Description

Key Technical Specifications

| Parameter | Specification |

|---|---|

| Output Type | Electromechanical relays (Form C: Normally Open + Normally Closed) |

| Contact Rating | 250 V AC / 30 V DC, 2 A resistive per channel |

| Isolation | Channel-to-channel and channel-to-backplane isolation via relay architecture |

| Backplane Interface | Connects to AC 800M I/O baseplates (e.g., TB840A, TB850) |

| Termination Requirement | Requires compatible termination unit (e.g., DSTC120 for screw terminals or DSTC160 for spring-clamp) |

| Diagnostic Capability | Basic module status via LED indicators (Power OK, Fault); no per-channel feedback |

| Redundancy Support | Not inherently redundant; redundancy must be implemented at system level (e.g., dual modules controlling same device via logic) |

| Mounting | Standard AC 800M rack with baseplate |

| Certifications | CE, UL, CSA, IEC 61131-2 compliant |

System Role and Operational Impact

The DSSR122 is commonly deployed in applications requiring direct, high-voltage switching without external relays—such as:

- Emergency vent valve actuation

- Firewater pump start commands

- Alarm horn/strobe activation

- Local panel indicator control

- Small motor or heater control in auxiliary systems

Because it uses physical relays, it can switch both AC and DC loads up to its rating, offering flexibility unmatched by solid-state DO modules. However, this also introduces mechanical wear: each relay has a finite life (typically 100,000–500,000 operations), and frequent cycling accelerates contact erosion or welding.

In a failure scenario:

- A stuck-open relay prevents command execution (e.g., valve won’t open during ESD)

- A welded-closed relay may cause unintended actuation (e.g., pump starts unexpectedly)

- No per-channel diagnostics mean faults are often only detected during functional testing or process deviation

Since the DSSR122 is passively monitored, a failed relay may go unnoticed until needed—posing latent risk in safety-critical loops.

Reliability & Common Failure Modes

Despite robust design, the DSSR122 exhibits predictable aging issues after 10–15 years:

- Relay Contact Degradation

- Arcing during load switching erodes contacts, increasing resistance or causing intermittent connection

- Inductive loads (e.g., solenoids) accelerate wear if not properly suppressed

- Coil Driver Failure

- Internal transistor or driver IC fails due to thermal stress, preventing relay energization

- Mechanical Fatigue

- Repeated operation leads to spring weakening or armature misalignment

- Termination/Baseplate Issues

- Corrosion or loose connections in the DSTC120/160 termination block mimic DO failures

- LED or Status Circuit Faults

- False “OK” indication masks internal failure

Recommended Maintenance:

- Perform annual functional tests using 800xA or manual forcing

- Use snubber circuits or flyback diodes on inductive loads to extend relay life

- Monitor operation counters (if logged in application logic)

- Replace units showing excessive click delay or inconsistent response

-

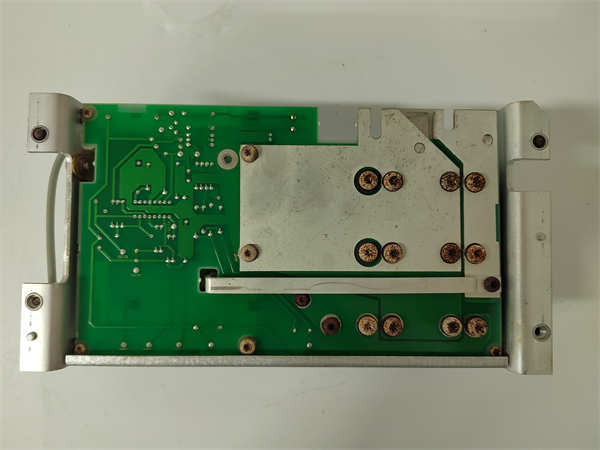

ABB DSSR122 48990001-NK

Lifecycle Status & Migration Strategy

ABB has discontinued the DSSR122 (48990001-NK) with no direct replacement in current AC 800M portfolios. Newer systems favor solid-state digital outputs (e.g., DSQCxxxx series) or remote I/O with Ethernet for reduced maintenance.

However, solid-state modules cannot directly switch AC loads or provide true galvanic isolation per channel, making migration non-trivial.

Short-Term Mitigation:

- Maintain tested spares with matching firmware/baseplate compatibility

- Archive termination block layouts and wiring diagrams

- Avoid mixing DSSR122 batches—relay characteristics may vary slightly

Long-Term Migration Options:

- Replace with Solid-State DO + External Relays

- Use modern DO modules (e.g., DSAI146) to drive panel-mounted industrial relays (e.g., Phoenix Contact, Omron)

- Preserves AC switching capability while leveraging newer I/O architecture

- Upgrade to S800 I/O Platform

- Transition to S800 I/O with DO810/DO811 modules and external relay packs

- Enables remote I/O, better diagnostics, and PROFINET/Ethernet integration

- Hybrid Approach for Safety Loops

- For SIL-rated functions, consider dedicated safety relays or Triconex/SIS solutions instead of general-purpose DO

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: