Description

Key Technical Specifications (For Spare Part Verification)

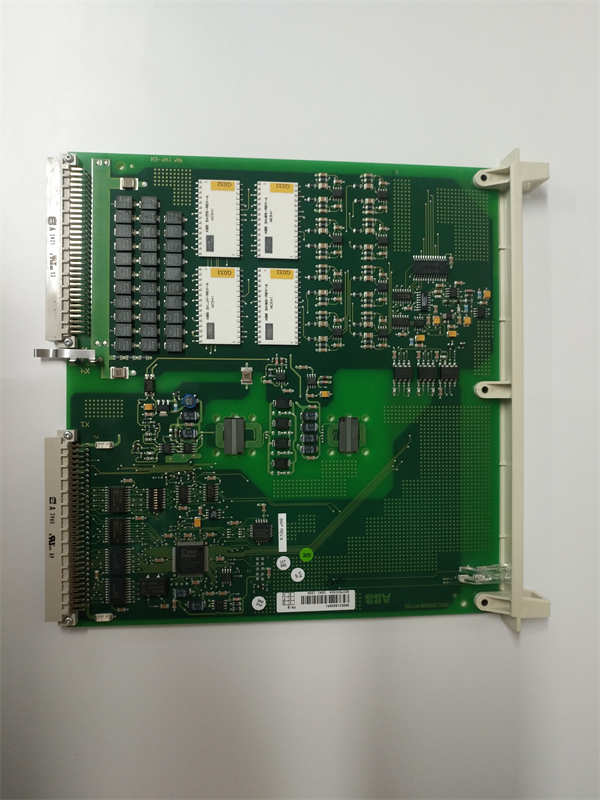

- Model: DSAI 130A

- Manufacturer: ABB

- System Platform: Advant Controller (MasterView, MOD 300) and early AC 800M (with compatibility mode)

- Input Channels: 16 single-ended or 8 differential

- Input Signal Range: ±10 V, 0–20 mA, 4–20 mA (software-configurable per channel)

- Resolution: 14-bit A/D conversion

- Isolation: Channel-to-bus isolation (500 V RMS)

- Backplane Power Consumption: Approx. 1.2 W

- Mounting: DIN rail in I/O subrack (e.g., TK801V001)

- Diagnostic Features: Module OK LED, no per-channel diagnostics

- Order Code: 3BSE018292R1 (critical for exact replacement verification)

System Role and Impact of Failure

The DSAI 130A serves as a foundational analog input interface in legacy ABB control systems, commonly deployed in power generation, pulp & paper, and heavy industrial facilities installed between the late 1990s and early 2010s. It converts field sensor signals into digital data for the controller, enabling closed-loop regulation of key processes. Because it typically handles multiple critical measurements—such as boiler drum level, turbine bearing temperature, or reactor pressure—a complete module failure can disable an entire control loop group. In safety-critical applications, this may trigger automatic trips or force operators into manual control, increasing human error risk. Given its integration depth, replacing a failed unit without a verified spare often results in extended downtime, especially if system documentation is outdated or personnel familiarity has eroded.

Reliability Analysis and Common Failure Modes

The DSAI 130A is generally robust but susceptible to age-related degradation. The most frequent failure points are the input protection circuitry and the internal DC/DC converter that provides channel isolation. Over time, repeated exposure to voltage transients from field wiring—especially in unshielded or poorly grounded installations—can degrade transient voltage suppression (TVS) diodes, leading to erratic readings or total channel loss. Additionally, the electrolytic capacitors on the power section tend to dry out after 10–15 years of continuous operation, causing power instability or spontaneous resets.

A notable design limitation is the lack of per-channel diagnostic feedback; the module only reports a general “OK” status, making it difficult to isolate a single faulty channel without physical signal substitution. Environmental factors also play a role: high ambient temperatures accelerate capacitor aging, while humidity can induce corrosion on terminal blocks. As preventive maintenance, it is advisable to periodically verify calibration using a precision current source, inspect terminal tightness, and ensure proper grounding of the I/O rack. Keeping a known-good spare under controlled storage conditions is strongly recommended.

ABB DSAI 130A 3BSE018292R1

Lifecycle Status and Migration Strategy

ABB officially discontinued the DSAI 130A several years ago, classifying it as obsolete with no direct active replacement. While the module was partially compatible with early AC 800M systems via legacy racks, ABB’s current roadmap focuses exclusively on the AC 800M High-Density and Smart I/O platforms. Continuing to operate systems dependent on the DSAI 130A carries significant risk: spare parts are increasingly scarce, technical support from ABB is limited to paid legacy contracts, and cybersecurity updates are unavailable.

In the short term, facilities should audit their installed base, identify single points of failure, and secure tested spares from reputable suppliers who perform functional validation. Some users have implemented external signal conditioners or redundant sensors to mitigate channel loss impact. For long-term sustainability, a staged migration to modern AC 800M I/O (e.g., AI810 or AI880 modules) is the most viable path. This typically involves replacing I/O subracks, re-mapping signal wiring, and updating control logic—but delivers improved accuracy, full diagnostics, and future-proof support. ABB offers migration services, including signal mapping tools and configuration conversion assistance, to reduce engineering effort. Early planning is essential to avoid forced outages due to sudden hardware failure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: