Description

Technical Specifications (For Spare Part Verification)

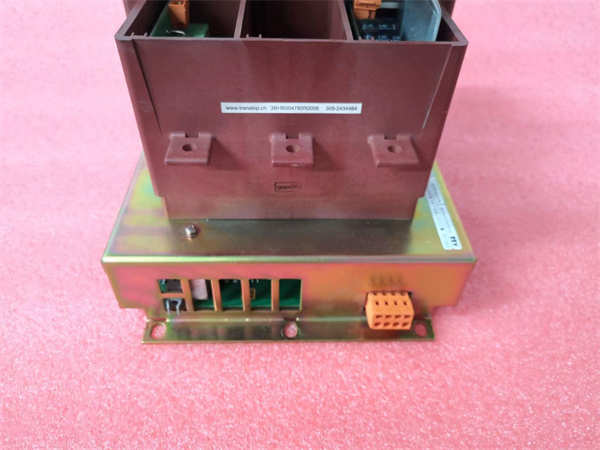

- Product Model: KUC755AE106

- Manufacturer: ABB

- System Family: AC 800M Distributed Control System (DCS)

- Processor Type: PowerPC-based embedded CPU

- Memory: Integrated program and data memory (non-user-expandable)

- Redundancy Support: Yes – supports 1:1 hot standby with identical KUC755AE106 module

- Backplane Interface: Proprietary ABB I/O bus (connects to CI854A or similar communication modules)

- LED Indicators: RUN, STOP, REDUNDANCY, ERROR, and I/O status LEDs

- Mounting: DIN rail via mounting bracket in standard AC 800M controller rack

- Power Consumption: Approx. 15 W (from backplane 24 VDC supply)

- Firmware Dependency: Requires specific firmware version matching project configuration in Control Builder M

System Role and Downtime Impact

The ABB KUC755AE106 is the central processing unit at the heart of the AC 800M DCS architecture, commonly deployed in power plants, oil & gas facilities, and large-scale industrial processes commissioned between 2005 and 2015. It executes all control logic, manages I/O scanning, handles communication with engineering stations, and coordinates with redundant partner units. In a non-redundant setup, failure of this module halts all control loops under its jurisdiction—leading to immediate safety system activation or full process trip. Even in redundant configurations, loss of one unit increases vulnerability; if the remaining unit fails before replacement, total control is lost. Given its irreplaceable role without an exact-match spare, the absence of a validated KUC755AE106 introduces severe operational continuity risk.

Reliability Analysis and Common Failure Modes

Although designed for industrial reliability, the KUC755AE106 exhibits age-related degradation consistent with early-2000s embedded computing hardware. The most prevalent failure mode is internal flash memory corruption, often triggered by repeated power cycling or voltage sags, leading to boot failures or unpredictable runtime behavior. Electrolytic capacitors on the power regulation circuitry degrade over time (typically after 10–12 years), causing intermittent resets or inability to maintain stable operation under load. Additionally, the module’s reliance on battery-backed RAM for temporary data during transitions makes it vulnerable to configuration drift if the supercapacitor or backup battery fails—a common issue in units not maintained per ABB’s service bulletins.

Design weaknesses include:

- Non-replaceable onboard memory – failure requires full module replacement

- Sensitivity to electrostatic discharge (ESD) during handling

- Limited thermal margin in high-ambient installations (>45°C)

Preventive maintenance recommendations:

- Perform annual backup of entire project configuration via Control Builder M

- Monitor module temperature during operation (should remain <60°C surface temp)

- Verify redundancy synchronization status weekly in redundant systems

- Replace backup supercapacitor every 8 years if accessible (requires factory service)

ABB KUC755AE106 3BHB005243R0106

Lifecycle Status and Migration Strategy

ABB officially marked the KUC755AE106 as discontinued in 2018, with end-of-support concluded by 2022. No new units are manufactured, and existing inventory is restricted to refurbished or used stock. Continued operation without a tested spare exposes facilities to extended downtime, as lead times for verified units can exceed 12 weeks.

As an interim measure, operators may:

- Acquire and functionally test 1–2 spares from certified surplus channels

- Implement strict environmental controls (cooling, clean power) to extend service life

- Enforce redundancy in all critical applications to mitigate single-point failure

For long-term sustainability, ABB recommends migration to the AC 800M PM866A/PM867 controller platform (order codes 3BSE038689R1 / 3BSE042335R1). This upgrade path requires:

- Replacement of the entire controller rack (new baseplate and power supply)

- Reconfiguration of I/O assignments in Control Builder M (hardware-independent design simplifies this)

- Potential recompilation of application logic due to updated runtime environment

While not a drop-in replacement, the PM866A series offers enhanced processing power, cybersecurity features, and extended lifecycle support through at least 2035. A phased migration during planned outages is the industry-standard approach to eliminate obsolescence risk while preserving existing I/O investments.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: