Description

Key Technical Specifications (For Spare Part Verification)

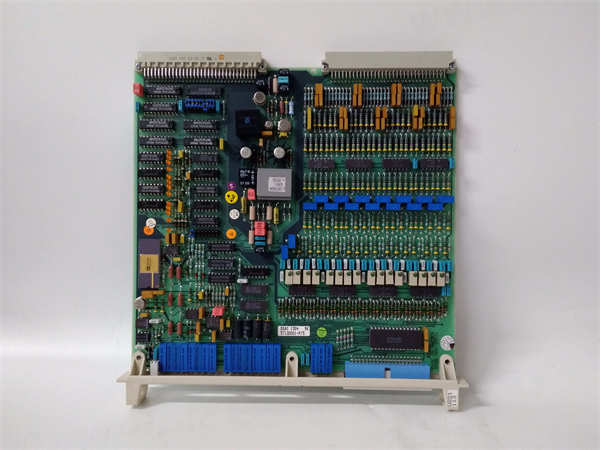

| Parameter | Specification |

|---|---|

| Module Type | DSAI130 |

| ABB Order Code | 57120001-P5 |

| System Compatibility | ABB Advant Controller AC 110 / AC 160 (Advant OCS) |

| Input Channels | 8, single-ended or differential (configurable via jumpers) |

| Signal Types | 0/4–20 mA (loop-powered or passive), 0–10 V, ±10 V |

| Input Impedance | ~250 Ω (current), >100 kΩ (voltage) |

| Isolation | Channel-to-backplane isolation (typically 500 VDC); no channel-to-channel isolation |

| Accuracy | ±0.1% of full scale (typical at 25°C) |

| Update Rate | ~100 ms per channel (system-dependent) |

| LED Indicators | Power OK, Module OK, and per-channel fault (varies by revision) |

| Mounting | DIN-rail mounted in Advant-specific I/O chassis with proprietary backplane |

| Power | Supplied via backplane (±15 VDC, +5 VDC logic) |

-

DSAI130 57120001-P5

System Role and Downtime Impact

The DSAI130 was a workhorse analog input module in ABB’s Advant OCS systems, widely deployed in power plants, refineries, and industrial facilities from the late 1980s through the early 2000s. It directly interfaces with field transmitters to digitize critical process variables such as boiler drum level, turbine lube oil pressure, or feedwater flow. These signals feed into regulatory control loops, safety interlocks, and operator displays.

If the DSAI130 fails—due to ADC drift, power supply degradation, or backplane communication loss—the associated measurements become stale or invalid. In non-redundant systems (common in Advant OCS), this can:

- Force control loops into manual mode

- Trigger high/low alarm cascades

- Disable automatic startup sequences

- In extreme cases, initiate a process trip if the signal is part of a protective function (e.g., high bearing temperature shutdown)

Because Advant OCS lacks modern diagnostic capabilities, failures often go undetected until operational impact occurs.

Reliability Analysis and Common Failure Modes

Despite robust construction, the DSAI130 is now operating 20–35 years beyond its design life. Key aging-related vulnerabilities include:

- Analog front-end drift: Precision resistors and op-amps degrade over time, introducing offset or gain errors that compromise measurement accuracy—often without triggering module fault indicators.

- Electrolytic capacitor aging: Onboard filtering capacitors dry out, increasing noise susceptibility and causing intermittent readings, especially in high-EMI environments.

- Backplane connector corrosion: Oxidation on the edge connector leads to poor contact resistance, resulting in communication timeouts or complete module dropout.

- Jumper misconfiguration or loosening: Vibration can dislodge internal jumpers, silently changing input scaling (e.g., interpreting 4–20 mA as 0–10 V).

- Overvoltage damage: Lack of modern transient protection makes the module vulnerable to surges from field wiring (e.g., lightning-induced spikes).

Recommended preventive actions:

- Perform annual calibration verification using a certified mA/V calibrator

- Inspect for bulging capacitors or discoloration on the PCB

- Clean backplane contacts with electronic-grade contact cleaner

- Secure and document all internal jumper positions

- Ensure proper shield grounding on field cables to reduce noise

-

DSAI130 57120001-P5

Lifecycle Status and Migration Strategy

ABB discontinued the Advant OCS platform in the early 2000s, replacing it with the AC 800M-based System 800xA. The DSAI130 has no direct replacement, and new units have been unavailable for over two decades.

Short-term risk mitigation:

- Maintain a small inventory of tested and calibrated spares under climate-controlled storage

- Implement redundant measurements for critical loops using external recorders or HMI trend comparisons

- Avoid unnecessary module hot-swaps—always power down the I/O rack

Long-term migration path: ABB strongly recommends migrating to System 800xA with S800 I/O, using modern analog input modules such as:

- UCD224A105 (4-channel, HART-enabled)

- UCD227A (8-channel, high-density)

This migration requires:

- Re-engineering the control application in Control Builder M

- Rewiring field connections to new I/O terminals

- Re-commissioning all analog loops

- Operator retraining

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: