Description

Key Technical Specifications (For Spare Parts Verification)

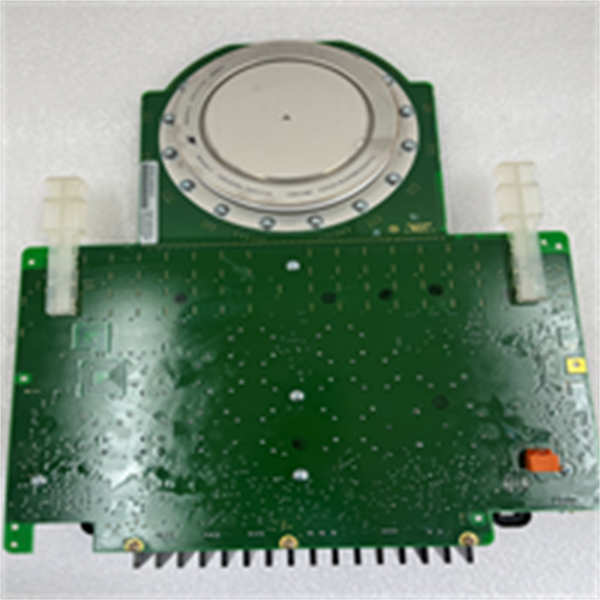

- Product Model: 5SHY3545L0010

- Manufacturer: ABB

- System Family: ACS1000 / ACS6000 medium-voltage adjustable speed drives

- Device Type: IGCT gate drive unit (GDU)

- Compatible Semiconductor: Typically used with 5SHX series IGCTs (e.g., 5SHX1445H0002)

- Supply Voltage: Powered from isolated DC/DC converters within the drive stack (~15–24 VDC logic, higher for gate pulse)

- Output Capability: High di/dt gate current pulses (several amperes) with nanosecond-level timing accuracy

- Isolation: Reinforced galvanic isolation between control and power sections

- Mounting: Directly mounted on IGCT heat sink or phase module

- Connector Type: Multi-pin hermetic or press-fit connector (ABB proprietary)

- Diagnostic Features: May include fiber-optic feedback for gate status (depending on system version)

System Role and Downtime Impact

The 5SHY3545L0010 is a critical interface between the drive’s central control electronics and the high-power IGCT valves in ABB’s medium-voltage drive cabinets. It translates low-voltage PWM signals into precisely timed, high-current gate pulses required to turn IGCTs on and off at switching frequencies up to several hundred hertz. In applications such as mine hoists, ship propulsion, or large compressors, a single GDU failure disables one phase leg of the inverter, triggering a fault lockout and halting the entire drive. Given the high capital intensity of these systems, unplanned downtime can cost tens of thousands of dollars per hour.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, these gate units are sensitive to electrical overstress and thermal fatigue. Common failure modes include:

- Damage to gate driver ICs or MOSFET output stages due to voltage spikes from IGCT turn-off transients

- Degradation of optical isolators or fiber interfaces from prolonged exposure to EMI in high-dV/dt environments

- Cracked solder joints or delamination caused by repeated thermal cycling during drive operation

- Moisture ingress leading to corrosion on PCB traces, especially in humid or outdoor installations

A key vulnerability is the lack of field-replaceable subcomponents—the entire unit is typically sealed and not serviceable at the component level. Additionally, aging of the internal DC/DC converter can reduce gate pulse amplitude over time, causing intermittent misfiring that is difficult to diagnose.

Preventive maintenance should focus on: inspecting for discoloration or burnt smell, verifying secure mechanical mounting (to ensure thermal contact), checking fiber-optic links for bends or contamination, and monitoring drive fault logs for repetitive “gate feedback loss” or “IGCT desaturation” events.

Preventive maintenance should focus on: inspecting for discoloration or burnt smell, verifying secure mechanical mounting (to ensure thermal contact), checking fiber-optic links for bends or contamination, and monitoring drive fault logs for repetitive “gate feedback loss” or “IGCT desaturation” events.

ABB 5SHY3545L0010

Lifecycle Status and Migration Strategy

ABB has officially discontinued the 5SHY3545L0010 as part of the broader phase-out of first-generation IGCT-based ACS1000/6000 platforms. No direct replacement is offered under the same part number. Continued use carries substantial risk: new-old-stock units are scarce, often priced at 3–5× original cost, and may have degraded internal components despite being unused.

Temporary mitigation includes:

Temporary mitigation includes:

- Sourcing tested units from specialized obsolete power electronics brokers

- Implementing rigorous spare inventory management (minimum 2–3 units per critical drive)

- Engaging third-party repair services capable of board-level rework (though success is not guaranteed due to proprietary ASICs)

For long-term sustainability, ABB recommends migrating to newer drive platforms such as the ACS580 MV or Ability™-enabled ACS880 MV, which use more robust IGBT or IGCT modules with integrated or modular gate drivers and enhanced diagnostics. However, such upgrades require full drive cabinet replacement, motor compatibility review, and re-commissioning—typically justified only during major plant modernization. Until then, proactive monitoring and strategic sparing remain essential to manage operational risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: