Description

Key Technical Specifications (For Spare Part Verification)

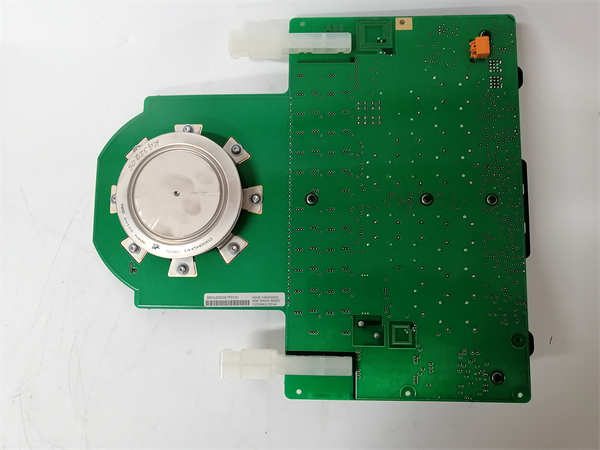

- Product Model: 5SHX1445H0002

- Alternate Label: 3BHL000387P0101

- Manufacturer: ABB

- System Compatibility: ABB AC 800M controller family (used in 800xA DCS)

- Processor Type: 32-bit RISC CPU

- Memory: Integrated program and data memory (non-volatile backup via battery)

- Communication Interfaces: Dual redundant Profibus DP or optional Ethernet (depending on base configuration)

- Redundancy Support: Yes – supports hot-standby CPU redundancy with synchronization link

- Mounting: DIN-rail mounted in AC 800M rail chassis

- Diagnostic Indicators: LEDs for RUN, STOP, I/O status, redundancy state, and battery warning

- Firmware Dependency: Tied to specific versions of Control Builder M engineering tool

System Role and Downtime Impact

The 5SHX1445H0002 serves as the primary logic engine in an AC 800M controller station within ABB’s 800xA system. It executes control programs, manages communication with remote I/O (e.g., CI854, AI810), and interfaces with operator stations, historians, and other controllers. In redundant configurations, it synchronizes application states with its standby counterpart to ensure seamless failover. If this module fails—especially in a non-redundant setup—the entire control station becomes inoperative. This leads to loss of all analog and digital control loops, forcing safety systems into fallback modes or triggering emergency shutdowns. In continuous-process industries such as power generation, oil & gas, or chemicals, this can result in significant production losses, regulatory reporting events, or safety incidents.

Reliability Analysis and Common Failure Modes

Although engineered for industrial environments, the 5SHX1445H0002 exhibits age-related vulnerabilities common to early-2000s embedded controllers. The most frequent failure mode is battery-backed SRAM corruption due to exhausted or leaking lithium batteries, leading to program loss after power cycles. Flash memory wear-out from repeated firmware updates or power interruptions can also render the module unbootable. Additionally, power supply regulator degradation on the internal DC-DC converters may cause intermittent resets or communication dropouts.

A key design weakness is its reliance on proprietary firmware images; if the original project archive is lost, restoring a replacement unit becomes extremely difficult. Units exposed to high ambient temperatures show accelerated capacitor aging near the power input stage. Corrosion on the rear connector pins—especially in humid coastal plants—can disrupt backplane communication with I/O modules.

Recommended preventive actions include:

- Replacing the onboard backup battery every 3–5 years during scheduled outages

- Maintaining up-to-date, version-controlled archives of the Control Builder M project

- Verifying redundancy switchover behavior annually using forced failover tests

- Inspecting module connectors and chassis grounding for signs of oxidation

ABB 5SHX1445H0002 3BHL000387P0101

Lifecycle Status and Migration Strategy

ABB has formally obsoleted the 5SHX1445H0002 as part of its AC 800M product lifecycle management. It is no longer manufactured, and official repair or technical support is unavailable. Continued operation increases exposure to extended downtime due to spare scarcity and declining expertise among service providers.

Short-term risk mitigation includes:

- Securing multiple tested spares with matching firmware and hardware revisions

- Validating full station restore procedures using a test rack and archived project

- Documenting I/O mapping, network addresses, and redundancy cabling

For long-term sustainability, ABB recommends migration to the AC 800M PM866A or PM866AK controller modules. These successors offer:

- Full mechanical and electrical compatibility with existing AC 800M rails and I/O

- Enhanced processing power and memory capacity

- Improved diagnostics and cybersecurity features

- Ongoing firmware and software support via Control Builder M

Migration typically requires re-downloading the existing application (if compatible) or performing a controlled re-engineering effort. For facilities planning broader modernization, integration with ABB’s System 800xA V6+ or Ability™ Genix platforms enables cloud connectivity, advanced analytics, and secure remote access—while preserving core control logic. A phased, controller-by-controller approach minimizes operational disruption and aligns capital expenditure with asset risk profiles.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: