Description

Key Technical Specifications (For Spare Parts Verification)

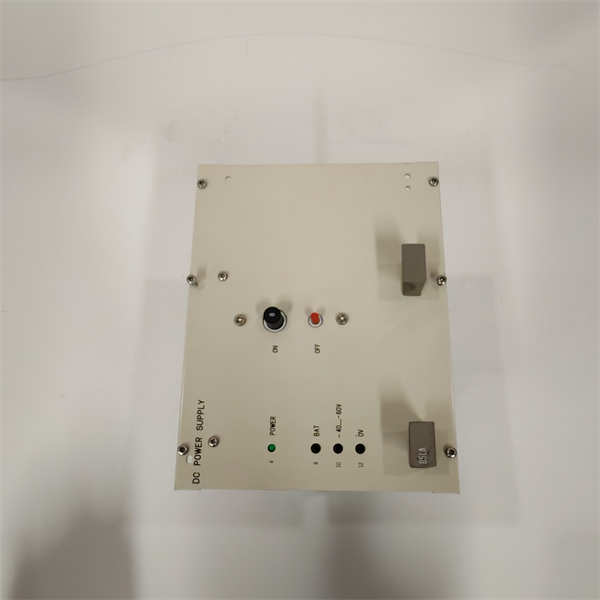

- Product Model: B5LA

- Manufacturer Order Code: HENF327886R0001

- Manufacturer: ABB

- System Platform: AC 800M Controller (part of ABB Ability™ System 800xA)

- Module Type: CPU / Main Processor Unit (commonly labeled PM851 in documentation)

- Processor: 32-bit RISC architecture

- Memory: Integrated application memory (typically 4 MB RAM, non-expandable)

- Communication Interfaces: Dual CAN buses for I/O modules, serial port (RS-232) for service, optional Ethernet via separate communication module (e.g., CI854)

- Redundancy Support: Optional (requires redundant CPU pair and synchronization link)

- Programming Environment: Control Builder M (within System 800xA Engineering)

- Mounting: DIN rail-mounted in AC 800M chassis with dedicated power and backplane

System Role and Downtime Impact

The B5LA (PM851) is the central execution engine in legacy AC 800M systems, responsible for running all control strategies—from boiler combustion control to water treatment sequencing. It coordinates data exchange with local and remote I/O modules, executes safety interlocks, and interfaces with the System 800xA operator environment. In non-redundant configurations—which are common in auxiliary or older installations—a single CPU failure causes total loss of automatic control, forcing operators into manual mode or triggering a full process shutdown. Even in redundant setups, replacement requires careful synchronization, firmware matching, and application download verification. Recovery time is heavily dependent on spare part availability and access to legacy Control Builder M licenses, both of which are increasingly constrained.

Reliability Analysis and Common Failure Modes

Deployed widely from the early 2000s through the late 2010s, the B5LA is now susceptible to age-related degradation. The most common failure modes include:

- Onboard flash memory wear-out, leading to application corruption or inability to retain program after power cycle.

- CAN bus driver IC failure, causing loss of communication with I/O modules—often manifesting as “I/O not responding” alarms across multiple racks.

- Internal power regulation instability, resulting in spontaneous resets or failure to boot, especially under high ambient temperatures.

- Battery-backed RAM issues (if equipped), causing loss of retentive variables or clock settings.

- Connector or solder joint fatigue due to thermal cycling, creating intermittent faults that are difficult to reproduce during bench testing.

A critical vulnerability is the lack of onboard Ethernet in base models; reliance on external communication modules adds another point of failure for host connectivity. Preventive measures include regular backup of application code, monitoring of CPU load and scan time trends, inspection of cooling airflow, and verification of firmware consistency across spares.

ABB B5LA HENF327886R0001

Lifecycle Status and Migration Strategy

ABB has discontinued the B5LA (PM851) in favor of higher-performance CPUs such as the PM856, PM858, and the newer AC 900F platform. No new units are available through official channels. Continued use carries significant operational and compliance risk: untested surplus may fail under load, firmware mismatches can prevent application downloads, and cybersecurity gaps exist due to lack of modern secure boot or encrypted communication features.

Short-term mitigation includes:

- Sourcing only from certified vendors providing full functional test reports, including CAN bus communication validation and application load testing

- Maintaining a matched spare (same firmware and hardware revision) in climate-controlled storage

- Performing regular full-system backups using Control Builder M

Long-term, the recommended path is migration to PM856 or PM858 CPU modules, which offer:

- Higher processing speed and larger memory capacity

- Integrated Ethernet ports (reducing dependency on external comms modules)

- Enhanced cybersecurity features and support for modern OPC UA

- Full compatibility with current System 800xA versions

Migration typically requires hardware replacement, recompilation of the control application, and re-commissioning—but restores access to ABB support, improves system resilience, and ensures alignment with evolving industrial security standards for critical infrastructure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: