Description

Technical Specifications (For Spare Parts Verification)

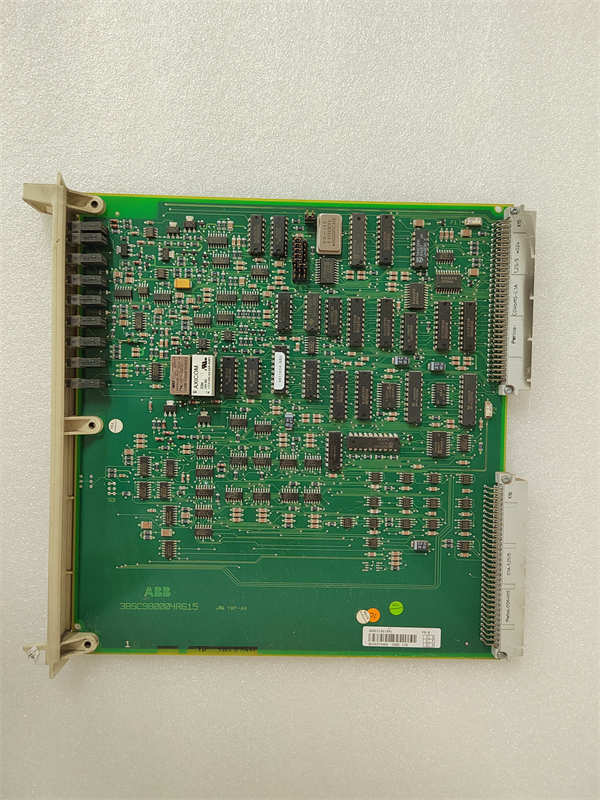

- Product Model: DSBC176

- Manufacturer: ABB

- Order Code: 3BSE019216R1

- System Platform: Advant Controller 450 (AC 450), MasterPiece 300

- Communication Protocol: Proprietary MB300 fieldbus (serial, token-passing)

- Data Rate: 187.5 kbps (typical for MB300 network)

- Max Remote Stations: Supports up to 15 remote I/O racks per segment

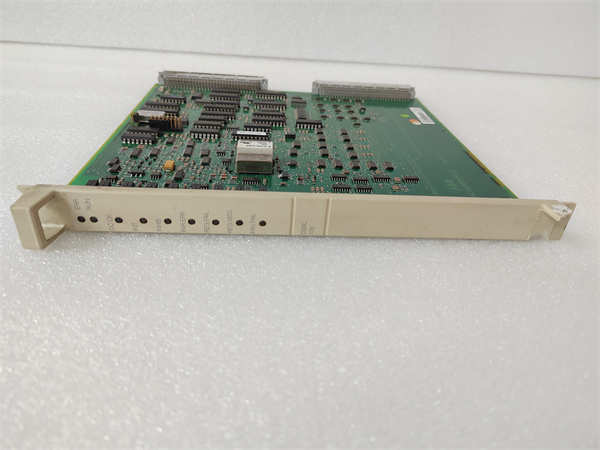

- Backplane Interface: Mounts in CI450 or CI470 I/O chassis, connects to local I/O modules via internal bus

- Power Requirement: Supplied via backplane (+5 VDC, ±12 VDC from rack power supply)

- Diagnostic Indicators: LEDs for power, bus activity, and fault status

- Operating Temperature: 0°C to +60°C

- Physical Interface: DB9 or terminal block for fieldbus cabling (depending on installation)

System Role and Downtime Impact

The DSBC176 serves as the communication gateway between the central AC 450 CPU and a remote I/O station. It resides in the remote rack and handles all data exchange over the MB300 fieldbus. If this module fails, the entire remote I/O station becomes unreachable—disabling dozens or even hundreds of field signals (e.g., motor starts, valve positions, temperature alarms). In a power plant boiler application, for instance, loss of a remote coal feeder or flame scanner rack could force a derate or full unit trip. Because the AC 450 lacks modern redundancy at the bus coupler level (unlike later AC 800M systems with dual Profibus), a single DSBC176 failure directly compromises process availability. Recovery typically requires physical replacement during a forced outage, as hot-swap is not supported.

Reliability Analysis and Common Failure Modes

After decades of service in electrically noisy industrial environments, the DSBC176 exhibits predictable aging patterns:

- RS-485 transceiver IC failure due to repeated voltage surges or ground loops on the MB300 cable, leading to bus communication timeouts.

- Degradation of onboard electrolytic capacitors, causing unstable internal power rails and intermittent resets.

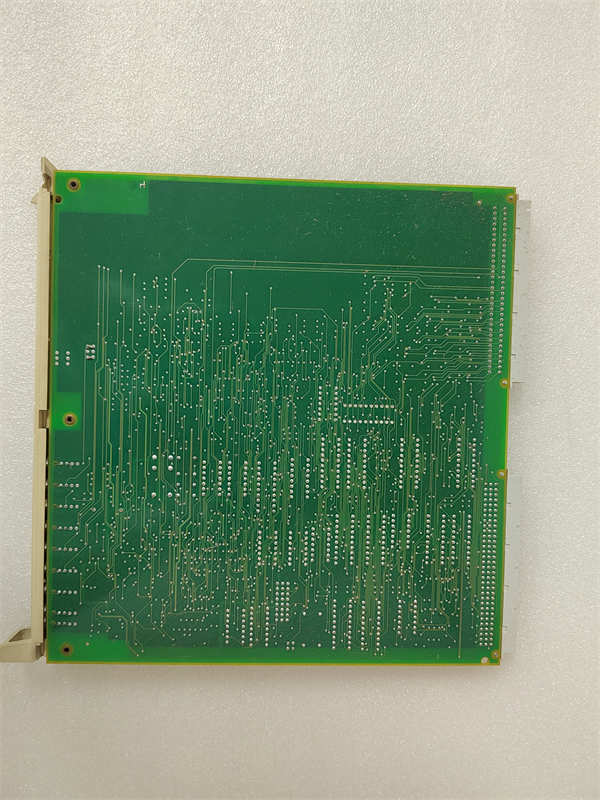

- Corrosion or oxidation on the backplane edge connector, resulting in poor contact and cyclic rack dropouts.

- Firmware corruption from power glitches, especially in sites without UPS-backed control power.

A key vulnerability is the lack of redundant communication paths—each remote rack relies on a single DSBC176. Additionally, the module offers minimal self-diagnostics; the CPU may only report “I/O Rack Not Responding,” requiring manual troubleshooting to isolate the fault.

Preventive maintenance recommendations include:

- Inspecting MB300 cabling for proper shielding, termination, and grounding integrity.

- Measuring bus signal quality with an oscilloscope during outages (checking for ringing, attenuation).

- Verifying stable auxiliary power at the remote rack (ripple and voltage sag under load).

- Keeping a known-good spare powered periodically to prevent capacitor degradation in storage.

DSBC176 3BSE019216R1 ABB

Lifecycle Status and Migration Strategy

ABB ceased production and support for the DSBC176 and the entire AC 450 platform many years ago. Continued use presents escalating risks: spare parts are scarce, counterfeit units circulate in secondary markets, and technical expertise is dwindling.

As an interim measure, operators should:

- Functionally test all existing spares using a bench-configured AC 450 rack.

- Implement network monitoring to detect early signs of bus instability (e.g., rising CRC errors).

- Document exact cabling topology and node addresses to accelerate recovery.

For long-term reliability, ABB’s recommended path is migration to the AC 800M platform within System 800xA. This involves replacing the AC 450 CPU, all I/O modules, and fieldbus infrastructure with modern equivalents (e.g., CI854A for Profibus DP or integrated Ethernet I/O). The new architecture supports redundant communication, advanced diagnostics, and seamless integration with enterprise systems. While requiring re-engineering of control logic and I/O wiring, this upgrade eliminates obsolescence risk and aligns the facility with current cybersecurity and operational standards. Organizations with critical assets should prioritize this transition in their capital planning cycle.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: