Description

Key Technical Specifications (For Spare Parts Verification)

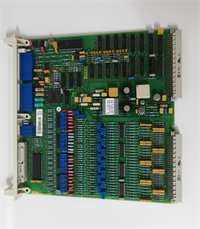

- Product Model: DSAI130D 3BSE003127R1

- Manufacturer: ABB

- System Platform: ABB AC 800F (part of System 800xA distributed control system)

- Input Channels: 8 isolated channels

- Input Range: Configurable per channel for 4–20 mA (loop-powered) or ±10 V / 0–10 V

- Accuracy: ±0.1% of full scale at 25°C

- Isolation: Channel-to-channel and channel-to-bus isolation (500 VAC RMS)

- Update Rate: ~10 ms per channel (system-dependent)

- Backplane Interface: Connects via DSCS130 or DSCS140 I/O station backplane

- Power Consumption: Approx. 2.5 W from +5 VDC backplane supply

- Diagnostic Features: Open-circuit detection for 4–20 mA inputs; module OK LED

- Physical Label: Must display “DSAI130D” and “3BSE013127R1” (note: common mislabeling as 3BSE003127R1; correct ABB part number is 3BSE013127R1)

System Role and Downtime Impact

The DSAI130D is a foundational analog input module in ABB’s AC 800F-based DCS installations, commonly deployed in power plants, refineries, and chemical facilities where continuous process monitoring is essential. It resides in remote I/O stations (e.g., DSCS130 cabinets) and converts field sensor signals into digital data for the AC 800F CPU. Because it handles multiple critical loops—such as boiler drum level, turbine exhaust temperature, or reactor pressure—a single module failure can degrade or disable several control functions simultaneously. In safety-instrumented applications, this may force a controlled shutdown to maintain regulatory compliance. Given that AC 800F systems often operate beyond their original design life, the unavailability of this module directly threatens operational continuity.

Reliability Analysis and Common Failure Modes

Although solid-state in design, the DSAI130D is susceptible to several age-related failure mechanisms. The most prevalent issue is degradation of the precision analog front-end components—particularly the instrumentation amplifiers and voltage references—leading to signal drift or nonlinearity. Electrolytic capacitors on the internal DC/DC converter age over time, especially in high-temperature environments, causing intermittent power dropout or increased noise on input channels. Field wiring terminals can develop corrosion due to sulfur compounds or humidity, increasing contact resistance and inducing measurement errors that mimic sensor faults. Additionally, the module lacks modern transient protection; repeated exposure to ground loops or switching surges can damage input protection diodes, resulting in shorted or open channels.

As part of preventive maintenance, technicians should perform annual loop calibration checks using a certified current source, verify open-circuit diagnostics via Control Builder F, and inspect terminal tightness (recommended torque: 0.6 Nm). Thermal imaging during peak load can reveal overheating components. Since the module has no battery or firmware, failures are typically hardware-based and irreversible without board-level repair.

ABB DSAI130D 3BSE003127R1

Lifecycle Status and Migration Strategy

ABB has formally obsoleted the DSAI130D (correct P/N: 3BSE013127R1) as part of the broader retirement of the first-generation AC 800F I/O portfolio. No factory-new units are available, and ABB no longer provides repair services or technical documentation for troubleshooting. Continued reliance on this module poses significant operational risk due to dwindling spares, escalating costs, and potential counterfeit units lacking proper calibration.

In the short term, facilities can mitigate exposure by auditing existing spares, consolidating unused modules from decommissioned racks, or engaging vendors who offer functional testing and burn-in validation. However, these are temporary measures.

ABB’s official migration path is to upgrade to the AC 800M platform with AI840 (3BSE022180R1) or AI845 (3BSE020876R1) analog input modules. This transition requires:

- Replacing I/O stations with AC 800M-compatible racks (e.g., TB850 baseplates)

- Rewiring field connections to new terminal blocks

- Updating control logic in Control Builder M to reflect new I/O addressing

- Recommissioning all affected loops

While this involves engineering effort, it restores access to ABB support, extends system life by 10–15 years, and enables integration with modern cybersecurity and IIoT standards. For sites unable to fund full migration, maintaining a strategic reserve of at least two fully tested DSAI130D modules—verified for accuracy, isolation, and diagnostic function—is the only viable interim strategy.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: