Description

Key Technical Specifications (For Spare Parts Verification)

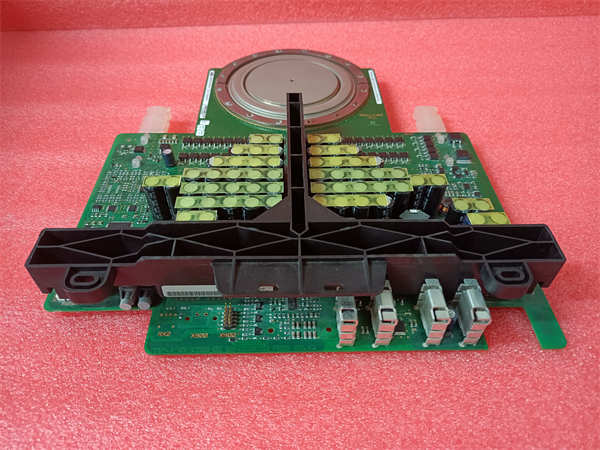

- Model Number: GVC736BE101

- Alternate Part Numbers: 5SHY5055L0002, 3BHE019719R0101

- Manufacturer: ABB

- System Family: ACS1000 / ACS6000 Medium-Voltage Adjustable Speed Drives

- Compatible Power Semiconductors: IGCT modules (e.g., 5SHX series, typically 4.5 kV class)

- Function: IGCT gate pulse generation, desaturation detection, overcurrent protection, and status feedback to the drive controller

- Power Supply Input: ±15 VDC and +24 VDC from auxiliary supply unit

- Isolation: Reinforced galvanic isolation between control and power circuits (typically >10 kV)

- Communication Interface: Fiber-optic link to main control board (e.g., VCU or DDCS network)

- Diagnostic Outputs: Fault signals (e.g., “IGCT Fail,” “Undervoltage”) via opto-coupled digital lines

- Form Factor: PCB module mounted directly onto IGCT heat sink assembly

- Operating Environment: Designed for high EMI, high dv/dt industrial drive cabinets

System Role and Downtime Impact

The GVC736BE101 is a mission-critical subcomponent within ABB’s medium-voltage drive power stacks, commonly used in mining conveyors, ship propulsion, water pumps, and industrial compressors. It acts as the interface between the low-voltage control system and the high-power IGCT switches that modulate motor voltage. Each GVC736BE101 controls one IGCT, and a single drive may contain dozens of these boards.

If this gate driver fails—due to internal component degradation, fiber-link disruption, or power supply instability—it can cause:

- Immediate inhibition of IGCT firing, leading to drive trip and process stoppage

- Uncontrolled turn-off of the IGCT, resulting in voltage spikes that damage the semiconductor or DC bus capacitors

- False fault reporting that masks the real issue, prolonging troubleshooting time

Given that ACS1000/6000 drives often control multi-megawatt loads, a GVC736BE101 failure can result in unplanned downtime costing tens of thousands of dollars per hour. In redundant or multi-drive systems, it may force load shedding or manual bypass operation with reduced efficiency.

Reliability Analysis and Common Failure Modes

Despite robust design, the GVC736BE101 operates under extreme electrical stress and is prone to age-related failures:

- Optocoupler or fiber transmitter degradation: Over time, light output diminishes, causing timing jitter or complete loss of gate pulse transmission.

- High-voltage capacitor aging: Onboard ceramic or film capacitors in the gate drive circuit lose capacitance, reducing peak current delivery and slowing IGCT turn-on—increasing switching losses and thermal stress.

- PCB delamination near high-dv/dt traces: Repeated thermal cycling cracks the substrate around gate output paths, creating intermittent shorts or opens.

- Power supply regulator failure: The onboard DC/DC converters that generate isolated gate voltages can fail due to input ripple or overheating, disabling the entire board.

Key design vulnerabilities include exposure to reflected voltage transients from the IGCT and dependence on clean, stable auxiliary power. For preventive maintenance, technicians should:

- Perform annual insulation resistance tests on fiber links

- Monitor drive event logs for “Gate Driver Fault” or “IGCT Desat” warnings

- Inspect boards for discoloration, burnt smell, or swollen components during outages

- Ensure cabinet cooling is adequate to keep ambient temperature below 45°C

5SHY5055L0002 3BHE019719R0101 GVC736BE101 ABB

Lifecycle Status and Migration Strategy

ABB has discontinued the GVC736BE101 as part of the broader phase-out of the ACS1000 platform, with focus shifted to the ACS580MV, ACS880 MV, and Ability™-enabled drives. No new units are produced, and factory repair services are no longer offered. Continuing to operate legacy drives with this board carries substantial risk: no access to genuine spares, increasing mean time to repair (MTTR), and potential cascading damage to expensive IGCT modules.

As an interim solution, facilities may:

- Source boards from certified third-party rebuilders with full functional and hi-pot testing

- Implement drive-level redundancy (e.g., dual-drive master/follower) to tolerate single-board faults

- Stockpile tested spares while availability lasts

For long-term sustainability, ABB recommends migrating to modern ACS880 MV drives with modular power cells and advanced diagnostics. This upgrade path involves:

- Replacing the entire power stack and control system

- Retaining existing motor and transformer (subject to compatibility review)

- Leveraging ABB Ability™ for remote monitoring and predictive maintenance

Given its direct role in semiconductor switching integrity, the obsolescence of the GVC736BE101 represents a high-severity operational risk. Proactive management—through strategic sparing or planned drive modernization—is essential to ensure continuity in critical industrial processes.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: