Description

Key Technical Specifications (For Spare Part Verification)

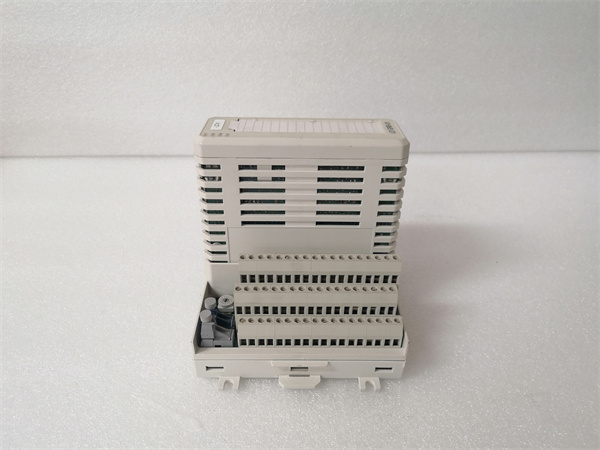

- Product Model: LDGRB-01

- ABB Order Code: 3BSE013177R1

- Manufacturer: ABB

- System Family: AC 800M Controller (used in System 800xA)

- Module Type: Combined digital input and output (configurable per channel)

- Channels: 8 channels, each individually configurable as DI or DO

- Input Type: 24 V DC, sink/source (depending on terminal base)

- Output Type: 24 V DC, short-circuit protected, max 0.5 A per channel

- Electrical Isolation: Channel-to-channel and field-to-backplane isolation

- Terminal Base Required: TB820 or TB821 (must match configuration)

- Diagnostic Coverage: Per-channel LED indication, fault reporting to controller

- Mounting: Plugs into AC 800M I/O rail with mechanical keying

System Role and Downtime Impact

The LDGRB-01 is typically deployed in auxiliary or balance-of-plant control panels within larger 800xA installations—such as boiler feedwater systems, conveyor networks, or cooling circuits—where mixed digital signals are needed in a compact footprint. Each channel can be independently configured during engineering, allowing flexible use without changing hardware.

Because it handles discrete signals that often serve as permissives or feedback for automated sequences, a failed LDGRB-01 can halt local process segments. For example, loss of a “pump running” feedback input or inability to energize a “damper open” output may prevent startup of a critical subsystem. While not always tied to a Safety Instrumented Function (SIF), its failure can trigger cascading process interruptions, especially in plants where redundancy was not implemented at the I/O level due to cost constraints.

In continuous-operation facilities (e.g., cement kilns, district heating plants), unplanned loss of this module—without a verified spare—can lead to forced derating or shutdown until replacement is sourced and validated, resulting in significant production loss.

Reliability Analysis and Common Failure Modes

The LDGRB-01 is generally robust but vulnerable to environmental and electrical stressors common in industrial settings. Its hybrid DI/DO design introduces complexity that can accelerate wear under suboptimal conditions.

Common failure modes include:

- Output driver burnout: Caused by sustained overcurrent (e.g., shorted field wiring) or inductive kickback from unshielded solenoid loads without flyback diodes.

- Input optocoupler degradation: Exposure to voltage transients or ground loops can damage the isolation barrier, leading to false “on” states or complete channel dropout.

- Backplane connector fatigue: Repeated thermal cycling causes micro-cracks in solder joints near the DIN rail connector, manifesting as intermittent communication faults.

- Configuration mismatch: Using an incorrect terminal base (e.g., TB820 vs. TB821) or miswiring can stress internal circuitry, though the module includes basic protection.

A key design limitation is the lack of hot-swap capability—replacement requires powering down the I/O rail segment, increasing downtime during repair. Additionally, diagnostic LEDs are visible only when the front cover is removed, complicating rapid field troubleshooting.

Preventive maintenance recommendations:

- Verify field wiring integrity annually, especially for inductive loads; ensure flyback protection is in place.

- Monitor channel status via 800xA diagnostics for early signs of drift or intermittent faults.

- Store spares in ESD-safe, climate-controlled environments to prevent component aging.

- Confirm terminal base compatibility before installation—mismatched bases can cause improper current limiting.

LDGRB-01 3BSE013177R1 ABB

Lifecycle Status and Migration Strategy

ABB officially discontinued the LDGRB-01 as part of its shift toward the Next Generation I/O architecture (based on CI854/CI860 communication modules and TU/TB85x terminal units). No direct “drop-in” replacement exists, as the new I/O system uses different physical form factors, communication protocols, and engineering tools.

Continued use carries escalating risks:

- Diminishing availability of tested, functional units

- Inability to obtain ABB technical support for hardware-specific issues

- Increasing difficulty in integrating with modern cybersecurity or remote access requirements

For sites unable to execute full migration immediately, recommended interim actions include:

- Securing a minimum of two fully tested spares with documented performance reports

- Implementing board-level repair agreements with specialized third-party service providers

- Segregating critical LDGRB-01 usage to non-SIL applications where possible

The long-term migration path involves upgrading to AC 800M High Availability CPUs with CI854A communication modules and TU85x/TB85x I/O terminals. This requires:

- Re-engineering of I/O allocation and signal routing

- Replacement of all terminal bases and wiring adapters

- Re-compilation of control applications in Control Builder M (compatible with newer firmware)

- Re-validation of control logic and HMI graphics

Organizations should conduct a formal obsolescence audit to identify all LDGRB-01 instances, assess criticality, and align replacement planning with plant turnaround schedules to minimize disruption. Delaying action increases exposure to unplanned outages driven by component failure rather than strategic upgrade.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: