Description

Key Technical Specifications (For Spare Part Verification)

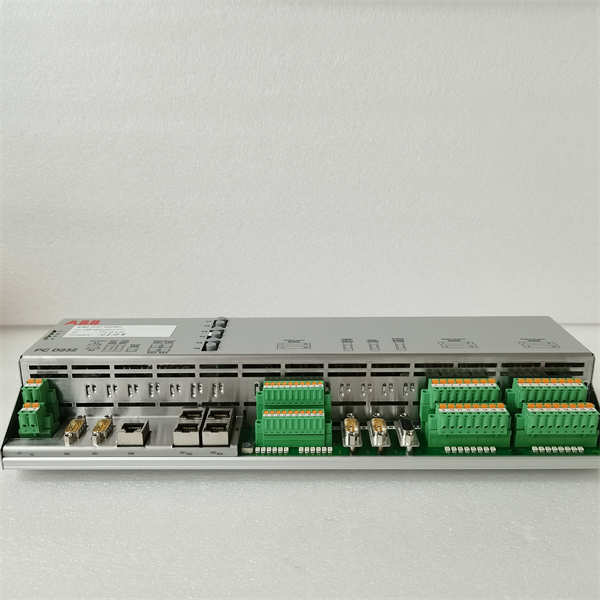

- Product Model: GFD563A102

- ABB Order Code: 3BHE046836R0102

- Manufacturer: ABB

- System Family: UNITROL 6800 / EXC6800 digital excitation platform

- Function: Digitally controlled, isolated gate pulse amplifier for 6- or 12-pulse thyristor bridges

- Input Interface: Digital timing signals via backplane from GVC680 (Generator Voltage Controller) module

- Output: Isolated gate drive signals (typically ±10 V, >2 A peak) per thyristor channel

- Isolation: Reinforced galvanic isolation (>5 kV) between logic and power sides per IEC/EN 61800-5-1

- Channels: Supports up to 12 outputs (configurable for single or dual bridge)

- Diagnostics: Integrated self-test, LED status indicators (Power, OK, Fault), and real-time feedback to controller

- Mounting: Plug-in module in standard EXC6800 chassis (hot-swappable in some configurations)

- Power Supply: Redundant ±15 V and +5 V from system backplane

-

ABB GFD563A102 3BHE046836R0102

System Role and Downtime Impact

The GFD563A102 is a critical actuation interface in ABB’s digital excitation systems, widely deployed on large utility-scale generators (100+ MVA) in thermal, hydro, and nuclear plants. It ensures microsecond-accurate, phase-synchronized firing of thyristors based on commands from the digital regulator—directly influencing terminal voltage stability, reactive power support, and grid compliance during faults.

Unlike older analog boards, the GFD563A102 includes basic health monitoring, but failure still has severe consequences:

- Missing or skewed gate pulses → asymmetric field current → rotor heating

- Complete output loss → loss of excitation → activation of ANSI 40 (Loss-of-Field) relay

- Uncontrolled voltage collapse during load rejection or islanding

Most installations operate with limited or no redundancy at the gate driver level. Thus, a single GFD563A102 failure typically forces an immediate turbine-generator trip, resulting in lost revenue, grid imbalance penalties, and extended outage risk if spares are unavailable.

Reliability Analysis and Common Failure Modes

Despite its digital architecture and improved diagnostics, the GFD563A102 remains susceptible to:

- Gate driver IC degradation: High di/dt switching stresses output transistors, leading to reduced drive strength or intermittent pulses over time.

- Isolation barrier fatigue: Repeated high-voltage transients (e.g., from lightning or switching surges) degrade internal pulse transformers or digital isolators.

- Capacitor aging: Local decoupling capacitors dry out, causing noise on gate signals or reset glitches.

- Backplane connector wear: Thermal cycling induces fretting corrosion in edge connectors, leading to communication dropouts with the GVC680.

- Firmware/hardware mismatch: Mixing incorrect hardware revisions (e.g., R0101 vs. R0102) or outdated firmware can cause incompatibility or erratic behavior.

Preventive maintenance best practices include:

- Monitoring diagnostic LEDs and system logs for “Pulse Fault” or “Module Degraded” alarms

- Performing offline pulse integrity tests using ABB’s Excitation Test Set or equivalent

- Verifying correct order code (3BHE046836R0102) and revision compatibility before installation

- Storing spares in ESD-safe, dry, temperature-controlled environments

Lifecycle Status and Migration Strategy

ABB has officially discontinued the GFD563A102 as part of the evolution toward the UNITROL 8000 platform. While the UNITROL 6800 remains supported, specific submodules like the GFD563A102 are no longer manufactured. ABB may offer last-time buy (LTB) opportunities intermittently, but inventory is scarce.

Short-term mitigation:

- Procure verified-used units from ABB-certified resellers or industrial surplus specialists

- Validate functionality using ABB’s ControlIT or Excitation Commissioning Tool

- Maintain a minimum of two tested spares per critical unit

-

ABB GFD563A102 3BHE046836R0102

Long-term strategic path:

Migrate to UNITROL 8000, which integrates gate drive electronics into more compact, higher-reliability modules with:

- Enhanced cybersecurity (IEC 62443 compliant)

- Advanced predictive diagnostics

- Support for wide-area damping control (WADC)

- Simplified spare parts structure

Migration involves:

- Replacing the EXC6800 chassis with EXC8000

- Updating engineering configuration in PCM600 or ABB Ability™ Electrical Distribution

- Recommissioning PSS, V/Hz limiters, and field current protections

- Conducting full IEEE Std 421.5 performance validation

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: