Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: KUC711AE101

- Manufacturer: ABB

- System Family: AC 800M (part of System 800xA architecture)

- Processor Type: 32-bit RISC CPU

- Program Memory: 4 MB non-volatile flash

- Data Memory: 2 MB RAM (battery-backed)

- Communication Interfaces: Dual Ethernet ports (for control network and service access), optional serial port

- Supported Fieldbus: PROFIBUS DP, Modbus RTU/TCP, Foundation Fieldbus (via I/O modules)

- Redundancy: Not supported (non-redundant CPU variant)

- Power Consumption: Approx. 5 W

- Mounting: DIN rail or rack-mounted with compatible baseplate

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The KUC711AE101 is a foundational controller in mid-scale ABB AC 800M installations, commonly used in water/wastewater, small power units, and industrial process skids. It runs all application logic, scans local and remote I/O, and enables online diagnostics and programming via Automation Builder. As a non-redundant CPU, its failure immediately halts all automated functions under its control—potentially stopping pumps, valves, or safety interlocks. In unattended or remote facilities, this can lead to extended downtime, environmental incidents, or safety hazards before intervention occurs. Even in systems with manual backup, restoration may take hours due to dependency on specialized engineering tools for reconfiguration.

Reliability Analysis and Common Failure Modes

While designed for industrial use, the KUC711AE101 is now susceptible to age-related failures. The most common issues include battery-backed RAM corruption (if the onboard lithium battery was not replaced every 5–7 years), leading to data loss or boot failures; degradation of internal DC/DC converters causing intermittent resets; and Ethernet PHY chip failure due to thermal stress or ESD events. Additionally, repeated firmware updates or power cycling without proper shutdown can corrupt the flash file system, rendering the module unresponsive.

A notable limitation is the lack of hardware redundancy—any CPU fault requires physical replacement and potential re-downloading of the application program. Diagnostic capabilities are basic, often requiring connection to Automation Builder for detailed error logs. Preventive maintenance should include: (1) scheduled replacement of the backup battery; (2) periodic verification of application backups; (3) inspection of ventilation and ambient temperature around the module; and (4) functional testing during planned outages to validate boot sequence and I/O communication.

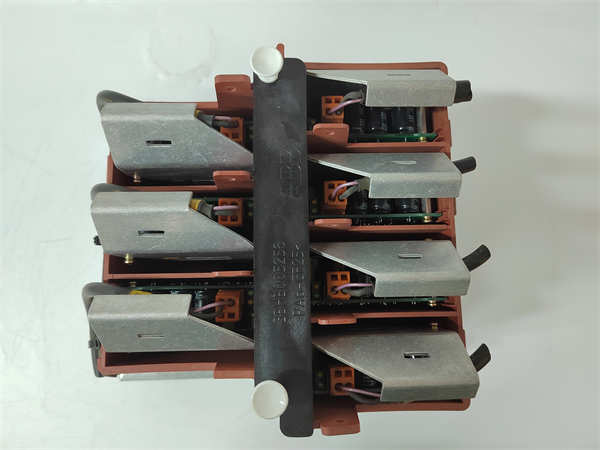

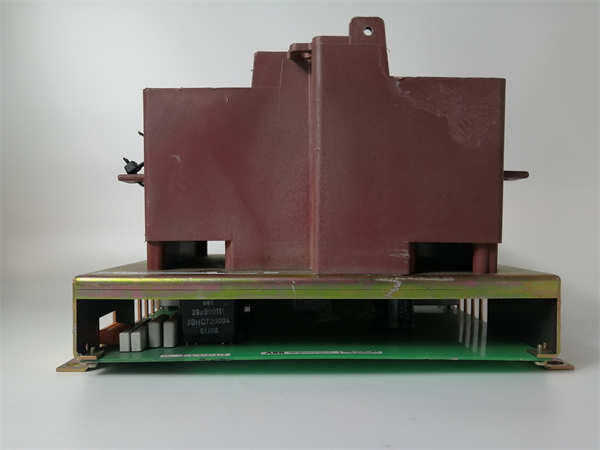

ABB KUC711AE101 3BHB004661R0101

Lifecycle Status and Migration Strategy

ABB has officially discontinued the KUC711AE101 and marked it as obsolete. It is no longer listed in current price books, and factory repair services have been phased out. While some inventory may exist through distributors or brokers, long-term support is not guaranteed, and counterfeit or misrepresented units pose a growing risk.

As an interim measure, operators may stock tested spares or engage certified third parties for board-level repair. However, these approaches become less reliable as component obsolescence deepens.

ABB’s recommended upgrade path is migration to an active AC 800M CPU such as the PM864A or PM891, which offer larger memory, faster processing, native PROFINET, and full redundancy support. This transition typically involves reusing existing I/O modules (where compatible), updating the hardware configuration in Automation Builder, and revalidating control logic. Although requiring engineering effort, the move ensures continued access to software updates, cybersecurity patches, and technical support. For cost-sensitive applications, a staged migration—starting with highest-risk controllers—is advisable to balance operational continuity and lifecycle sustainability.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: