Description

Technical Specifications (For Spare Parts Verification)

- Product Models:

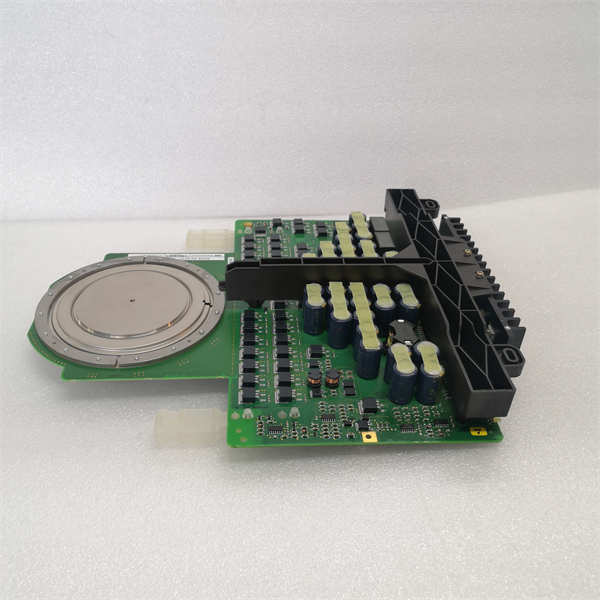

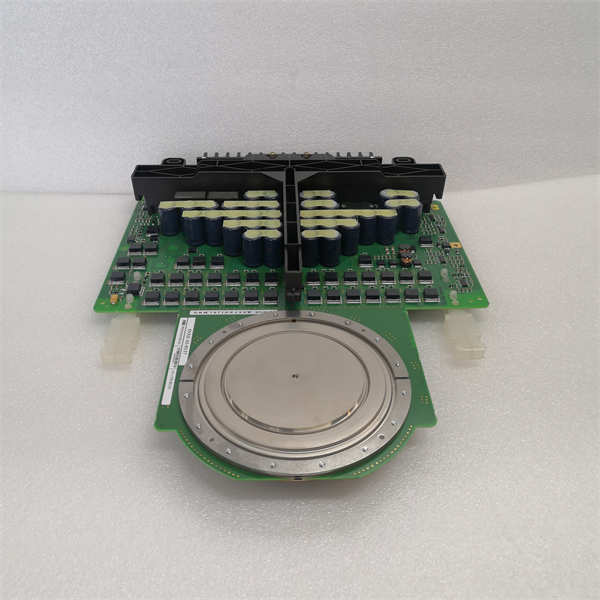

- 5SHY3545L0009: Thyristor module, 3.5 kV repetitive peak off-state voltage, 4.5 kA average current

- 3BHB013085R0001: Electronic gate pulse amplifier board for thyristor triggering

- 3BHE009681R0101: Aluminum heat sink with mounting hardware for thyristor stack

- GVC750BE101: Metal enclosure/chassis for GVC750 valve electronics, includes EMI shielding and fiber-optic feedthroughs

- Manufacturer: ABB

- System Family: GVC750 Valve Control Platform (used in HVDC Classic and SVC installations)

- Voltage Class: Medium to high power (typically 100–800 kV DC systems)

- Cooling Method: Air- or water-cooled (depends on overall valve design)

- Interface: Optical fiber for gate signals, copper busbars for power, RS-485 or CAN for diagnostics

- Environmental Rating: Designed for indoor HVDC valve halls (temperature 0–40°C, humidity <80% non-condensing)

- Certification: IEC 60700, IEEE Std 1031, CIGRE compliance

System Role and Downtime Impact

These components reside within the converter valve hall of an HVDC or SVC installation. The 5SHY3545L0009 thyristor is the primary power semiconductor that switches multi-kiloampere currents. The 3BHB013085R0001 gate board ensures precise, synchronized firing. The heat sink (3BHE009681R0101) maintains thermal stability, while the GVC750BE101 chassis houses control electronics and provides EMI isolation.

If any of these fails during operation, the affected 12-pulse bridge may trip, reducing transmission capacity by 50% (in bipolar HVDC) or causing reactive power imbalance in an SVC. In weak grids, this can trigger cascading voltage instability. Forced outages for replacement require de-energizing the entire pole, draining coolant (if water-cooled), and performing high-voltage grounding—procedures that take days to weeks. Given that HVDC links often carry critical interconnect power (e.g., cross-border or offshore wind export), such events carry significant economic and reliability consequences.

Reliability Analysis and Common Failure Modes

Despite robust design, these components operate under extreme electrical and thermal stress:

Common failure modes include thyristor degradation due to repeated overcurrent events (e.g., from AC faults), leading to increased leakage current or turn-on delay. Gate boards (3BHB013085R0001) often fail due to optocoupler aging or voltage transients on auxiliary supplies, causing misfiring or no-firing conditions. Heat sinks can develop coolant leaks (in water-cooled variants) or thermal paste dry-out, resulting in localized overheating.

A key vulnerability is the dependency on precise optical timing. Dust accumulation on fiber connectors or aging LEDs in gate drivers can introduce nanosecond-level delays, disrupting valve commutation. Additionally, corrosion on aluminum heat sinks in humid environments reduces thermal conductivity over time.

Preventive maintenance should include:

- Annual infrared thermography of valve stacks during operation

- Offline testing of thyristor VBO/IDRM parameters during outages

- Inspection of fiber-optic connectors for contamination or micro-bends

- Verification of gate board output pulses using a high-voltage isolated oscilloscope

ABB 5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101

Lifecycle Status and Migration Strategy

ABB (now Hitachi Energy) no longer offers these parts for new projects. However, under its Long-Term Service Agreement (LTSA) program, they remain available for existing HVDC/SVC stations—but only through formal service channels, with lead times often exceeding six months and costs rising steadily.

Continued use is acceptable for well-maintained assets with remaining economic life, but reliance on single-source spares poses strategic risk. As a temporary measure, operators may:

- Stock critical spares during planned outages

- Partner with specialized rebuilders for board-level repair (with OEM-equivalent components)

- Implement enhanced monitoring (e.g., partial discharge sensors) to predict failures

For long-term sustainability, the recommended path is valve modernization—replacing entire thyristor modules and control electronics with current-generation equivalents (e.g., GVC800 platform). This preserves the existing transformer and civil works while upgrading reliability, diagnostics, and cybersecurity. Full migration to VSC-HVDC is typically reserved for new corridors due to cost, but hybrid retrofits are emerging for select applications. Any upgrade requires detailed arc-flash studies, protection coordination updates, and grid-code re-certification.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: