Description

Key Technical Specifications (For Spare Part Verification)

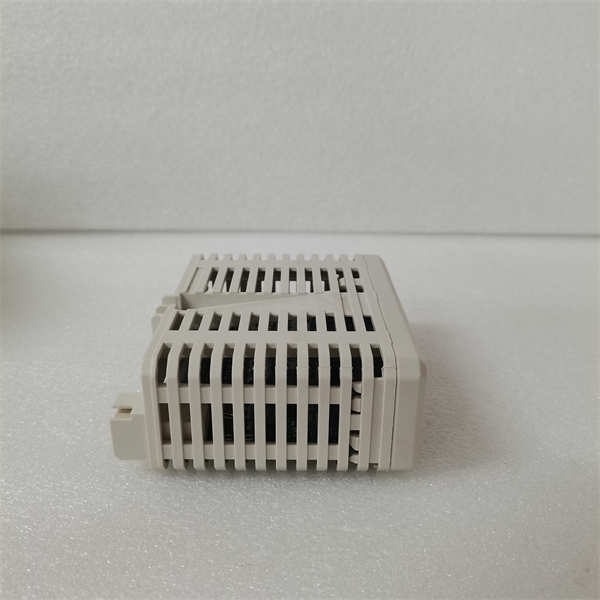

- Product Model: DO810

- ABB Order Code: 3BSE008510R1

- Manufacturer: ABB

- System Family: AC 800M (within 800xA distributed control system)

- Output Channels: 16 relay-based digital outputs

- Contact Type: Form C (changeover / SPDT) per channel

- Switching Capacity: Typically 250 V AC / 2 A or 30 V DC / 2 A (resistive load)

- Isolation: Relay-based galvanic isolation between logic and field sides (>2.5 kV)

- Response Time: <10 ms (relay mechanical limitation)

- Diagnostics: LED indicator per channel; status accessible via Control Builder M

- Mounting: DIN rail or rack-mounted within AC 800M I/O station

- Power: Supplied via backplane; relay coils powered internally

ABB DO810 3BSE008510R1

System Role and Downtime Impact

The DO810 serves as a key actuation interface in legacy ABB 800xA systems deployed in power plants, water treatment facilities, and industrial process lines. It directly controls field devices that execute critical actions—such as opening emergency vents, starting backup pumps, or energizing alarm horns. Because it uses electromechanical relays, it is often specified in applications requiring high-voltage switching or fail-safe behavior (e.g., de-energize-to-trip). A failed DO810 can result in the inability to command essential equipment, potentially disabling safety responses or halting production sequences. In non-redundant configurations—which are common due to historical design practices—the loss of a single DO810 module may compromise multiple independent control loops, leading to partial or full plant shutdown.

Reliability Analysis and Common Failure Modes

Despite robust construction, the DO810 is subject to predictable wear mechanisms due to its electromechanical nature:

- Relay contact welding or pitting: Caused by inductive loads (e.g., solenoids) without proper suppression, leading to stuck-on or high-resistance states.

- Coil burnout: From sustained overvoltage, repeated cycling beyond rated life (~100,000 operations), or internal short circuits.

- Terminal corrosion: Moisture or chemical exposure oxidizes screw terminals, increasing resistance and causing overheating.

- Mechanical fatigue: Relay armatures lose spring tension over time, resulting in slow or incomplete switching.

- Backplane connector degradation: Thermal cycling induces micro-cracks, causing intermittent communication with the CPU.

A notable vulnerability is the lack of built-in arc suppression on the field side—users must provide external diodes or RC snubbers for inductive loads, which is often overlooked during maintenance. Preventive measures include:

- Periodic functional testing under actual load conditions

- Inspection of relay status LEDs and contact resistance measurements

- Verification of external suppression components on inductive circuits

- Storage of verified spares in dry, vibration-free environments to preserve relay mechanics

ABB DO810 3BSE008510R1

Lifecycle Status and Migration Strategy

ABB has discontinued the DO810. It is no longer listed in active catalogs, and official support is limited to archived documentation. No factory repairs, recalibration, or firmware updates are available. Continued use introduces operational, safety, and compliance risks—particularly as relay modules age beyond their mechanical life expectancy.

Short-term mitigation includes sourcing tested-used units from certified industrial surplus vendors or engaging specialized repair services capable of replacing individual relays and validating switching performance.

The recommended long-term migration path is to replace the DO810 with ABB’s current-generation DO820 (transistor output) or DO840 (relay output) modules, which offer improved diagnostics, higher reliability, and compatibility with modern 800xA system platforms. The DO840, in particular, provides updated relay technology with longer mechanical life and integrated surge protection.

Migration typically involves:

- Replacing the module and verifying wiring compatibility (note: pinout and terminal layout may differ)

- Updating hardware configuration in Control Builder M

- Re-commissioning associated control logic and interlocks

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: