Description

Technical Specifications (For Spare Parts Verification)

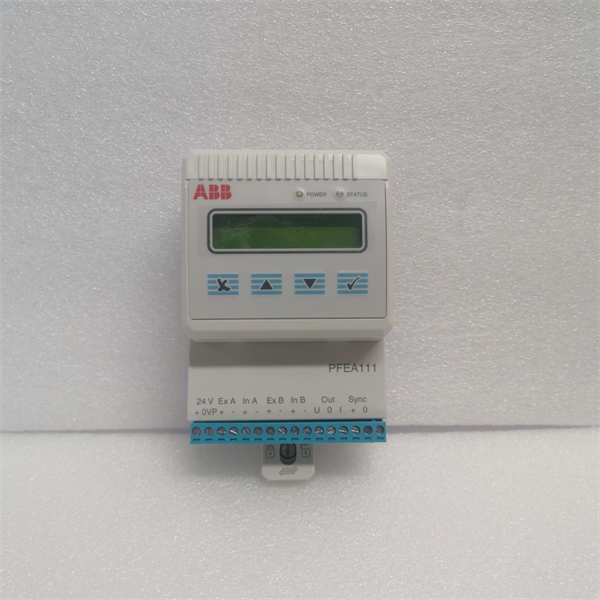

- Product Model: PFEA111-20

- Manufacturer: ABB

- System Compatibility: ABB AC 800M controller (used in System 800xA DCS)

- Module Type: Digital I/O (configurable per channel as input or output)

- Number of Channels: 16

- Electrical Isolation: Galvanic isolation between field and backplane (500 Vrms)

- Input Voltage Range: 24 VDC nominal (18–30 VDC acceptable)

- Output Capability: Sourcing type, max 0.5 A per channel

- Diagnostic Features: Per-channel LED indicators, module-level fault reporting via Profibus/Modulebus

- Mounting: Plug-in to standard AC 800M I/O baseplate (e.g., TB511, TB521)

- Certification: CE, UL 61010-1, IEC 61326-1

System Role and Downtime Impact

The PFEA111-20 is typically deployed in critical control or safety-related applications within ABB System 800xA installations—such as boiler protection in power plants, emergency shutdown logic in refineries, or conveyor interlocks in mining operations. It resides in a remote I/O station connected to an AC 800M CPU via Modulebus or Profibus. While the system may tolerate a single module failure through redundancy or bypass strategies, loss of 16 discrete signals simultaneously can compromise safety integrity or force a controlled shutdown. In continuous-process environments, unplanned downtime due to I/O module failure can result in production losses exceeding $500,000 per hour, along with potential regulatory reporting obligations if safety functions are impaired.

Reliability Analysis and Common Failure Modes

Many PFEA111-20 modules have operated reliably for 15+ years due to ABB’s robust industrial design. However, aging introduces predictable vulnerabilities. The most frequent failure mode is failure of optocouplers or output transistors due to repeated switching stress or voltage surges from field wiring. Secondary issues include corrosion on terminal blocks (in high-humidity environments) and cold solder joints on the PCB caused by thermal cycling over decades of operation. A notable design limitation is the lack of hot-swap capability—replacement requires powering down the I/O station, increasing maintenance window complexity.

Recommended preventive actions for maintenance teams:

- Conduct annual infrared thermography scans to detect abnormal heating on terminals or PCB

- Verify signal integrity using loop calibration tools during scheduled outages

- Inspect field wiring for signs of insulation degradation or ground faults that could stress the module

- Maintain at least one tested spare per unique configuration (input vs. output setup) in inventory

ABB PFEA111-20 3BSE050090R20

Lifecycle Status and Migration Strategy

ABB has officially discontinued the PFEA111 series. No new units are being manufactured, and factory repair services are no longer available. Continued reliance on this module carries escalating risks: scarcity of verified spares, rising costs (often 2–4x historical pricing), and diminishing technical support from ABB.

As an interim measure, facilities may source professionally refurbished units that undergo full functional retest—including channel-by-channel I/O validation and burn-in—to ensure reliability. However, this is not a long-term solution.

ABB’s recommended migration path is to upgrade to the PFEA113 series (e.g., PFEA113-20), which offers backward-compatible form factor and similar I/O density but with improved diagnostics, higher MTBF, and ongoing support. The transition requires:

- Reconfiguration of I/O assignments in Control Builder M

- Possible replacement of baseplates if older TB5xx versions lack compatibility

- Recertification of safety loops if used in SIL-rated applications

Organizations should perform a formal obsolescence risk review to decide between strategic sparing, board-level repair partnerships, or a phased migration to PFEA113—factoring in system criticality, regulatory requirements, and total cost of ownership over the asset’s remaining life.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: