Description

Technical Specifications (For Spare Part Verification)

- Product Model: NDCU-33CX

- Manufacturer: ABB

- Ordering Code: 3AUA0000052751

- Compatible Drive Series: ACS800 (specifically frame sizes R4–R8, typically 160–500 kW range)

- Core Functions: Hosts drive CPU, manages motor control algorithms, handles I/O signals, and supports fieldbus communication

- Onboard I/O: 6 digital inputs, 2 digital outputs, 2 analog inputs (±10 V / 0–20 mA), 1 analog output

- Communication Options: Supports optional fieldbus modules (e.g., RPBA-01 for PROFIBUS, NRPX for DeviceNet) via rear connector

- Firmware Dependency: Requires specific DriveWindow or DriveComposer software version (typically v2.x); settings not forward-compatible with ACS880

- Power Supply: Powered via backplane from drive’s auxiliary supply (24 VDC nominal)

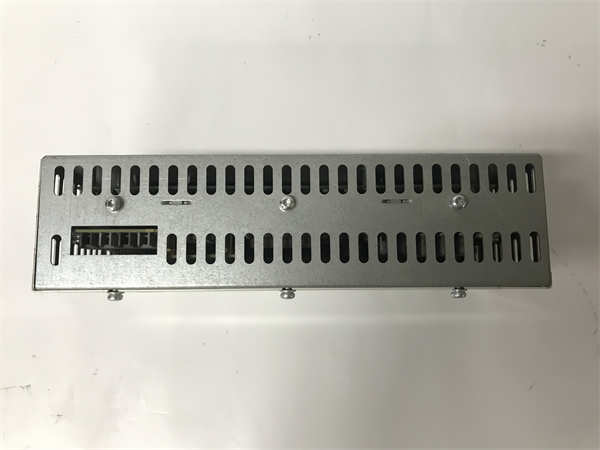

- Physical Form: Plug-in module installed vertically in ACS800 control compartment, secured with latch mechanism

- Diagnostic Features: LED indicators for RUN, ERROR, and fieldbus status; fault logging accessible via PC tool

System Role and Downtime Impact

The ABB NDCU-33CX is the central intelligence of the ACS800 drive, responsible for executing scalar or DTC (Direct Torque Control) motor algorithms, monitoring thermal and electrical conditions, and interfacing with higher-level control systems. It is commonly deployed in critical applications such as pumps, fans, and compressors in water treatment plants, HVAC systems, and industrial process lines. Because the NDCU integrates both control logic and safety-related protection (e.g., overcurrent, overload, phase loss), its failure immediately disables the drive output, halting motor operation. In continuous-process facilities—such as refineries or district heating networks—this can trigger cascading shutdowns. Furthermore, since the NDCU stores application-specific parameters, replacing it without a verified backup often requires on-site re-commissioning, extending downtime significantly.

Reliability Analysis and Common Failure Modes

Despite ABB’s robust industrial design, NDCU-33CX units in service beyond 10–15 years show characteristic aging issues. The most prevalent failure stems from electrolytic capacitors on the internal DC/DC converter circuit, which degrade due to thermal stress from nearby power electronics. This leads to unstable 5 V or 3.3 V rails, causing intermittent resets, corrupted parameter storage, or complete boot failure. Another frequent issue is corrosion or oxidation on the edge connector fingers, resulting from humidity ingress in non-climate-controlled environments—manifesting as communication dropouts or erratic I/O behavior.

A key vulnerability is the reliance on battery-backed SRAM (in some firmware revisions) to retain settings during power loss. When the onboard coin-cell battery depletes (typically after 8–12 years), parameters are lost on next power cycle, requiring full reconfiguration. Additionally, electrostatic discharge during handling or poor grounding can damage the sensitive FPGA or communication transceivers.

Recommended preventive measures include:

- Inspecting the NDCU annually for bulging capacitors or white residue (electrolyte leakage)

- Cleaning edge connectors with contact enhancer during routine maintenance

- Backing up drive parameters using DriveComposer while the unit is operational

- Replacing units proactively if battery voltage falls below 2.8 V (measurable via test points on PCB)

ABB NDCU-33CX 3AUA0000052751

Lifecycle Status and Migration Strategy

ABB has discontinued the NDCU-33CX as part of the broader phase-out of the ACS800 platform, with official support now focused on the ACS880 series. No direct replacement exists—the ACS880 uses an entirely different control architecture (DrivePM module) and is not mechanically or electrically compatible. Continuing to operate ACS800 drives with NDCU-33CX carries escalating risk: spare availability is constrained to used or refurbished inventory, firmware mismatches are common, and ABB no longer provides repair services or technical diagnostics for this generation.

As a short-term measure, facilities can:

- Secure tested, firmware-matched spares with verified parameter backups

- Implement drive redundancy (e.g., dual-drive setups with load sharing) where feasible

- Use external PLC-based monitoring to detect early signs of drive instability

For long-term sustainability, migration to the ACS880 is the recommended path. This involves:

- Replacing the entire power and control section (not just the NDCU)

- Rewriting application logic in the new Drive Composer Pro environment

- Updating electrical schematics and panel layouts

- Retraining maintenance personnel on the new HMI and diagnostic tools

While capital-intensive, this transition eliminates obsolescence exposure, improves energy efficiency, and enables integration with modern asset management and IIoT platforms via embedded Ethernet and OPC UA support. A staged rollout—starting with least critical drives—can mitigate operational risk during the transition.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: