Description

Key Technical Specifications (For Spare Parts Verification)

- Product Models:

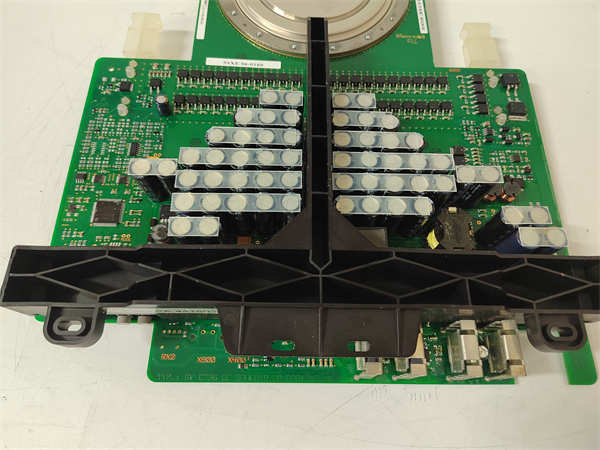

- 5SHY3545L0016 (ABB Part No. 3BHE008552R0101)

- 3BHB019719R0101 (equivalent to GVC736BE101)

- 5SXE06-0160 (ABB Part No. 3BHE009628R0101)

- Manufacturer: ABB

- System Family: ACS1000 Medium-Voltage Adjustable Speed Drive

- Voltage Class: Designed for 3.3 kV, 4.16 kV, or 6.6 kV motor systems

- Power Semiconductor: Integrated Gate-Commutated Thyristor (IGCT) based

- Control Architecture: Distributed gate drive with centralized logic on GVC736BE101

- Communication: Fiber-optic links between control board and gate drivers

- Firmware Dependency: GVC736BE101 requires specific software version alignment with HESG447001 (CPU board)

- Operating Environment: Requires clean, dry, temperature-controlled drive cabinet (<45°C)

- Diagnostic Interfaces: RS-232 service port on GVC736BE101 for DriveWindow diagnostics

System Role and Downtime Impact

These components reside at the heart of the ACS1000 inverter section. The GVC736BE101 generates PWM timing signals, which are transmitted via fiber optics to the 5SXE06-0160 interface modules, which in turn drive the 5SHY3545L0016 gate units that switch the IGCTs. This chain controls the output voltage and frequency to the motor.

Failure of any one component typically results in:

- “Gate Fault,” “Overvoltage,” or “IGCT Desaturation” trip

- Immediate inhibition of inverter operation

- Full stop of driven equipment (e.g., main gas compressor, cooling water pump)

In continuous processes, such unplanned downtime can cost tens of thousands of dollars per hour and may trigger cascading plant-wide disruptions. Because these parts are not hot-swappable and require system re-commissioning after replacement, lead time for spares directly translates to production loss.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, aging ACS1000 electronics exhibit predictable degradation:

- Optocoupler/fiber driver aging: On the 5SHY3545L0016 and 5SXE06-0160, optical transmitters degrade, causing delayed or missing gate pulses—leading to IGCT misfiring and overcurrent faults.

- Electrolytic capacitor drying: Power supply sections on GVC736BE101 lose capacitance over time, resulting in brownouts during transient loads and erratic CPU behavior.

- PCB delamination and trace cracking: Thermal cycling from IGCT switching losses induces micro-fractures near high-current paths, especially on older boards without conformal coating.

- Firmware corruption: Battery-backed SRAM on GVC736BE101 loses configuration if the onboard coin cell (CR2032) is not replaced every 5–7 years.

Design vulnerabilities include sensitivity to EMI from nearby switchgear and dependence on stable 24 VDC auxiliary power. For preventive maintenance, technicians should:

- Replace backup batteries on all control boards during scheduled outages

- Perform annual thermal imaging of gate driver stacks to detect abnormal heating

- Verify fiber-optic link integrity using optical power meters

- Keep firmware backups of GVC736BE101 and associated CPU boards

ABB 5SHY3545L0016 3BHB019719R0101 GVC736BE101 5SXE06-0160

Lifecycle Status and Migration Strategy

ABB officially discontinued the ACS1000 platform over a decade ago, with support redirected to the ACS5000 (IGCT-based) and ACS6000 (IGBT-based) families. None of the listed parts are manufactured today, and ABB no longer provides repair services for them outside rare legacy contracts. Continuing to operate with these components carries significant risk: no access to genuine replacements, increasing likelihood of counterfeit or mismatched firmware versions, and growing difficulty sourcing compatible diagnostic tools (e.g., legacy DriveWindow licenses).

As an interim measure, facilities may:

- Secure tested, matched sets from ABB-certified surplus partners with full operational logs

- Maintain complete spare drive sections (not just individual boards) to minimize commissioning time

- Implement external vibration and temperature monitoring on driven motors to enable graceful degradation planning

For long-term sustainability, ABB recommends migrating to the ACS580MV or ACS6000 platforms. This involves:

- Replacing the entire drive power and control section

- Reusing existing input transformer and motor cabling where feasible

- Re-engineering protection and control logic in the new ABB Ability™ environment

- Retraining maintenance staff on modern drive diagnostics and cybersecurity features

Given their central role in high-power motor control, the obsolescence of these ACS1000 components represents a critical asset risk. A formal risk assessment—and either strategic sparing or inclusion in a capital upgrade plan—is essential to ensure operational continuity and safety.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: