Description

Key Technical Specifications (For Spare Part Verification)

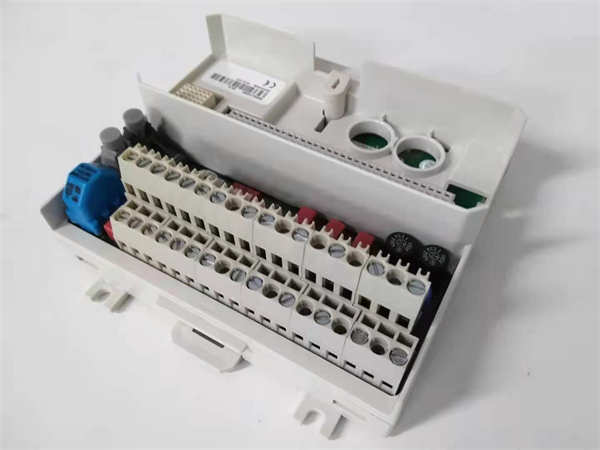

- Product Model: NBIO-21CU

- Manufacturer: ABB

- System Family: AC 800M (part of System 800xA architecture)

- Function: Local I/O baseplate communication interface

- Compatible CPUs: PM860, PM861, PM864, PM865 (AC 800M series)

- I/O Capacity: Supports up to 8 local I/O modules per baseplate

- Communication Bus: Proprietary high-speed parallel backplane bus

- Power Consumption: ~2 W (supplied via backplane)

- Mounting: Snap-in DIN rail baseplate (e.g., BRC01, BRC02)

- Diagnostic Indicators: LEDs for RUN, ERROR, and I/O COMM status

- Redundancy Support: Not supported in NBIO-21CU (non-redundant variant; redundant version is NBIO-21C)

System Role and Downtime Impact

The NBIO-21CU is a foundational component in non-redundant AC 800M control stations, commonly used in smaller process skids, auxiliary systems, or legacy retrofits. It enables the CPU to directly address and cyclically update local I/O modules—such as analog inputs (AI810), digital outputs (DO810), or communication adapters—mounted on the same baseplate. Without a functional NBIO-21CU, the CPU cannot communicate with any local I/O, resulting in loss of sensor feedback, actuator control, and alarm generation. In applications like boiler controls, pump sequencing, or environmental monitoring, this failure typically forces the system into a safe shutdown state or manual override mode, halting automated operation until the module is replaced.

Reliability Analysis and Common Failure Modes

Although solid-state with no moving parts, the NBIO-21CU is susceptible to long-term electrical and thermal stress. Common failure modes include:

- Backplane connector fatigue: Repeated thermal expansion/contraction causes micro-cracks in solder joints, leading to intermittent communication.

- ASIC or FPGA firmware corruption: Rare but possible after power anomalies, causing the module to hang during initialization.

- Power rail instability: Degraded internal voltage regulators result in undervoltage conditions that disrupt I/O polling.

- LED or status circuit failure: Masks true operational state, delaying fault identification during troubleshooting.

A key limitation is the absence of detailed diagnostics—only basic LED indicators are available, with no error logging or performance metrics accessible via System 800xA. Preventive maintenance should include:

- Inspecting baseplate seating and ensuring firm mechanical retention

- Verifying stable +5 VDC and ±15 VDC rails from the PPD115 power supply under load

- Monitoring CPU I/O scan time trends for early signs of communication degradation

- Keeping spare units powered periodically to prevent capacitor aging in storage

ABB 3BSE017427R1 NBIO-21CU

Lifecycle Status and Migration Strategy

ABB has officially discontinued the NBIO-21CU as part of its transition toward higher-performance and cyber-resilient AC 800M hardware. It is no longer available through official channels, and technical support for troubleshooting is extremely limited. Continued reliance introduces significant risk, particularly in unattended or safety-related applications.

Interim measures include:

- Securing tested spares from decommissioned systems with verified operational logs

- Avoiding unnecessary power cycling to reduce thermal stress

- Implementing external watchdog logic to detect I/O communication loss

For long-term viability, ABB’s recommended path is migration to current-generation baseplate interfaces such as the NBIO-22C, which offers enhanced diagnostics, better thermal design, and extended lifecycle support. This upgrade is typically compatible with existing baseplates and I/O modules but requires validation in the System 800xA project environment. In broader modernization efforts, transitioning to the AC 800M High Performance platform (with PM866A CPUs and NBIX-xx baseplates) provides future-proofing through improved cybersecurity, remote access, and at least 10+ years of product availability. Early planning—including spare audits and failure impact assessments—is essential to avoid unplanned outages.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: