Description

Technical Specifications (For Spare Parts Verification)

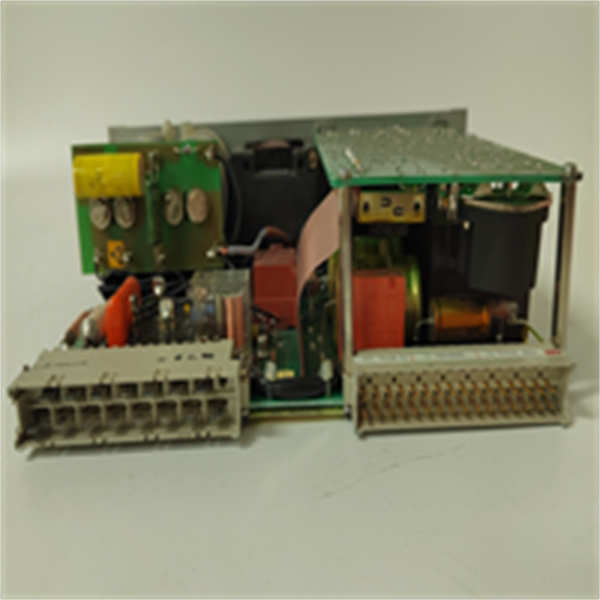

- Product Model: KX8974c V24 HIEE320606R1

- Manufacturer: ABB

- System Family: AC 800M (part of ABB Ability™ System 800xA)

- Module Type: Central Processing Unit (CPU), redundant-capable

- Firmware Compatibility: Requires specific firmware version aligned with 800xA engineering station (typically PG2/PG3 era)

- Memory Configuration: Onboard application memory (non-volatile), battery-backed RAM for runtime data

- Communication Interfaces: Dual optical PROFIBUS DP for I/O synchronization; Ethernet for engineering and HMI

- Redundancy Support: Hot-standby redundant pair operation with state synchronization

- Power Consumption: Approx. 5–8 W (dependent on load and I/O scan rate)

- Physical Form Factor: Standard DIN-rail mountable module for PM86x/PM89x rail system

System Role and Downtime Impact

The ABB KX8974c V24 HIEE320606R1 functions as the primary logic engine in AC 800M-based control systems, commonly deployed in power generation, oil & gas, and heavy industrial facilities. It executes all control logic, manages I/O communication, and coordinates with operator stations and other controllers. In a redundant configuration, it operates in sync with a backup unit to ensure continuity. If this module fails—especially in a non-redundant setup—the entire control station loses its ability to process logic, leading to immediate process interruption. Even in redundant setups, repeated failures or lack of a functional spare can force an unscheduled outage during switchover validation or repair.

Reliability Analysis and Common Failure Modes

Despite its robust design, the KX8974c V24 is now operating well beyond its intended service life in many installations. The most prevalent failure mechanisms stem from component aging:

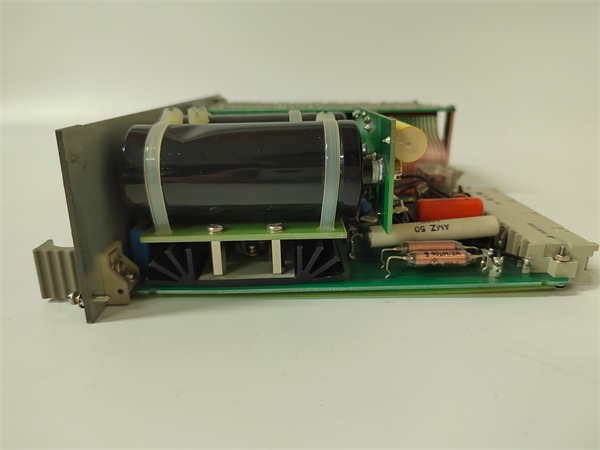

- Capacitor Degradation: Electrolytic capacitors on the power regulation circuit dry out over time, causing voltage instability, spontaneous reboots, or failure to power up.

- Battery-Backed RAM Issues: The onboard lithium battery (typically CR2032 or similar) depletes after 8–12 years, risking loss of runtime variables or configuration during power cycles.

- Optical Port Degradation: The PROFIBUS optical interfaces are sensitive to dust, misalignment, and LED aging, leading to intermittent I/O communication faults that are difficult to diagnose.

- Firmware Corruption: Rare but possible, especially after unclean shutdowns or voltage sags, resulting in boot loops or “invalid program” errors.

Preventive maintenance should focus on:

- Replacing the backup battery every 5–7 years, even if the system appears functional.

- Inspecting optical connectors for dust or physical damage during routine outages.

- Monitoring CPU temperature and ensuring adequate cabinet ventilation to slow capacitor aging.

- Maintaining at least one tested, matched spare in storage with identical firmware.

ABB KX8974c V24 HIEE320606R1

Lifecycle Status and Migration Strategy

ABB officially discontinued the KX8974c series as part of the broader AC 800M legacy phase-out. While the newer PM866A/PM865 CPUs remain active, the KX8974c (V24 revision) is no longer supported with new units or official repairs. Continued use carries significant risk: spare availability is limited to secondary markets, authenticity cannot be guaranteed, and ABB no longer provides firmware updates or diagnostic support.

In the short term, facilities may:

- Secure tested, matched spares from certified surplus channels.

- Engage specialized third-party services for board-level repair or reconditioning.

- Implement rigorous monitoring to detect early signs of degradation.

For long-term sustainability, ABB’s recommended migration path is to upgrade to the AC 800M PM866A or PM865 controller platform within the 800xA v6+ environment. This requires:

- Re-compilation of existing control logic in Control Builder M (newer version).

- Potential I/O re-mapping if using legacy I/O modules not supported in newer firmware.

- Engineering effort for testing and commissioning, but offers extended lifecycle, cybersecurity enhancements, and native OPC UA support.

Delaying migration increases operational vulnerability. A structured transition plan—not just a parts hunt—is the only reliable path forward.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: