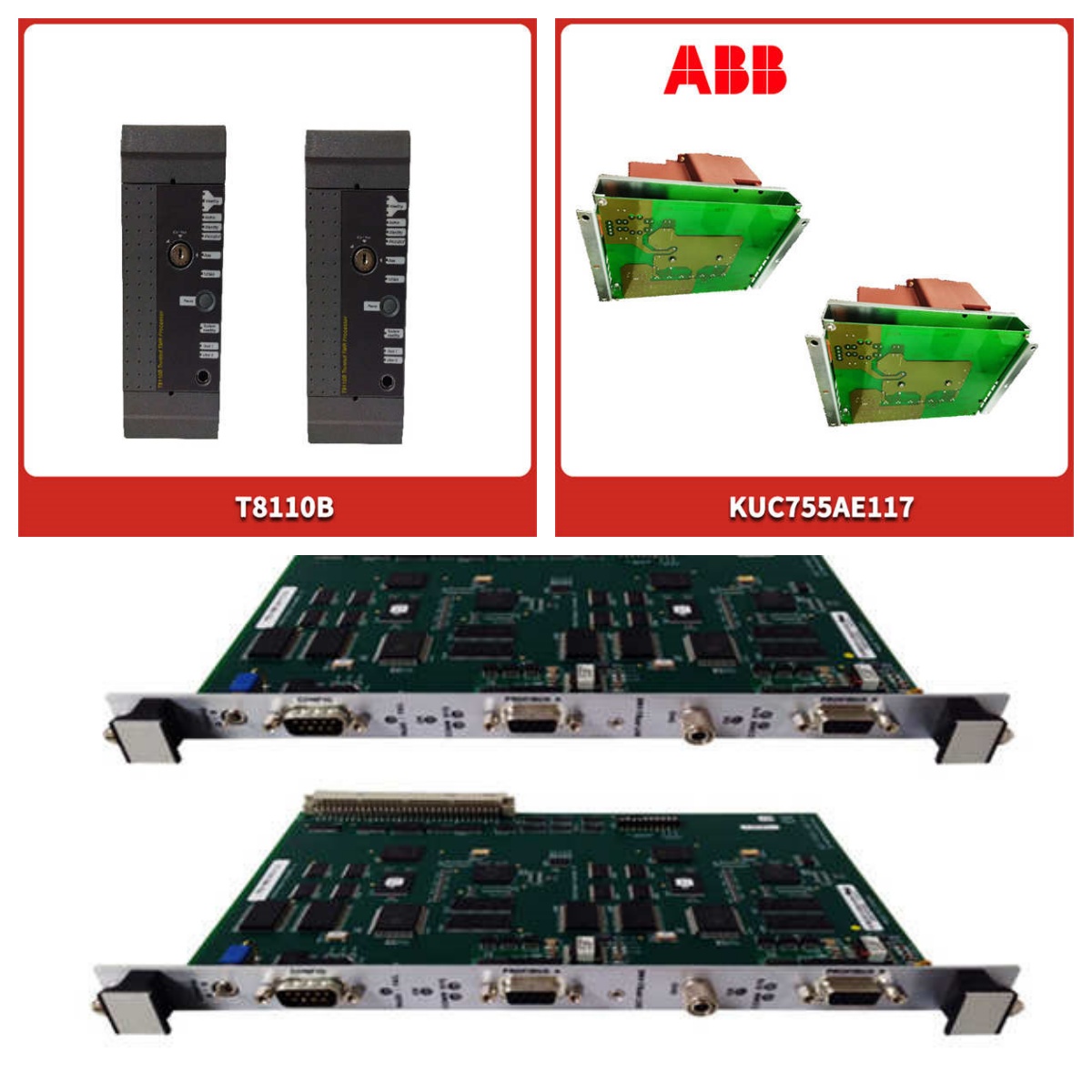

- Product Model: PM866AK01

- Manufacturer: ABB

- System Family: AC 800M Controller (part of ABB’s System 800xA architecture)

- Processor Type: PowerPC-based embedded CPU

- Memory: Integrated application memory (non-volatile), supports battery-backed RAM (requires periodic replacement)

- Redundancy Support: Yes – operates in primary/standby pair with automatic switchover

- Communication Interfaces: Dual PROFIBUS DP ports, CEX bus for I/O modules, Ethernet for engineering access

- Firmware Dependency: Must match exact firmware version used in the target system (e.g., v2.1, v3.0)

- Physical Indicators: LEDs for RUN, STOP, I/O COMM, REDUNDANCY STATUS, and BATTERY FAULT

- Mounting: DIN-rail mounted in AC 800M controller rail with dedicated power and backplane connectors

- Power Supply: +24 VDC via backplane; sensitive to voltage sags and ripple

System Role and Downtime Impact

The PM866AK01 is the computational heart of the AC 800M controller. In redundant configurations—common in continuous-process industries like power generation or chemical manufacturing—it runs the entire control application, manages I/O scanning, executes safety interlocks, and communicates with the 800xA operator system. If the active CPU fails due to hardware fault or memory corruption, the standby unit should take over seamlessly. However, if both units are degraded or a single-unit system fails, the result is an immediate and total loss of automated control. This typically triggers emergency shutdown sequences or forces manual operation, which may not be feasible in high-risk environments. Unplanned downtime can cost tens of thousands of dollars per hour in lost production or regulatory penalties.

Reliability Analysis and Common Failure Modes

Despite its robust design, the PM866AK01 is now well beyond its intended service life in many installations. Units still operating are often 10–15 years old, making component aging a dominant failure driver.

Common failure modes include:

- Battery-backed RAM failure: The onboard lithium battery depletes over time (typical life: 5–8 years). Once dead, configuration data may be lost during power cycles, causing boot failures.

- Flash memory wear-out: Repeated firmware updates or power interruptions can corrupt the internal file system, leading to “Application Load Error” or boot loops.

- Backplane connector corrosion: Oxidation on edge connectors causes intermittent communication with I/O modules, manifesting as sporadic I/O dropouts.

- Capacitor degradation: Onboard electrolytic capacitors dry out, causing unstable internal voltages and erratic behavior under thermal stress.

Design weaknesses include reliance on non-replaceable internal batteries and limited self-diagnostics for memory health. The module is also vulnerable to ESD during handling and ground potential differences in poorly maintained cabinets.

Preventive maintenance recommendations:

- Replace the backup battery every 5 years, even if no fault is indicated.

- Monitor “BATTERY LOW” LED status during routine rounds.

- Keep firmware stable—avoid unnecessary updates on aging hardware.

- Clean backplane contacts annually with contact-safe cleaner and inspect for bent pins.

Lifecycle Status and Migration Strategy

ABB has formally obsoleted the PM866AK01 and ended repair services. Continuing to rely on this module exposes facilities to escalating risks: dwindling spare availability, rising costs (prices have increased 300–500% since discontinuation), and zero official technical support.

Short-term risk mitigation includes:

- Acquiring and functionally testing at least one matched spare (same revision and firmware level).

- Implementing strict change control to avoid unnecessary power cycles or firmware changes.

- Documenting full system backups (including hardware configuration) for rapid recovery.

For long-term sustainability, ABB’s official migration path is to the AC 800M PM866AK02 (if still available) or, more realistically, to the next-generation AC 800M High Performance Controller (PM865/PM866 with newer firmware) within the 800xA v6+ environment. However, true future-proofing requires planning a full transition to ABB Ability™ System 800xA with AC 500 or AC 800M Gen 2 platforms, which offer enhanced cybersecurity, virtualization support, and extended lifecycle commitments.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: