Description

Key Technical Specifications (For Spare Parts Verification)

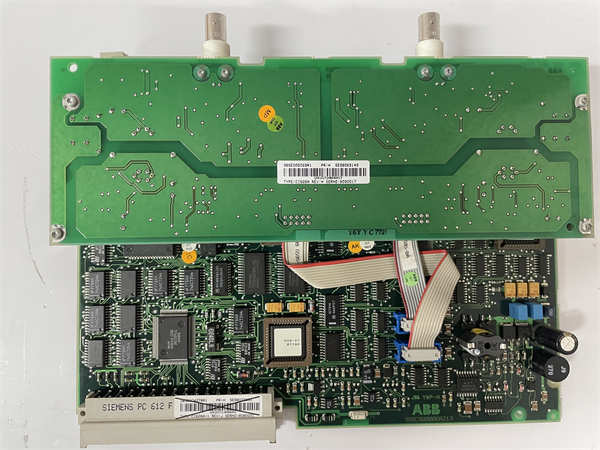

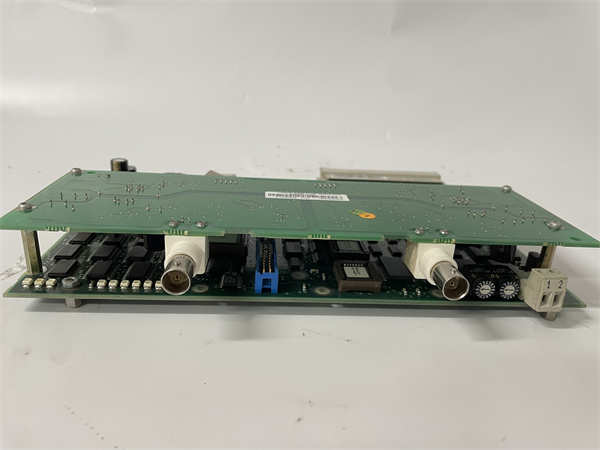

- Product Model: CI626A

- Order Code: 3BSE005029R1

- Manufacturer: ABB (Process Automation, now Hitachi Energy)

- System Platform: AC 800M Controller (used in Symphony Plus, Melody, and custom DCS/PLC architectures)

- Communication Protocol: PROFIBUS DP (Class 1 and Class 2)

- Operating Mode: Configurable as PROFIBUS Master or Slave

- Data Rate: Adjustable from 9.6 kbps to 12 Mbps

- Max. Connected Devices: Up to 126 slaves per segment (system-dependent)

- Electrical Interface: RS-485 via 9-pin D-sub connector (isolated)

- Isolation Voltage: 500 VAC between logic and field sides

- Diagnostic Features: LED indicators for power, communication activity, and fault; detailed diagnostics accessible via Control Builder M

- Mounting: DIN rail with standard AC 800M backplane

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The CI626A is a critical communication enabler in legacy ABB AC 800M systems that rely on PROFIBUS DP for distributed I/O connectivity—common in power plants, water treatment facilities, and industrial process lines. It acts as the sole bridge between the central controller and remote I/O stations (such as S800 modules mounted in field junction boxes), motor control centers (MCCs), or intelligent field devices like drives and valve positioners. A failure of the CI626A results in complete loss of communication with all downstream PROFIBUS nodes, effectively disabling entire process sections. In a boiler system, this could mean loss of feedwater pump status, damper feedback, and burner control—triggering a forced trip. Unlike redundant Ethernet-based systems, many PROFIBUS installations operate without backup links, making the CI626A a single point of failure with high operational consequence.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the CI626A is susceptible to several age- and environment-related failure mechanisms:

- RS-485 transceiver degradation: The isolated RS-485 driver/receiver ICs degrade due to repeated exposure to ground potential differences, lightning-induced surges, or improper termination, leading to intermittent communication or complete bus dropout.

- Isolation barrier failure: The optocouplers or digital isolators that protect the controller from field-side transients can fail shorted or open, either exposing the backplane to damage or blocking all data.

- Firmware corruption: Though rare, the onboard configuration memory can become corrupted after extended operation without power cycling, causing the module to boot into an undefined state.

- Connector and PCB damage: Repeated plugging/unplugging or vibration can loosen the D-sub connector pins or crack solder joints, especially in high-noise environments with poor cable strain relief.

Recommended maintenance practices include:

- Verifying proper PROFIBUS termination (120 Ω at both ends) and shield grounding (single-point earth).

- Monitoring bus error counters via Control Builder M during routine checks.

- Inspecting the D-sub connector for bent pins or corrosion.

- Keeping spare modules powered periodically to maintain firmware integrity and capacitor health.

ABB CI626A 3BSE005029R1

Lifecycle Status and Migration Strategy

ABB (Hitachi Energy) has formally obsoleted the CI626A as part of its strategic shift toward Ethernet-based field networks (PROFINET, Modbus TCP). No new production exists, and official repair or replacement services are discontinued. Continued use introduces significant risk due to shrinking spare availability and the prevalence of untested units in the gray market.

Interim mitigation strategies:

- Source only from suppliers who perform full functional validation—including bus master/slave operation, error handling, and diagnostic reporting—on live PROFIBUS test benches.

- Maintain at least one tested spare per critical controller.

- Implement external PROFIBUS repeaters with isolation to reduce stress on the CI626A port.

Long-term migration path:

Hitachi Energy recommends migrating to the CI874 (3BSE048728R1) PROFINET communication module, which supports modern Ethernet-based I/O (e.g., S800 over PN) and offers superior bandwidth, diagnostics, and cybersecurity. This transition requires:

- Replacement of the CI626A with CI874 in the AC 800M rack.

- Rewiring field devices to PROFINET switches or replacing PROFIBUS I/O with PROFINET equivalents.

- Updating I/O configuration in Control Builder M and reassigning network addresses.

For facilities not ready for full fieldbus replacement, using a PROFIBUS-to-PROFINET gateway (e.g., Anybus X-gateway) can extend the life of existing PROFIBUS devices while connecting them to a modern CI874-based backbone. However, this adds latency and complexity. In most cases, maintaining a rigorously validated spare pool of CI626A remains the pragmatic short-to-medium-term solution to avoid unplanned downtime.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: