Description

Key Technical Specifications (For Spare Parts Verification)

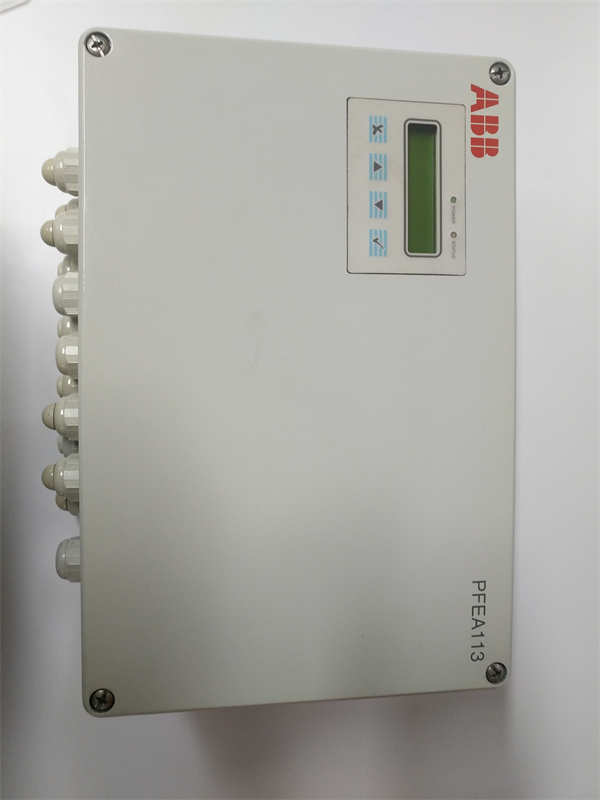

- Product Model: PFEA113-65

- Manufacturer: ABB

- System Family: AC 800M (part of ABB’s 800xA distributed control system)

- Input Channels: 16 differential channels

- Input Signal Range: 0–20 mA or 4–20 mA (software-configurable per channel)

- Resolution: 16 bits

- Accuracy: ±0.1% of full scale at 25°C

- Isolation: Channel-to-channel and channel-to-backplane isolation (500 V RMS)

- Update Rate: Approx. 5 ms per channel (full scan ~80 ms)

- Backplane Interface: Connects via S800 I/O bus to AC 800M CPU (e.g., PM86x series)

- Diagnostic Features: Per-channel open-circuit detection, overrange indication

- Physical Form: Standard S800 module (requires S800 baseplate and terminal blocks, e.g., TB820/TB840)

System Role and Downtime Impact

The PFEA113-65 is a foundational analog input module in ABB AC 800M-based control systems widely deployed in power plants, oil & gas facilities, and chemical processing since the early 2000s. It typically resides in remote I/O cabinets, converting field transmitter signals (e.g., pressure, temperature, flow) into digital data for the central controller. A single failed module can disrupt up to 16 independent control loops—potentially triggering alarms, forcing manual operation, or initiating safety shutdowns in critical processes such as boiler feedwater control or reactor temperature regulation. Because these systems often operate continuously, unplanned downtime due to I/O failure carries significant operational and financial consequences.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, the PFEA113-65 exhibits age-related vulnerabilities common to early-generation S800 modules. The most prevalent failure mode is input channel drift or complete loss, often caused by degradation of precision resistor networks or op-amps due to thermal cycling over decades of service. A second frequent issue is communication loss with the backplane, typically resulting from corrosion on the DIN connector pins or solder joint fatigue on the PCB. Additionally, power supply transients—especially in facilities with poor grounding—can damage the isolated input front-end, leading to short circuits or erratic readings.

Design limitations include lack of hot-swap capability and dependence on external terminal blocks that may suffer from oxidation or loose wiring over time. For maintenance teams, recommended preventive actions include:

- Performing annual calibration checks using a precision current source

- Inspecting and cleaning backplane connectors during scheduled outages

- Verifying terminal block torque and replacing oxidized blocks proactively

- Maintaining at least one fully tested spare module with matching firmware revision

ABB PFEA113-65 3BSE050092R65

Lifecycle Status and Migration Strategy

ABB has formally discontinued the PFEA113-65 (3BSE050092R65) as part of its legacy S800 I/O portfolio. No new units are manufactured, and official support is limited to existing service contracts. Continued reliance on this module introduces risk of extended downtime due to parts scarcity and rising costs in the secondary market.

As an interim measure, operators may source and functionally test surplus modules, implement redundant I/O strategies where feasible, or use external signal conditioners to isolate critical loops. However, the long-term solution is migration within the ABB ecosystem. The direct functional successor is the PFEA113-70 (3BSE050092R70), which offers identical channel count and signal compatibility but with improved diagnostics and extended lifecycle support. Migration requires only hardware replacement—no logic reprogramming—as it maintains backward compatibility with existing AC 800M CPUs and configuration databases in Control Builder M. For sites planning broader modernization, upgrading to the AC 800M High Availability platform or ABB Ability™ System 800xA with next-gen I/O provides enhanced cybersecurity, cloud connectivity, and lifecycle sustainability.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: