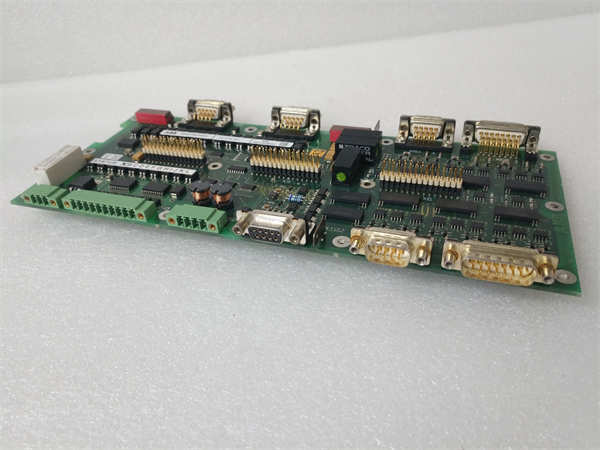

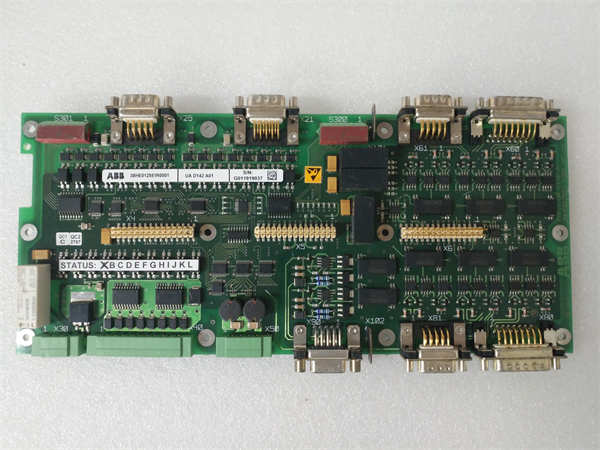

Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: UAD142A01

- ABB Order Code: 3BHE012551R0001

- Manufacturer: ABB

- System Family: AC 800M (part of System 800xA architecture)

- Function: 16-channel isolated digital input module

- Input Type: 24 V DC (sinking or sourcing, depending on wiring)

- Input Voltage Range: 15–30 V DC nominal

- Isolation: Channel-to-backplane isolation (typically 500 V RMS)

- Response Time: < 10 ms per channel

- Diagnostic Features: Group fault indication via LED and backplane communication

- Mounting: Plug-in module in standard AC 800M I/O baseplate (e.g., TB510/TB520)

- Compatibility: Requires compatible terminal base (e.g., TBD142A01) with screw or spring terminals

System Role and Downtime Impact

System Role and Downtime Impact

The UAD142A01 is a foundational I/O component in AC 800M-based control systems across power generation, water/wastewater, mining, and manufacturing. It interfaces critical binary field signals—such as pump status, limit switches, ESD pushbuttons, and fire/gas detector alarms—to the central controller.

While a single module failure typically affects only 16 signals, those signals often include safety-critical or interlock-related inputs. Consequences may include:

- Loss of “pump running” feedback, causing false trip of standby sequences

- Missing “valve closed” confirmation, blocking startup procedures

- Inability to detect emergency stop activation

- Degraded situational awareness for operators during abnormal events

Unlike CPU or communication failures, UAD142A01 faults may not trigger immediate plant shutdown—but they erode system integrity and increase manual intervention risk. Replacement requires physical access to the I/O cabinet and matching of terminal base configuration.

Reliability Analysis and Common Failure Modes

Despite robust design, modules in service beyond 10–15 years show age-related vulnerabilities:

- Optocoupler degradation: Input isolation components (optoisolators) lose CTR (current transfer ratio) over time, leading to missed signal transitions or intermittent reads.

- Input clamping diode failure: Repeated voltage transients from field wiring can damage protection circuits, causing shorted or open inputs.

- Backplane connector corrosion: Oxidation on edge fingers increases contact resistance, resulting in communication loss with the controller—even if the module powers up.

- PCB trace fatigue: Thermal cycling induces micro-cracks near high-current paths or terminal blocks, especially in high-vibration environments.

- Label/revision mismatch: Replacement units must match hardware revision and firmware compatibility; older revisions may not be recognized by newer AC 800M CPUs.

Recommended preventive actions:

- Perform periodic functional tests of critical DI channels during maintenance outages

- Inspect terminal tightness and shielding continuity annually

- Monitor system diagnostics for “I/O Module Fault” or “Channel Error” logs

- Maintain at least one tested spare per I/O cabinet type in inventory

Lifecycle Status and Migration Strategy

Lifecycle Status and Migration Strategy

ABB has discontinued the UAD142A01 as part of its transition toward higher-density and Ethernet-enabled I/O platforms. While the AC 800M system remains supported, this specific module is no longer produced, and factory repair is unavailable.

Short-term mitigation includes:

- Sourcing verified-used units from decommissioned sites or industrial surplus vendors

- Using functionally equivalent third-party I/O modules (with external isolation) where safety certification allows

- Consolidating non-critical DI signals onto remaining healthy modules to reduce exposure

The strategic migration path is upgrading to current-generation ABB I/O such as:

- UDC142A01 (modern replacement with enhanced diagnostics)

- TB550-series remote I/O with PROFINET or Modbus TCP interface

- Integration with ABB Ability™ System 800xA for unified asset visibility

Migration typically involves:

- Replacing terminal bases and I/O modules in batches

- Updating I/O tags in Control Builder M with minimal logic changes

- Leveraging existing multi-pair cabling to field devices

- Enhancing cybersecurity posture through network segmentation

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp:  System Role and Downtime Impact

System Role and Downtime Impact Lifecycle Status and Migration Strategy

Lifecycle Status and Migration Strategy