Description

Key Technical Specifications (For Spare Parts Verification)

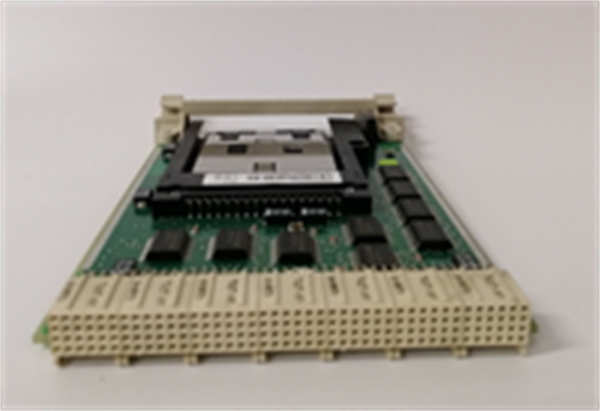

- Product Model: MB510

- Order Number: 3BSE002540R1

- Manufacturer: ABB

- System Compatibility: Advant Controller 410 and 450 (AC 400 family)

- Module Type: Main bus unit (backplane interface)

- Function: Distributes +5 V, ±12 V, and +24 V power rails; routes data between CPU, I/O, and communication modules

- Physical Form: Full-height plug-in card, occupies dedicated slot in AC 400 chassis

- Connectors: Gold-plated edge connector compatible with AC 400 backplane

- Indicators: Power OK and system status LEDs

- Redundancy Support: Non-redundant (standard configuration); redundant systems require dual MB510 in separate racks

- Mounting: Vertical insertion into designated slot (typically Slot 1) of AC 400 rack

System Role and Downtime Impact

The MB510 is not a field device—it is the foundational infrastructure of the Advant Controller 410/450 rack. Every I/O module, CPU, and communication card depends on it for both power and data synchronization. In operational plants still running AC 400 systems—such as hydroelectric turbines or chemical batch reactors—a failed MB510 typically causes an immediate and total loss of control over the associated process segment. Unlike peripheral I/O failures, which may be isolated, an MB510 fault collapses the entire rack’s functionality. Recovery requires physical replacement, and because these racks often lack hot-swap capability, the process must be fully shut down. Given the scarcity of verified spares, mean time to repair (MTTR) can exceed 72 hours, resulting in significant production loss and potential safety implications if emergency systems are affected.

Reliability Analysis and Common Failure Modes

Despite its robust design, the MB510 is vulnerable to age-related degradation. The primary failure mode is power regulator failure, particularly in the +5 VDC circuit that supplies logic to all modules. This is often preceded by capacitor bulging or leakage due to thermal stress over decades of operation.

A secondary but critical issue is corrosion or fretting at the edge connector, caused by repeated thermal expansion/contraction cycles. This leads to intermittent voltage drops or signal noise, manifesting as random module dropouts or CPU resets—symptoms that are difficult to diagnose without a known-good spare for swap testing.

The board also lacks modern protection features: it offers no overcurrent limiting on individual rails, making it susceptible to cascading failures if a downstream I/O module shorts. Additionally, the absence of conformal coating in many production batches leaves traces exposed to humidity-induced dendritic growth in tropical or coastal environments.

Recommended maintenance includes: annual infrared thermography of the rack to detect hot spots, visual inspection for capacitor deformation or PCB discoloration, cleaning the edge connector with contact enhancer during planned outages, and verifying all power rail voltages under full load. Facilities should maintain at least one fully tested MB510 spare in climate-controlled storage, ideally powered periodically to re-form capacitors.

MB510 3BSE002540R1 ABB

Lifecycle Status and Migration Strategy

ABB ceased all support for the Advant Master / AC 400 platform years ago. No new MB510 units are manufactured, and original test fixtures are no longer available. Continued reliance on this hardware exposes facilities to escalating risk: spares are finite, failure predictability is low, and integration with modern cybersecurity or asset management systems is impossible.

As a temporary measure, operators may source and functionally validate surplus units using a known-good AC 400 test rack. Some third-party specialists offer board-level repair, though long-term reliability cannot be guaranteed.

The definitive solution is migration to ABB’s current platform: the AC 800M controller within the System 800xA architecture. This requires full re-engineering—new I/O cabinets, updated application logic (conversion from Master Programming Language to IEC 61131-3 in Control Builder M), and integration with modern HMIs. While capital-intensive, this path restores access to lifecycle support, remote diagnostics, and compliance with current functional safety and cybersecurity standards. For sites unable to fund full replacement, ABB and certified partners offer “wrap-and-extend” strategies using protocol gateways to feed AC 400 data into supervisory layers, buying time for phased migration planning.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: