Description

Key Technical Specifications (For Spare Parts Verification)

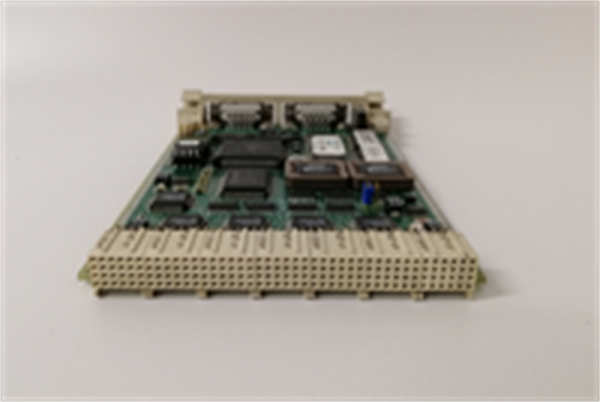

- Product Model: CI535V30

- Manufacturer: ABB

- Order Code: 3BSE022162R1

- System Platform: AC 800M (integrated in 800xA Process Automation System)

- Communication Standard: PROFIBUS DP (IEC 61158)

- Operating Modes: Master or Slave (configurable via Control Builder M)

- Data Rate: Up to 12 Mbps (auto-baud detection)

- Max. Connected Slaves: 126 (per PROFIBUS standard)

- Redundancy Support: Yes – supports redundant CI535V30 pairs with automatic failover

- Backplane Interface: AC 800M CI854A or CI854B baseplate

- Diagnostic Features: LED indicators for PWR, RUN, COM, and BF (bus fault); detailed diagnostics via 800xA

- Firmware Dependency: Requires compatible Control Builder M version (typically CBM 4.x or earlier)

System Role and Downtime Impact

The CI535V30 serves as the primary PROFIBUS DP interface in an AC 800M controller station, enabling communication with a wide range of field devices—including remote I/O stations (e.g., ET200M), variable frequency drives (VFDs), and smart valves. In redundant configurations, two CI535V30 modules operate in hot standby to ensure continuous fieldbus availability.

If the active CI535V30 fails and redundancy is either absent or compromised, all PROFIBUS-connected devices become unreachable. While local hardwired I/O may continue to function, any loop relying on PROFIBUS data (e.g., motor status, analog feedback from remote transmitters) will fail safe or freeze. In processes like water treatment or batch manufacturing, this can trigger interlocks, cause product loss, or force a partial shutdown. Recovery requires hardware replacement and re-downloading of the communication configuration—a process that can take 1–2 hours even with proper backups.

Reliability Analysis and Common Failure Modes

The CI535V30 is generally robust but exhibits age-related vulnerabilities common to industrial communication modules. The most frequent failure is damage to the RS-485 transceiver circuitry due to ground potential differences, electrical surges, or incorrect cable shielding—especially in plants with long PROFIBUS trunk lines. Such damage often manifests as intermittent bus faults (BF LED flashing) before complete communication loss.

Another risk is firmware incompatibility during partial system upgrades. If the CI535V30’s firmware version does not align with the AC 800M CPU or Control Builder M project, the module may fail to initialize or report spurious errors. Additionally, the 9-pin SUB-D connector is prone to mechanical wear and corrosion over time, particularly in high-vibration environments.

Recommended preventive actions include:

- Verify PROFIBUS cable integrity and grounding annually—ensure single-point grounding and proper termination.

- Monitor the BF (Bus Fault) diagnostic bit in 800xA for early signs of communication instability.

- Maintain consistent firmware versions across all CI535V30 and CPU modules in redundant pairs.

- Use conformal coating or protective boots on the SUB-D connector in harsh environments.

ABB CI535V30 3BSE022162R1

Lifecycle Status and Migration Strategy

ABB formally discontinued the CI535V30 in 2021 as part of its strategic shift toward Ethernet-based field networks (e.g., PROFINET, EtherNet/IP). Continuing to use it introduces supply chain risk and limits future integration options.

As a short-term measure, facilities may acquire verified NOS units from authorized ABB partners, but each should undergo full functional testing—including redundancy switchover and max-slave load simulation—before installation.

ABB’s recommended migration path is to replace the CI535V30 with the CI854A or CI854B communication module, which supports PROFINET IO natively. This transition requires:

- Replacing PROFIBUS field devices with PROFINET equivalents (or using PROFINET-to-PROFIBUS gateways for legacy slaves)

- Updating the Control Builder M project to use PROFINET communication objects

- Reconfiguring network topology (switches, IP addressing)

While this entails engineering effort, it aligns the system with modern industrial networking standards, improves bandwidth and diagnostics, and ensures long-term supportability. For sites with extensive PROFIBUS infrastructure, a hybrid approach—using gateways for non-critical devices while migrating core loops to PROFINET—offers a balanced risk-reduction strategy.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: