Description

Technical Specifications (For Spare Parts Verification)

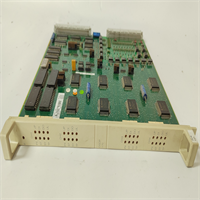

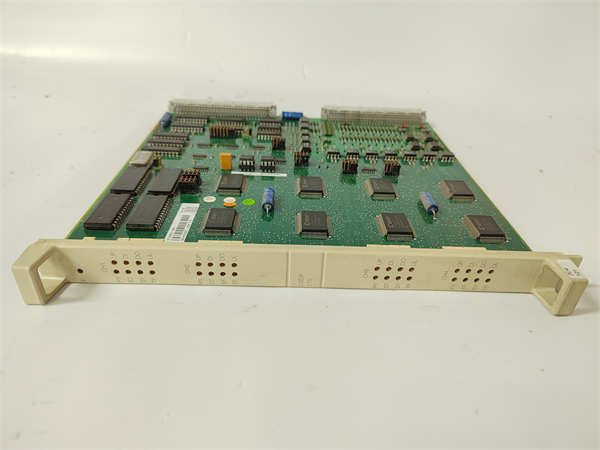

- Product Model: DSDP170

- Manufacturer: ABB

- Order Code: 57160001-ADF

- System Platform: Advant Controller 450 (AC 450), MasterPiece 200/300, early System 800xA (legacy integration)

- I/O Configuration: 32 channels, software-configurable per channel as 24 VDC digital input or output

- Input Voltage Range: 18–30 VDC (nominal 24 VDC)

- Output Type: Sourcing (PNP), max 0.5 A per channel, 4 A total per module

- Isolation: Group isolation (channels grouped in blocks of 8), no channel-to-channel isolation

- Backplane Interface: Proprietary parallel bus via AC 450 I/O chassis (e.g., CI450 rack)

- Diagnostic Capability: Basic LED indication per channel; no detailed fault logging in controller

- Operating Temperature: 0°C to +60°C

- Mounting: DIN-rail compatible within ABB I/O subrack

System Role and Downtime Impact

The DSDP170 is typically installed in remote I/O racks connected to the central AC 450 CPU via redundant fieldbus (e.g., PROFIBUS FMS or proprietary MB300). It serves as the primary interface for discrete field signals—such as valve position confirmations, pump run status, or emergency stop contacts—in power plants, pulp & paper mills, and heavy industrial facilities. In boiler control, for example, loss of flame scanner feedback due to a failed DSDP170 input could trigger a false “flame loss” trip, causing an unplanned boiler shutdown. Similarly, a stuck output might prevent a critical isolation valve from closing during a safety event. Because the AC 450 lacks modern hot-swap or granular diagnostics, a single faulty module can disable up to 32 control points, potentially cascading into a full unit outage or process line stoppage.

Reliability Analysis and Common Failure Modes

Despite its robust industrial design, the DSDP170 is vulnerable to age-related degradation after decades of service. Common failure modes include:

- Output transistor burnout due to inductive load back-EMF (e.g., from un-suppressed relay coils), especially in older installations lacking flyback diodes.

- Input optocoupler degradation from sustained overvoltage or ground potential rise, leading to signal dropout or false triggering.

- Corrosion on DIN rail mounting clips or backplane connectors, increasing contact resistance and causing intermittent communication loss.

- PCB trace delamination or solder joint cracking from thermal cycling in high-ambient environments.

A key design limitation is the lack of individual channel protection—failure in one output group can affect adjacent channels. Additionally, the module contains electrolytic capacitors that dry out over time, reducing noise immunity and increasing susceptibility to voltage transients.

Preventive maintenance should focus on:

- Periodic inspection of field wiring for proper surge suppression and grounding.

- Verifying 24 VDC power quality at the I/O rack (ripple < 5%, stable under load).

- Testing channel functionality during planned outages using loop simulation.

- Monitoring system logs for “I/O Rack Communication Fault” or repeated scan errors that may indicate early module degradation.

DSDP170 57160001-ADF ABB

Lifecycle Status and Migration Strategy

ABB has long since ended all manufacturing, repair, and technical support for the AC 450 platform and DSDP170 module. Continuing to operate this hardware carries significant operational and financial risk: spare parts are scarce, pricing is volatile, and failure recovery times are unpredictable.

As a short-term mitigation, operators should:

- Audit and functionally test all existing spares.

- Partner with specialized vendors offering burn-in tested, calibrated replacements.

- Implement enhanced monitoring of I/O health via legacy SCADA trend logs.

For sustainable operation, ABB’s official migration path is a full transition to the AC 800M platform within System 800xA. This involves replacing the AC 450 CPU, I/O modules (e.g., with DI810/D0810), and field wiring terminations, along with re-engineering control logic in Control Builder M. While requiring capital investment, this upgrade delivers improved cybersecurity, remote access, predictive diagnostics, and long-term vendor support. Facilities planning to operate beyond 2030 should prioritize this migration to eliminate obsolescence exposure across the control infrastructure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: