Description

Key Technical Specifications (For Spare Part Verification)

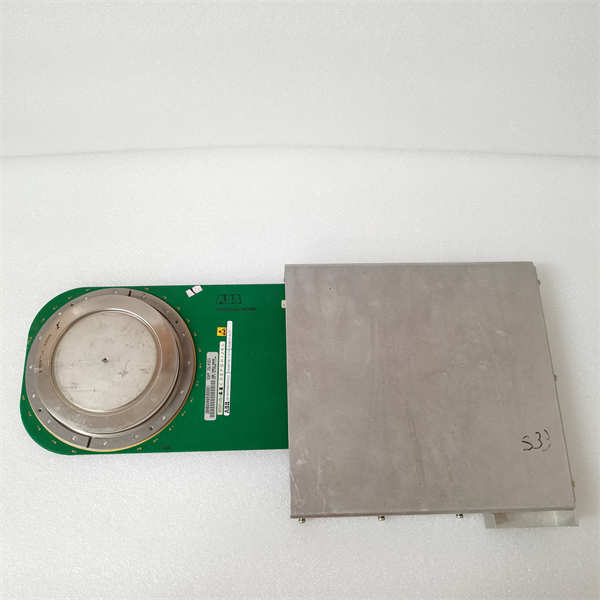

- Product Model: 5SHY35L4503

- ABB Part Numbers: 3BHB004693R0001 (anode-side IGCT), 3BHB004692R0002 (cathode-side IGCT), 5SXE01-0127 (gate driver PCB)

- Manufacturer: ABB

- Application System: ACS1000, ACS6000, and other IGCT-based medium-voltage drives

- Voltage Class: 4.5 kV (blocking voltage)

- Current Rating: 3,500 A (nominal RMS)

- Switching Frequency: Typically < 200 Hz (line-commutated operation)

- Cooling: Water-cooled heatsink interface with integrated temperature sensors

- Gate Interface: Requires matched 5SXE01-0127 driver board for precise turn-on/off timing

- Mounting: Bolted press-pack assembly with calibrated torque and alignment fixtures

- Diagnostics: Integrated thermistor and gate health monitoring via drive controller

-

ABB 5SHY35L4503 3BHB004693R0001 3BHB004692R0002 5SXE01-0127

System Role and Downtime Impact

These components constitute a phase leg of the three-phase inverter in ABB’s high-power IGCT-based drives, commonly deployed in oil & gas, mining, cement, and water infrastructure. The 5SHY35L4503 IGCTs—paired as anode/cathode units—and their dedicated gate driver board (5SXE01-0127) enable efficient, high-torque motor control at medium voltage (typically 3.3–6.6 kV).

Failure of any single IGCT or its driver results in unbalanced output, overcurrent fault, and automatic drive trip. Unlike modular low-voltage IGBT systems, IGCT stacks are not hot-swappable and require full power-down, coolant isolation, and precision mechanical reassembly. Without verified spares, recovery can take 5–10 days or longer, especially if original torque specs or gate calibration data are missing. In continuous-process industries, this equates to hundreds of thousands of dollars in lost production per day.

Reliability Analysis and Common Failure Modes

Despite industrial-grade design, these components face predictable aging challenges after 10–20 years of service:

Gate driver boards (5SXE01-0127) suffer from capacitor drying and optocoupler degradation, leading to delayed or failed triggering—often causing “cross-conduction” and catastrophic IGCT short-circuit. The IGCTs themselves (5SHY35L4503) are vulnerable to thermal fatigue at the ceramic-to-metal interface due to repeated heating/cooling cycles, resulting in internal delamination or increased on-state voltage drop. Water-cooling channel corrosion or seal leaks can introduce moisture, accelerating electrical tracking. Additionally, improper handling during past maintenance (e.g., uneven clamping force) creates latent mechanical stress that triggers sudden failure under load.

Preventive actions include:

- Annual infrared thermography of drive cabinets to detect abnormal heating

- Monitoring gate pulse integrity via oscilloscope during scheduled outages

- Verifying coolant conductivity and pH to prevent electrolytic corrosion

- Maintaining calibrated torque wrenches and alignment tools for future replacements

Storing complete phase-leg kits (IGCT pair + driver board) as matched sets

ABB 5SHY35L4503 3BHB004693R0001 3BHB004692R0002 5SXE01-0127

Lifecycle Status and Migration Strategy

ABB ceased production of discrete IGCT modules like the 5SHY35L4503 as it transitioned to integrated power blocks and newer topologies (e.g., IEGT, modular multilevel converters). Hitachi Energy no longer offers new units or factory repairs for these legacy parts. While some third-party specialists offer reconditioning or surrogate drivers, performance and reliability cannot be guaranteed.

Short-term mitigation requires:

- Securing at least one full spare phase-leg assembly (including both IGCTs and 5SXE01-0127 board)

- Performing baseline electrical tests (Vf, gate threshold) on all installed units

- Documenting mechanical assembly procedures with photos and torque logs

Long-term strategy involves drive modernization:

- Replace entire ACS1000/6000 cabinet with current-generation ACS5000 or IEGT-based drives

- Retain existing motor and transformer; reuse medium-voltage cabling where possible

- Benefit from improved efficiency, predictive diagnostics, and cybersecurity compliance

- Reduce footprint and cooling requirements through higher switching frequencies

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: