Description

Technical Specifications (For Spare Part Verification)

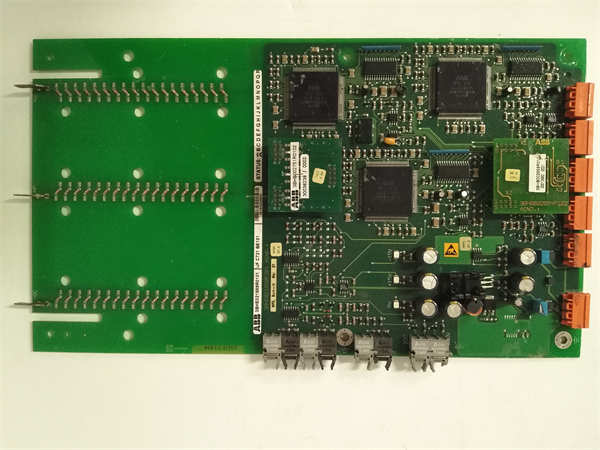

- Product Model: 3BHE021889R0101

- Manufacturer: ABB

- System Platform: AC 800M within System 800xA

- Module Type: Central Processing Unit (CPU)

- Memory: 4 MB application memory, 2 MB flash for program storage

- Execution Speed: ~10 k instructions per second

- Communication Interfaces: Dual Profibus DP ports (integrated), MB300 backplane for I/O and redundancy

- Redundancy Support: Hot-standby with UFC721BE101 pair via fiber-optic sync link

- Power Consumption: Approx. 8 W

- Firmware Requirement: Compatible with Control Builder M versions up to v5.1 SP2

- Physical Form: Standard AC 800M module (160 mm height, DIN-rail mountable)

System Role and Downtime Impact

The UFC721BE101 serves as the central brain of an AC 800M controller station in ABB’s System 800xA. It runs all user-defined control logic (e.g., PID loops, interlocks, sequences) and manages real-time data exchange with local I/O modules, operator stations, and engineering tools. In a non-redundant configuration, failure of this module—whether due to power anomaly, memory corruption, or hardware fault—results in an immediate and total loss of automated control for all associated field devices. In critical processes such as boiler combustion, chemical reactor temperature regulation, or water treatment dosing, this can trigger safety shutdowns, environmental excursions, or production losses exceeding $50,000 per hour. Even in redundant setups, a faulty primary CPU may cause unnecessary switchover events that destabilize the process.

Reliability Analysis and Common Failure Modes

The UFC721BE101, introduced in the early 2000s, exhibits age-related reliability challenges typical of embedded industrial controllers from that era. The most prevalent failure mode is program execution halt or watchdog timeout, often traced to degradation of the onboard flash memory or DRAM chips after 10–15 years of continuous operation. Symptoms include unresponsive communication, cyclic redundancy check (CRC) errors during download, or spontaneous reboots.

A notable design weakness is its dependence on stable 24 VDC backplane power: voltage sags below 20 V—even for milliseconds—can corrupt the program image or cause the CPU to enter a fault state requiring manual reset. Additionally, the module lacks modern cybersecurity features (e.g., secure boot, firmware signing), making it vulnerable to configuration tampering if connected to unsecured networks.

For preventive maintenance, site teams should:

- Perform annual backup verification of the application project and firmware image

- Monitor CPU load and scan time trends via Control Builder M online diagnostics

- Ensure clean, regulated power to the AC 800M rail with <5% ripple

- Keep at least one verified spare unit powered periodically (every 6 months) to refresh memory cells

ABB 3BHE021889R0101 UFC721BE101

Lifecycle Status and Migration Strategy

ABB has formally discontinued the UFC721BE101 and recommends migration to the PM864A (3BSE040860R1) or PM865A (3BSE040861R1) as part of a CPU upgrade path. These newer CPUs offer significantly higher performance, larger memory, enhanced security, and long-term support. However, migration is not drop-in compatible: it requires recompilation of the control application in a newer version of Control Builder M (v6.0+), potential I/O re-mapping, and thorough functional testing.

Continued reliance on the UFC721BE101 entails growing risk: no factory repairs, no firmware updates, and increasing difficulty sourcing tested spares. As interim measures, facilities may:

- Acquire 1–2 units from certified surplus vendors with full functional test reports

- Implement strict environmental controls (temperature <40°C, humidity <70%) to extend service life

- Isolate the controller network from corporate IT infrastructure to reduce cyber exposure

For sustainable operation, a planned migration to PM864/865 is strongly advised. This typically involves:

- Freezing the existing logic and performing impact analysis

- Upgrading the engineering station to Control Builder M v6.x

- Rebuilding the hardware configuration with the new CPU

- Conducting factory acceptance testing (FAT) before site cutover

While requiring capital investment, this path restores OEM support, improves system resilience, and aligns with modern industrial automation standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: