Description

Key Technical Specifications (For Spare Part Verification)

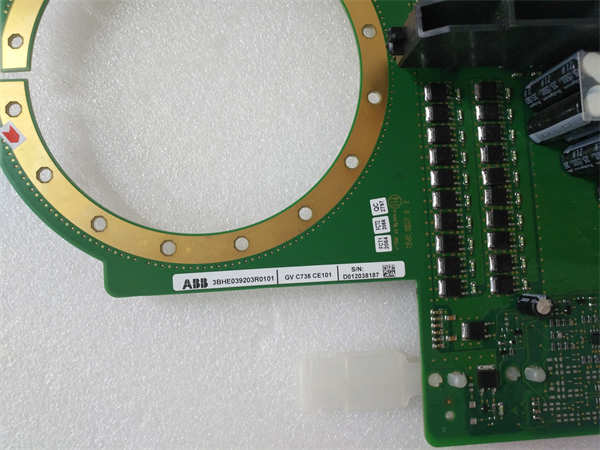

- Product Model: GVC736CE101

- ABB Order Code: 3BHE039203R0101

- Manufacturer: ABB

- System Family: UNITROL 6800 / EXC6800 excitation platform

- Function: Central processing unit for closed-loop voltage regulation, field current control, and grid-support functions

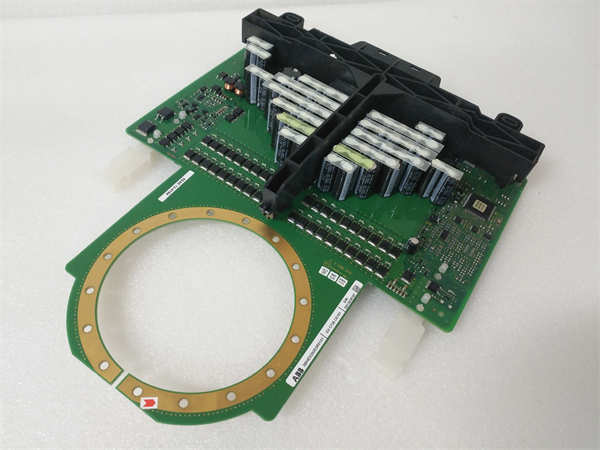

- Processor Type: Embedded real-time CPU with dedicated co-processors for fast Fourier transform (FFT) and vector control

- Memory: Onboard flash and RAM (non-volatile configuration storage)

- Interfaces: Backplane communication to I/O modules (e.g., GFD563A102 gate drivers), RS-232 service port, and optional Ethernet for diagnostics

- Redundancy: Supports 1+1 hot standby configuration with synchronization link

- Mounting: Plug-in module in standard EXC6800 chassis

- Firmware Dependency: Tightly coupled to specific software releases; mismatched firmware can cause boot failure or erratic behavior

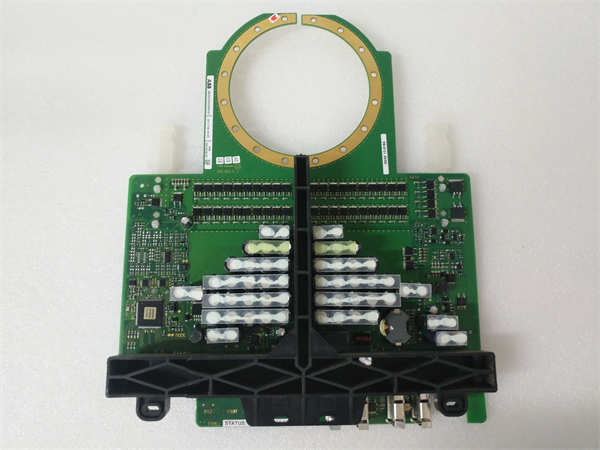

ABB 3BHE039203R0101 GVC736CE101

System Role and Downtime Impact

The GVC736CE101 serves as the computational core of ABB’s EXC6800 excitation system, deployed globally on thermal, hydro, and nuclear generators ranging from 50 MVA to over 1,500 MVA. It continuously calculates thyristor firing angles based on terminal voltage, reactive power demand, and grid conditions, while enforcing critical limits such as V/Hz, underexcitation (UEx), and overexcitation (OEx).

This module is typically configured in redundant pairs, but many older installations operate with a single unit due to cost constraints. A failure—whether from hardware fault, firmware corruption, or configuration loss—triggers an immediate transfer to manual mode or, more commonly, a complete excitation shutdown. This activates ANSI 40 (Loss-of-Field) or ANSI 59 (Overvoltage) relays, resulting in a forced turbine-generator trip. In non-redundant systems, recovery time depends entirely on spare availability, potentially leading to days of lost generation and significant grid stability penalties.

Reliability Analysis and Common Failure Modes

Despite its industrial-grade design, the GVC736CE101 exhibits age-related vulnerabilities common to early-2000s embedded control hardware:

- Flash memory wear-out: Repeated firmware updates or power cycling degrade NAND cells, leading to boot failures or parameter corruption.

- Battery-backed SRAM failure: The onboard coin-cell or capacitor used to preserve real-time clock and transient logs dries out after 8–12 years, causing configuration resets.

- Backplane connector fretting: Thermal expansion cycles induce micro-movements in edge connectors, increasing contact resistance and causing intermittent communication with I/O modules.

- Power supply ripple sensitivity: Internal DC-DC converters become less stable as filtering capacitors age, making the CPU susceptible to noise-induced resets during field current transients.

- Firmware version lock-in: Upgrading or replacing the module often requires exact firmware alignment with the rest of the EXC6800 rack—a major challenge when original engineering files are lost.

Preventive maintenance recommendations include:

- Performing annual backup of controller configuration via ABB’s legacy ControlIT or Excitation Commissioning Tool

- Inspecting and replacing the onboard backup battery during scheduled outages

- Monitoring diagnostic logs for “CPU Watchdog Reset” or “I/O Sync Loss” events

- Storing spares in climate-controlled, ESD-safe environments with periodic power-up tests

ABB 3BHE039203R0101 GVC736CE101

Lifecycle Status and Migration Strategy

ABB has officially discontinued the GVC736CE101 as part of its strategic shift toward the UNITROL 8000 platform. While limited technical documentation remains accessible through ABB’s legacy support portal, no new units are manufactured, and factory repair services have been phased out.

Short-term risk mitigation includes:

- Procuring and functionally testing at least two verified spares from ABB-certified surplus channels

- Engaging specialized third-party firms capable of board-level repair or firmware recovery

- Implementing external monitoring (e.g., PLC-based watchdog) to detect early signs of controller degradation

The long-term solution is migration to UNITROL 8000, which replaces the GVC736CE101 with the GVC836 module—offering enhanced cybersecurity (IEC 62443 compliance), built-in wide-area damping control (WADC), and simplified spare parts structure. Migration entails:

- Replacing the EXC6800 chassis with EXC8000 hardware

- Reconfiguring control algorithms in PCM600 or ABB Ability™ Electrical Distribution

- Recalibrating PSS, V/Hz limiters, and field forcing parameters per IEEE Std 421.5

- Conducting full dynamic performance validation under load rejection and islanding scenarios

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: