Description

Key Technical Specifications (for Spare Verification)

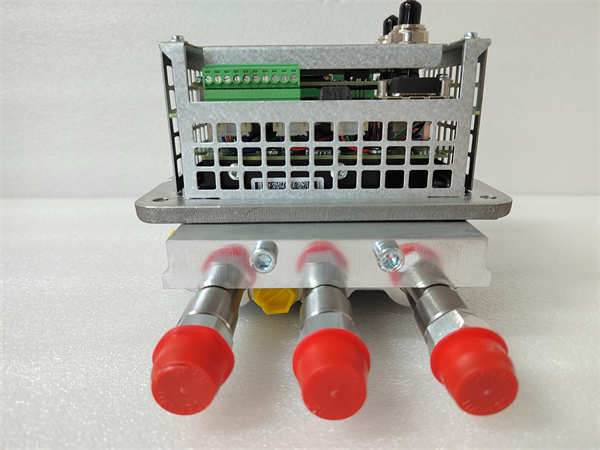

- Product Model: ACU-01B

- Manufacturer: ABB

- Part Number: 3HNA024871-001

- Revision: 03

- System Family: ABB IRC5 robot controller (used with IRB 6400, IRB 6600, IRB 7600 series, etc.)

- Function: Provides 8 analog outputs (±10 V) and 8 analog inputs (±10 V) for peripheral device control

- Communication Interface: Proprietary high-speed serial link to IRC5 Main Computer (MC) board

- Power Supply: +5 V and ±12 V from IRC5 backplane

- Mounting Location: Installed in the IRC5 drive module chassis (typically alongside AXD/AXS boards)

- Diagnostic Indicators: Two LEDs – “RUN” (green) and “ERROR” (red)

- Connector Type: 50-pin DIN 41612 backplane connector; field wiring via removable terminal blocks

System Role and Downtime Impact

The ACU-01B is a critical interface module within the ABB IRC5 robot controller architecture. It enables the robot system to communicate with analog-based peripheral equipment such as proportional valves, analog position sensors, force/torque transducers, or coordinated external axes. Without a functional ACU-01B, the robot may lose synchronization with tooling or workpiece handling systems, leading to positioning errors, cycle interruption, or complete cell stoppage. In automotive body shops or high-mix assembly lines where multiple robots operate in takt time, failure of this module can cascade into line-wide downtime. Given that many IRC5 systems remain in service beyond their intended lifecycle—especially in heavy industry—the unavailability of this module poses a direct operational risk.

Reliability Analysis and Common Failure Modes

Although designed for industrial robustness, the ACU-01B is now commonly affected by age-related degradation. The most frequent failure mode is drift or saturation in analog output channels due to aging operational amplifiers and reference voltage components, resulting in incorrect actuator positioning. Input channels may become noisy or unresponsive from contamination on terminal blocks or ESD damage to front-end protection circuits. The module’s reliance on stable ±12 V power makes it vulnerable to ripple or voltage sag from aging IRC5 power supplies, which can cause intermittent communication faults with the Main Computer. Additionally, repeated thermal cycling over 10–15 years can lead to micro-cracks in solder joints around high-power components.

Recommended preventive actions include:

- Periodically verifying analog output accuracy using a calibrated multimeter during scheduled maintenance

- Inspecting and cleaning terminal blocks to prevent contact resistance buildup

- Monitoring IRC5 system logs for “ACU Communication Fault” or “Analog I/O Error” messages

- Ensuring cabinet cooling is adequate to minimize thermal stress on internal electronics

ACU-01B 3HNA024871-001 03 ABB

Lifecycle Status and Migration Strategy

ABB has officially discontinued the ACU-01B as part of the broader phase-out of the IRC5 platform. No new units are available through distribution channels, and technical support is restricted to third-party specialists. Continuing to operate with this module carries significant risk: verified spares are scarce, and untested units from open markets often fail shortly after installation due to latent defects.

In the short term, facilities can mitigate risk by procuring pre-tested, functionally verified units from certified vendors who perform full I/O calibration and burn-in testing. Some organizations opt for board-level repair, though component obsolescence limits long-term viability.

For a sustainable solution, ABB recommends migrating to the OmniCore controller platform, which replaces the entire IRC5 architecture. This transition involves:

- Replacing the IRC5 cabinet with an OmniCore controller

- Rewiring field devices to match OmniCore’s I/O topology (which uses EtherCAT-based distributed I/O instead of centralized analog cards)

- Recompiling robot programs in RobotStudio (though path data can often be imported)

While this requires capital investment, it restores access to cybersecurity updates, remote diagnostics, and modern integration capabilities (e.g., OPC UA, MQTT), ensuring compliance with current industrial standards and extending the robot cell’s operational life.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: