Description

Key Technical Specifications (For Spare Part Verification)

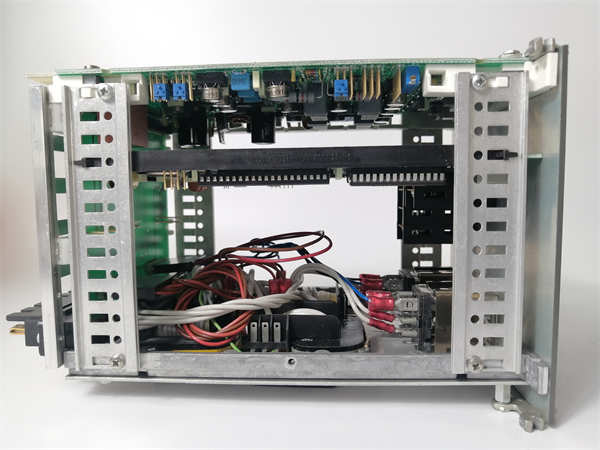

- Product Model: MC91

- Manufacturer: ABB

- System Family: AC 110 / AC 400 (predecessor to AC 800M)

- Processor Type: Proprietary 16/32-bit real-time CPU

- Memory: Battery-backed RAM for program and data retention (typically 512 KB–2 MB, variant-dependent)

- Communication Interfaces: Dual serial ports (RS-232/485), proprietary backplane bus for I/O

- Supported Protocols: MODBUS RTU, ABB proprietary fieldbus (e.g., COMLI)

- Redundancy: Optional hot standby with dual MC91 units (requires synchronization module)

- Power Supply: +5 VDC and ±12 VDC from system backplane

- Mounting: Slide-in module for standardized ABB control rack

- Diagnostic Indicators: Power, RUN, ERROR LEDs; limited fault codes via front panel

System Role and Downtime Impact

The MC91 serves as the central brain of ABB’s legacy AC 110 and AC 400 distributed control systems, widely deployed in power generation, pulp & paper, and heavy industry from the 1980s through early 2000s. It executes all regulatory and sequential control logic, manages I/O scanning, and coordinates communication with operator stations and field devices. In non-redundant configurations—which are common in older installations—failure of the MC91 results in immediate and total loss of automated control, forcing manual operation or complete process shutdown. Even in redundant setups, a failed primary unit increases stress on the backup and eliminates fault tolerance, often triggering plant derating or regulatory reporting requirements.

Reliability Analysis and Common Failure Modes

Despite robust initial design, the MC91 is increasingly vulnerable due to component aging. The most prevalent failure modes include battery-backed RAM corruption (especially if lithium batteries were not replaced every 5–7 years), leading to program loss or erratic behavior; degradation of onboard electrolytic capacitors causing power instability or boot failures; and corrosion or fretting on backplane connectors, resulting in intermittent communication with I/O modules. Additionally, the module’s reliance on obsolete surface-mount components makes board-level repair difficult without specialized expertise.

A key weakness is the lack of modern self-diagnostics—most faults manifest only as system halts or unexplained logic errors, requiring extensive troubleshooting. The absence of Ethernet or standardized protocols also complicates remote monitoring. Preventive maintenance should focus on: (1) proactive replacement of onboard backup batteries; (2) annual inspection of backplane contacts for oxidation or mechanical wear; (3) verifying stable backplane power rails under load; and (4) maintaining offline backups of application code and configuration files.

ABB MC91 HESG440588R4

Lifecycle Status and Migration Strategy

ABB discontinued the AC 110/400 platform over a decade ago, and the MC91 is no longer supported. Official documentation, firmware updates, and repair services are unavailable. Spare parts exist only in dwindling surplus inventories, often without functional testing or traceability—posing significant operational risk.

Temporary measures include stockpiling tested spares, implementing rigorous preventive maintenance, or engaging niche third-party vendors for reconditioning. However, these are unsustainable long-term.

ABB’s recommended migration path is transition to the AC 800M platform (e.g., PM86x or PM891 controllers) within the System 800xA architecture. This requires re-engineering I/O wiring, converting control logic from Composer/ProControl to Automation Builder, and re-commissioning the entire system. While capital-intensive, migration delivers enhanced cybersecurity, OPC UA connectivity, remote diagnostics, and at least 15+ years of future support. For facilities unable to fund full replacement, hybrid approaches—such as wrapping the legacy system with a modern gateway for supervisory monitoring—can provide interim risk mitigation. Early planning, including functional gap analysis and pilot validation, is essential to ensure safe and compliant transition.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: