Description

Technical Specifications (For Spare Parts Verification)

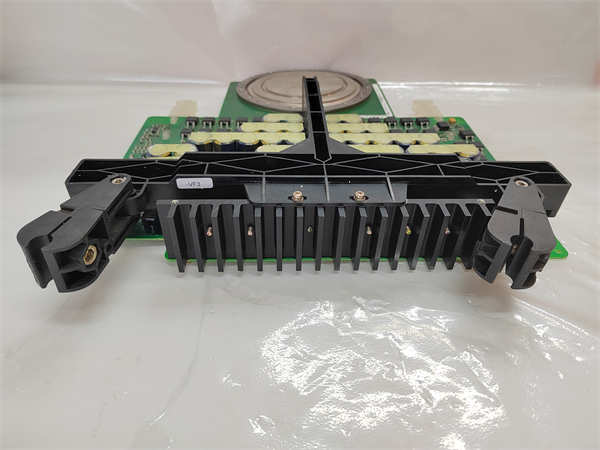

- Primary Module: GVC750BE101 (Gate Valve Controller)

- Gate Driver Unit: 5SHY3545L0010 (ABB Power Electronics product code)

- Interface Board: 3BHB013088R0001 (Fiber-optic I/O interface)

- Auxiliary Board: 3BHE009681R0101 (Power supply and signal conditioning)

- Manufacturer: ABB

- System Family: Legacy ABB FACTS (Flexible AC Transmission Systems) and HVDC Classic platforms

- Compatible Valve Types: 5SHX series IGCT stacks (e.g., 5SHX1445H0002)

- Drive Output: High-current pulses (>20 A peak) with nanosecond-level timing accuracy

- Isolation: Optical fiber communication from controller to valve base electronics

- Operating Voltage: Floating up to several kV relative to ground (per valve position)

- Diagnostic Features: Per-phase fault reporting, gate current monitoring, temperature sensing

System Role and Downtime Impact

The GVC750BE101 system—including the 5SHY3545L0010 gate driver and its support boards—is a core enabler of high-voltage power electronics in transmission-level applications. Deployed in utility-scale SVCs, STATCOMs, and HVDC converter stations, it controls the switching of multi-kilovolt IGCT valves that regulate reactive power or enable DC power transfer. A single faulty gate driver can cause phase imbalance, excessive harmonic generation, or uncontrolled conduction—triggering protective relays and forcing the entire compensator or pole offline. Given these systems often provide grid stability services (e.g., voltage support during faults), unplanned outages can violate grid codes, incur penalties, or destabilize regional networks. Replacement lead times for obsolete units can exceed 6–12 months if not pre-stocked, making spares strategy critical.

Reliability Analysis and Common Failure Modes

These modules operate under extreme electrical and thermal stress, leading to predictable wear mechanisms:

- Gate driver capacitor degradation: High-voltage ceramic and film capacitors in the pulse-forming network lose capacitance over time, reducing drive energy and causing delayed or failed turn-on.

- Opto-coupler/fiber interface aging: Signal delay increases in optical transmitters/receivers, compromising synchronization across phases.

- PCB delamination and trace corrosion: Thermal cycling in valve halls (often unconditioned) causes micro-cracks in high-current paths, especially near mounting hardware.

- Power supply regulator drift: Onboard DC-DC converters (on 3BHE009681R0101) exhibit output voltage shift, affecting logic thresholds and diagnostic accuracy.

A key vulnerability is the lack of real-time health monitoring in early GVC750 firmware—failures are often detected only after a misfire event. As preventive maintenance, operators should:

- Perform periodic gate pulse waveform capture using isolated oscilloscopes to verify rise time and amplitude

- Monitor valve conduction patterns via harmonic spectrum analysis

- Inspect fiber connectors for dust, scratches, or misalignment during outages

- Store spare units in climate-controlled, ESD-safe environments to prevent latent damage

5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 ABB

Lifecycle Status and Migration Strategy

ABB has discontinued the GVC750 platform in favor of the GVC751 and GVC752 series, which feature improved diagnostics, higher noise immunity, and compatibility with modern MACH2 or MicroSCADA control systems. The original 5SHY3545L0010 drivers and GVC750BE101 controllers are no longer manufactured, and official repair services have been phased out.

As an interim measure, asset owners can:

- Secure tested spares from vendors who validate performance on IGCT test benches with actual valve loads

- Implement “rotating reserve” practices—periodically powering spares to prevent capacitor stagnation

- Avoid mixing revisions (e.g., R0101 vs R0201) without thorough compatibility review

Full migration requires replacement of the entire valve base electronics, re-commissioning of firing angle calibration, and potential updates to the station control interface. For utilities extending legacy FACTS/HVDC life, maintaining a strategic inventory of fully validated GVC750 spares—coupled with enhanced condition monitoring—is the most pragmatic approach to mitigate grid reliability risk until capital upgrade programs are executed.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: