Description

Key Technical Specifications (For Spare Part Verification)

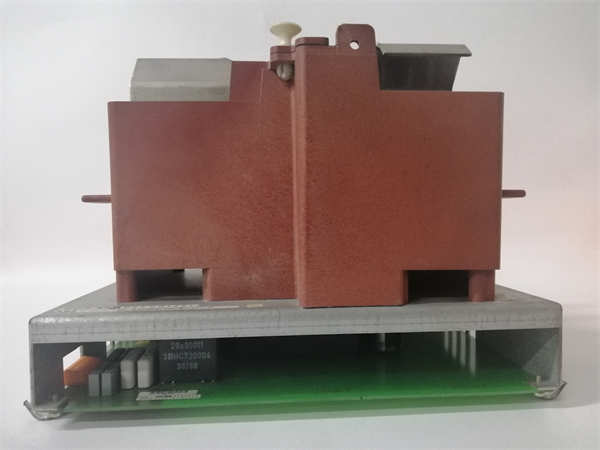

- Product Model: 3BHB004661R0001

- Manufacturer: ABB

- Module Identifier: KUC711AE

- System Family: AC 800M (part of System 800xA)

- Processor Type: PowerPC-based embedded CPU

- Memory: 16 MB application memory (non-expandable)

- Execution Speed: ~30 ms cycle time for typical logic load

- Communication Interfaces: Dual redundant Profibus DP (via CI854), internal backplane to I/O modules

- Redundancy Support: Yes (requires KUC711AE pair and synchronization cable)

- Power Supply: +5 V and ±12 V from AC 800M baseplate

- Firmware Compatibility: Requires Control Builder M versions up to v5.1 SP2; not compatible with v6+ without recompilation

- Mounting: Standard AC 800M rail-mounted chassis with TB840A/TB850A baseplates

-

3BHB004661R0001 KUC711AE

System Role and Downtime Impact

The KUC711AE serves as the brain of an AC 800M control station, commonly deployed in power generation, water treatment, mining, and process industries. It runs safety-critical or continuous-process logic—such as boiler sequencing, conveyor interlocks, or pump control—and coordinates all local I/O modules. In redundant configurations, it synchronizes state with its partner CPU to enable seamless failover. If a single (non-redundant) KUC711AE fails, the entire control station stops executing logic, leading to loss of automatic control, alarms flooding the operator station, and potentially a plant-wide trip if the station governs critical safety functions. Even in redundant setups, repeated CPU failures can exhaust spare capacity and expose the system to total outage.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, this module is now well beyond its intended service life (typical design life: 10–15 years), making component aging a primary concern.

- Common Failure Modes:

- Flash memory wear-out causing corrupted application downloads or boot loops.

- Electrolytic capacitors on the DC/DC converter section drying out, leading to voltage instability and random resets.

- Battery-backed SRAM failure (if equipped), resulting in loss of retained variables after power loss.

- Design Weaknesses:

- Limited thermal margin; sustained ambient temperatures above 50°C accelerate semiconductor degradation.

- No onboard Ethernet port—relies entirely on external communication modules, increasing system complexity and failure points.

- Preventive Maintenance Recommendations:

- Perform annual backup of the compiled application (.prg file) and hardware configuration.

- Inspect CPU module for bulging capacitors or discoloration near power regulators.

- Ensure adequate ventilation in the I/O cabinet; clean dust filters quarterly.

- Test redundant CPU switchover during planned outages to verify synchronization integrity.

-

3BHB004661R0001 KUC711AE

Lifecycle Status and Migration Strategy

ABB officially discontinued the KUC711AE over a decade ago. Technical support is limited to break-fix scenarios, and firmware updates are frozen. Continuing to operate this hardware carries significant risk due to unavailability of new spares and incompatibility with modern cybersecurity requirements.

- Interim Solutions:

- Source only from vendors who provide full functional validation, including logic execution test, memory integrity check, and redundancy sync verification.

- Maintain at least two tested spares per critical control station.

- Migration Path:

- ABB’s recommended upgrade path is to replace the KUC711AE with the KUC755AE or KUC757AE, which offer:

- Higher processing power (sub-10 ms cycle times),

- Integrated Ethernet for direct 800xA connectivity,

- Support for Control Builder M v6.x and later, including enhanced security features.

- Migration requires:

- Re-compilation of the application in a compatible Control Builder version,

- Possible re-engineering of I/O assignments due to memory map differences,

- Validation of all control sequences and HMI tags.

- For facilities with budget constraints, a “like-for-like” refurbishment strategy combined with strategic redundancy is acceptable as a short-to-mid-term bridge—but a formal migration plan should be in place within 24 months.

- ABB’s recommended upgrade path is to replace the KUC711AE with the KUC755AE or KUC757AE, which offer:

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: