Description

Key Technical Specifications (For Spare Parts Verification)

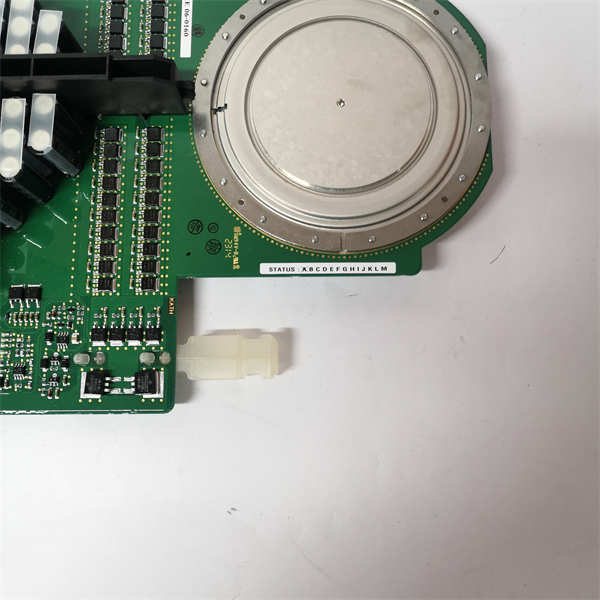

- Product Model: 5SHY3545L0016

- Functional Name: GVC736BE101 IGCT Gate Unit

- Manufacturer: ABB

- System Family: ACS1000 / ACS6000 Medium-Voltage Adjustable Speed Drives (3.3–6.6 kV)

- Power Device Compatibility: Designed for 4500V-class IGCTs (e.g., 5SHX series)

- Control Interface: Receives fiber-optic firing pulses from the drive’s main control board (e.g., NRED or NIOC)

- Power Supply: Derived from auxiliary DC-link voltage (~100 VDC) via internal DC/DC converters

- Isolation: Optical isolation between low-voltage control and high-voltage power sections

- Diagnostic Features: Provides feedback signals (OK, FAULT) to the drive controller via backplane

- Physical Form: Multi-board assembly mounted directly on or near the IGCT stack inside the power cage

- Subcomponents: Includes 3BHB020720R0002 (main gate driver PCB) and 3BHE019719R0101 (signal interface & monitoring board)

System Role and Downtime Impact

The GVC736BE101 (5SHY3545L0016) is a mission-critical component in ABB’s early-generation IGCT-based medium-voltage drives, commonly used to control large motors in mining, oil & gas, and water pumping applications (500 kW to 20+ MW). It translates low-energy optical commands from the drive’s central controller into high-current gate pulses required to switch multi-kilovolt IGCTs. Without functional gate units, the inverter cannot operate—resulting in an immediate “Gate Fault” or “IGCT Fault” and a hard stop of the motor. In continuous-process industries, such a failure can halt entire production lines or critical infrastructure (e.g., pipeline compression or mine hoists), with downtime costs exceeding $50,000 per hour. Due to its integration within the high-voltage section, replacement requires qualified personnel and a full drive shutdown.

Reliability Analysis and Common Failure Modes

Despite robust design, the GVC736BE101 is prone to age-related and stress-induced failures. The most frequent cause is degradation of electrolytic capacitors on the internal DC/DC converter boards (particularly on 3BHB020720R0002), leading to insufficient gate drive voltage and erratic IGCT switching. A second common failure mode is optical receiver degradation, where the fiber-optic input circuit loses sensitivity over time, causing missed firing pulses. Additionally, thermal cycling fatigue at solder joints—exacerbated by poor cabinet cooling—can result in intermittent connections or open circuits.

Design vulnerabilities include limited thermal margin in early revisions and sensitivity to voltage transients on the auxiliary supply. For maintenance teams, key preventive actions include:

- Monitoring drive fault logs for recurring “Gate OK” warnings

- Performing infrared thermography during operation to detect hot spots on gate units

- Replacing gate units proactively during major outages if installed for >10 years

- Ensuring clean, dry, and temperature-controlled drive room environment

ABB 5SHY3545L0016 3BHB020720R0002 3BHE019719R0101 GVC736BE101

Lifecycle Status and Migration Strategy

ABB has discontinued the GVC736BE101 and its subcomponents as part of the phase-out of first-generation IGCT drives. No new units are available from the factory. Repair services are limited to third-party specialists with access to obsolete components, and success is not guaranteed.

As a short-term mitigation, operators may source and test surplus assemblies, but functional validation under high-voltage conditions is essential. ABB’s strategic migration path is to replace the entire drive with the ACS6080 or ACS5080 platform, which uses modern IGBT-based technology, offers higher efficiency, built-in cybersecurity, and long-term lifecycle support. While this requires significant capital investment, it eliminates obsolescence risk and reduces maintenance complexity.

For facilities extending legacy drive life, maintaining a stock of at least two fully tested gate units per drive—along with spare optical cables and mounting hardware—is strongly advised. Partnering with specialized service providers capable of board-level repair and capacitor rework can further extend operational life while planning for eventual system modernization.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: