Description

Technical Specifications (For Spare Parts Verification)

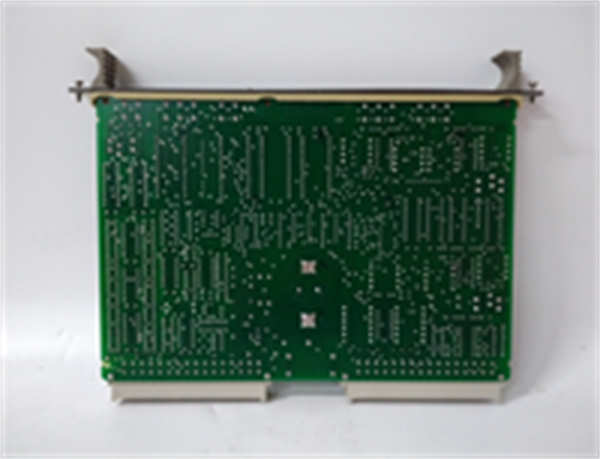

- Product Model: FM9925A-E

- Manufacturer: ABB

- System Compatibility: ABB Advant Controller AC 160 and AC 450

- Bus Type: Profibus DP (EN 50170 / IEC 61158)

- Operating Mode: Configurable as Profibus Master or Slave

- Data Rate: 9.6 kbps to 12 Mbps (software-selectable)

- Physical Interface: 9-pin D-SUB (RS-485), isolated

- Module Format: DIN-rail or rack-mounted carrier with edge connector

- Power Supply: Derived from backplane (+5V, ±12V)

- Diagnostic Indicators: LED status for power, bus activity, and fault

- Firmware Identifier: Typically labeled on EPROM chip (e.g., “FM9925A-E V2.1”)

System Role and Downtime Impact

The FM9925A-E serves as the primary fieldbus gateway in legacy ABB Advant systems, commonly deployed in pulp & paper mills, water treatment plants, and older power generation facilities. It resides in the controller rack and links the central CPU to distributed I/O stations (such as TB5xx series) or intelligent field devices via Profibus DP. If this module fails, all downstream devices on its segment become unreachable—halting data acquisition and control output. In continuous-process environments, this can trigger emergency shutdowns or force manual operation, leading to production loss, safety overrides, or regulatory non-compliance. Given the age of these systems, redundancy was rarely implemented, making the FM9925A-E a single point of failure with high operational consequence.

Reliability Analysis and Common Failure Modes

Despite its industrial-grade design, the FM9925A-E is now well beyond its intended service life (typically 10–15 years). The most prevalent failure mechanisms include: degradation of surface-mount electrolytic capacitors causing power rail instability, corrosion on the backplane edge connector due to humidity ingress, and latch-up damage in the RS-485 transceiver ICs from repeated ESD events during maintenance. A key design vulnerability is the lack of modern surge suppression on the Profibus lines—making the module susceptible to ground potential differences or lightning-induced transients common in outdoor installations.

Preventive actions should focus on environmental control: ensure the cabinet maintains <60% relative humidity and stable temperature. Technicians should periodically inspect for bulging capacitors, clean the backplane fingers with contact cleaner, and verify signal integrity using a Profibus tester (checking for waveform symmetry and noise margin). If the system remains active, installing external Profibus isolators or repeaters can reduce stress on the module’s driver circuitry and extend remaining life.

FM9925A-E ABB

Lifecycle Status and Migration Strategy

ABB has long since retired the FM9925A-E, with no official repair, replacement, or technical support available. Continuing to operate systems dependent on this module carries escalating risk: verified-good spares are dwindling, and untested units may fail shortly after installation. While some industrial surplus vendors offer “as-is” units, functional validation is essential before deployment.

As an interim measure, organizations can pursue board-level repair (e.g., capacitor rework, transceiver replacement) through specialized third-party labs, though success depends on PCB trace integrity. Maintaining a pool of 2–3 tested spares is advisable for critical sites.

For a sustainable path forward, ABB recommends migrating to the AC 800M platform with BSM0400CN00 or CI854A Profibus modules under the System 800xA architecture. This transition requires re-engineering the application logic in Control Builder M and replacing I/O hardware, but delivers modern cybersecurity, diagnostics, and long-term support. Alternatively, for cost-sensitive applications, integrating a standalone Profibus-to-Ethernet gateway (e.g., Hilscher netPI) can bridge the legacy fieldbus to a contemporary PLC, preserving field devices while retiring the AC 160/450 CPU. Early planning is critical—component obsolescence will only accelerate.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: