Description

Technical Specifications (For Spare Part Verification)

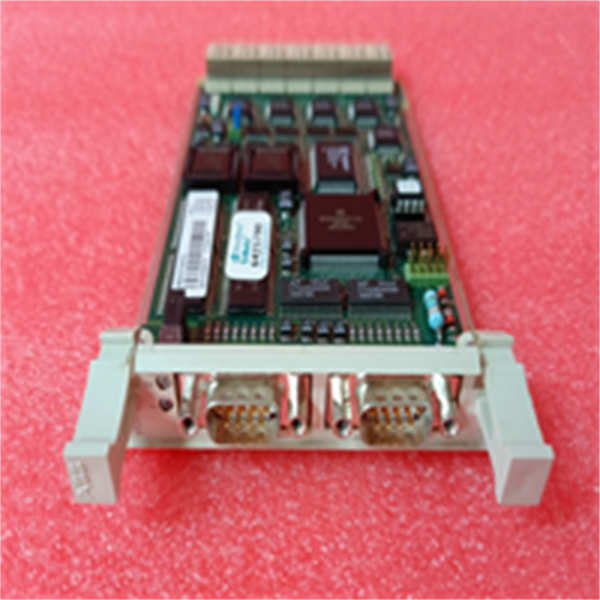

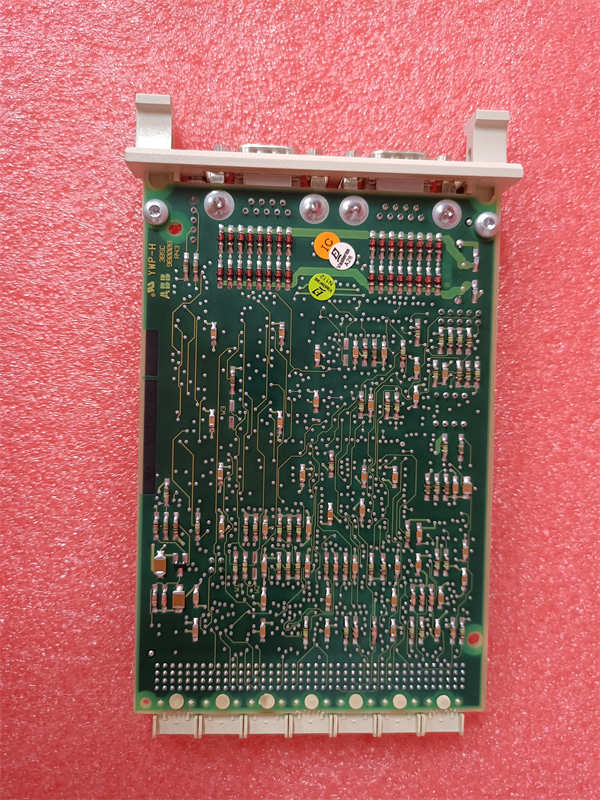

- Product Model: CI532V05

- Manufacturer: ABB

- System Family: AC 800M Distributed Control System (DCS)

- Communication Protocol: PROFIBUS DP (Master or Slave mode, configurable)

- Data Rate: Up to 12 Mbps (auto-baud or fixed)

- Physical Interface: 9-pin D-SUB (RS-485), isolated

- Backplane Connection: Proprietary ABB I/O bus (mounts in standard AC 800M I/O rack)

- LED Indicators: PWR, RUN, COM, BF (Bus Fault), and module status

- Power Consumption: Approx. 3 W (from backplane 24 VDC)

- Firmware Dependency: Must match project configuration in Control Builder M (e.g., firmware v2.1 required for GSD file compatibility)

- Supported Devices: Compatible with ABB TB5xx/TB8xx I/O modules, ACS800/880 drives, and third-party PROFIBUS slaves using standard GSD files

System Role and Downtime Impact

The ABB CI532V05 functions as a critical fieldbus communication adapter within the AC 800M architecture, commonly deployed in power plants, pulp & paper mills, and mining operations commissioned between 2000 and 2012. It enables the central controller to exchange cyclic I/O data with remote PROFIBUS DP nodes—such as motor control centers, valve terminals, or variable frequency drives—over a single twisted-pair cable. In many legacy designs, this module is the only link to an entire subsystem (e.g., a conveyor line or boiler feedwater system). If the CI532V05 fails due to electrical surge, firmware corruption, or internal component degradation, all connected devices become unreachable. This typically triggers process alarms, disables automatic control loops, and may force operators into manual backup mode or cause a localized shutdown. In non-redundant configurations, the absence of a verified spare directly translates to extended downtime.

Reliability Analysis and Common Failure Modes

Although designed for industrial use, the CI532V05 exhibits age-related vulnerabilities typical of early-2000s fieldbus electronics. The most common failure is damage to the RS-485 transceiver IC due to ground potential differences or lightning-induced surges on the PROFIBUS cable—especially in installations lacking proper shielding or grounding. Internal flash memory can also degrade over time, leading to boot failures or incorrect GSD parameter loading. Additionally, the module’s reliance on precise timing for PROFIBUS token handling makes it sensitive to voltage sags on the backplane supply, which may cause intermittent bus faults (BF LED flashing).

Key design limitations include:

- Single PROFIBUS port (no redundancy without a second CI532V05)

- Limited diagnostic depth—basic BF indication without detailed error logging

- No built-in surge protection on the D-SUB connector

Preventive maintenance recommendations:

- Verify PROFIBUS cable shield continuity and termination resistors annually

- Monitor bus voltage (should be 3–5 V differential) using a protocol analyzer

- Maintain offline backup of GSD files and module configuration in Control Builder M

- Install external PROFIBUS isolators or surge suppressors in high-risk environments

CI532V05 3BSE007297R1 ABB

Lifecycle Status and Migration Strategy

ABB officially discontinued the CI532V05 in 2015, with end-of-support concluded by 2019. No new units are manufactured, and remaining inventory consists of used or refurbished stock with uncertain operational history.

As an interim solution, facilities may:

- Acquire and functionally test one or more spares with matching firmware

- Implement external PROFIBUS repeaters with isolation to reduce electrical stress

- Segment critical devices onto separate fieldbus segments to limit failure impact

For long-term sustainability, ABB recommends migrating to the CI854A (PROFIBUS) or CI871 (PROFINET) communication modules within the modernized AC 800M platform. The CI854A offers direct functional replacement with enhanced diagnostics and better surge resilience, though it requires:

- Updated GSD files in the Control Builder M project

- Potential reassignment of I/O tags due to different module addressing

- Verification of PROFIBUS master parameters (e.g., TTR, min slave interval)

Migration can be executed during planned outages without replacing field devices, preserving existing cabling and slave hardware. This path restores access to factory support, improves network reliability, and aligns the system with current cybersecurity and lifecycle management practices.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: