Description

Technical Specifications (For Spare Parts Verification)

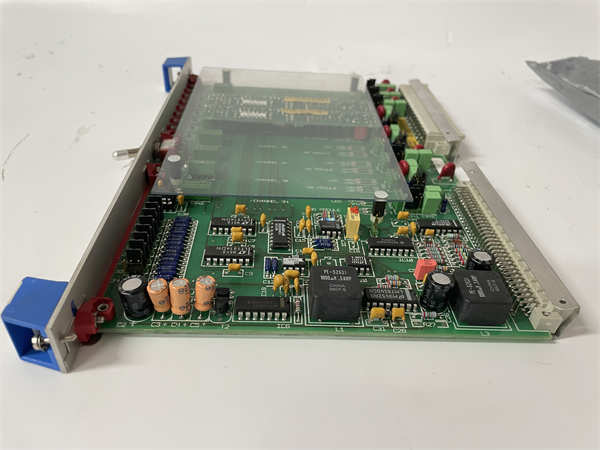

- Product Model: IBA 940143201

- Manufacturer: ABB

- Typical Chemistry: Nickel-Cadmium (NiCd) or Lithium (depending on vintage)

- Nominal Voltage: 3.6 V or 4.8 V (common configurations)

- Capacity: Typically 1.2 Ah to 2.4 Ah

- Connector Type: Polarized plug (e.g., 2-pin Molex or proprietary ABB header)

- Cable Length: ~30–50 cm (varies by installation)

- Operating Temperature: -20°C to +60°C

- Mounting: Internal, secured inside controller or I/O module chassis

- Service Life: 5–10 years (calendar life, regardless of use)

- Compatible Systems: Advant Controller 450, MasterPiece 200/300, early PM5xx protection relays

System Role and Downtime Impact

The IBA 940143201 is installed inside critical control modules—such as the AC 450 CPU or MP300 rack controllers—to maintain volatile memory contents during main power loss. This includes ladder logic, PID tuning constants, alarm histories, and real-time clock settings. If the battery is depleted or fails, any subsequent power cycle will result in a complete memory wipe, forcing the system into a “default” or “factory” state. In a power plant, this could mean loss of boiler sequencing logic or turbine protection settings, requiring hours of reconfiguration and validation before restart. In some cases, the controller may refuse to boot without valid configuration, leading to extended unplanned downtime. Because the battery is often hidden inside sealed modules, its degradation can go unnoticed until a power event occurs.

Reliability Analysis and Common Failure Modes

This battery assembly fails primarily due to natural aging rather than operational stress:

- Capacity fade: NiCd cells suffer from crystalline formation (“memory effect”) and electrolyte dry-out over time, reducing effective runtime below the threshold needed for safe shutdown.

- Open-circuit failure: Internal welds or lead wires fracture due to thermal cycling, causing sudden loss of backup power even if the cell appears intact.

- Leakage or corrosion: Especially in older NiCd packs, electrolyte leakage can damage PCB traces or nearby components, causing secondary failures.

- Voltage sag under load: Aged batteries may show nominal voltage at rest but collapse when asked to power memory circuits during a transition.

A key vulnerability is the lack of low-battery warnings in legacy systems—unlike modern controllers with battery health monitoring. The first sign of failure is often a lost program after a brief outage.

Preventive maintenance recommendations include:

- Replacing the battery proactively every 5–7 years, regardless of apparent condition.

- Verifying backup functionality during scheduled outages by simulating a main power disconnect.

- Inspecting for signs of swelling, leakage, or corrosion during routine module servicing.

- Storing spare batteries in cool, dry conditions to slow self-discharge and aging.

ABB IBA 940143201

Lifecycle Status and Migration Strategy

ABB no longer supplies the IBA 940143201, and original NiCd chemistry is increasingly restricted under environmental regulations (e.g., RoHS). Continuing to use aged batteries poses a silent but severe risk to system integrity.

As an interim solution, qualified vendors offer rebuilt units using modern, compliant cells (e.g., Li-SOCl₂) with matched voltage and form factor. However, these require validation to ensure compatibility with the host module’s charging circuit (if any).

For long-term reliability, the only robust strategy is migration to a supported platform such as System 800xA with AC 800M controllers, which use non-volatile memory (flash-based) and eliminate dependence on backup batteries for configuration retention. This upgrade path removes a critical single point of failure and aligns the facility with current standards for data integrity and cybersecurity. Until then, a disciplined battery replacement program is essential to avoid catastrophic configuration loss.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: