Description

Technical Specifications (For Spare Parts Verification)

- Model: 3BHB002916R0001

- Functional Designation: UFC721AE

- Manufacturer: ABB

- System Platform: AC 800F within Advant Open Control System (OCS) / Industrial IT architecture

- Processor: Motorola PowerPC-based embedded CPU (typically MPC860 or equivalent)

- Memory: Onboard RAM and flash (size varies by firmware version; typically 16–32 MB)

- Communication Interfaces: Dual redundant Profibus DP for I/O, Ethernet for engineering access (TCP/IP)

- Redundancy Support: Hot-standby capable when paired with identical UFC721AE in redundant configuration

- Operating Temperature: 0°C to +60°C (industrial grade)

- Firmware Dependency: Tightly coupled with CB510/CB520 control builder software versions

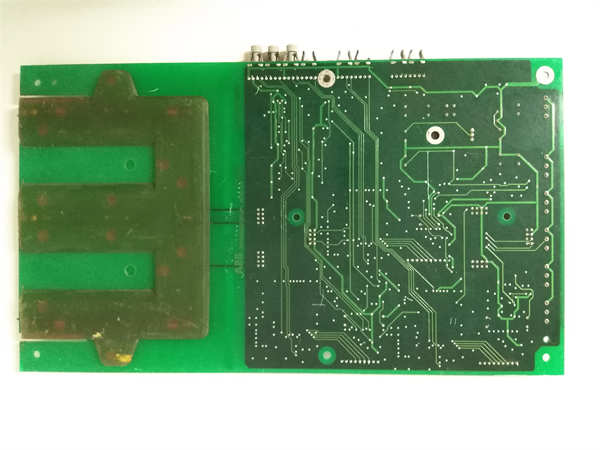

- Physical Form: DIN rail or rack-mounted module with status LEDs (RUN, STOP, COMM, REDUNDANCY)

System Role and Downtime Impact

The UFC721AE serves as the brain of the AC 800F field controller, a key component in ABB’s legacy distributed control systems deployed widely in power generation, oil & gas, and heavy industry. It runs user-downloaded control applications, scans local I/O via Profibus, executes safety and regulatory logic, and communicates with operator workstations and higher-level systems. In a non-redundant setup, failure of this module results in immediate loss of automated control over an entire process unit—potentially triggering emergency shutdowns, safety interlocks, or manual intervention. Even in redundant configurations, a faulty primary unit can cause switchover instability or communication loss if the standby unit is mismatched or uncalibrated. Recovery requires not only hardware replacement but also precise firmware and application synchronization.

Reliability Analysis and Common Failure Modes

Despite its industrial design, the UFC721AE exhibits age-related vulnerabilities common to early-2000s embedded controllers:

- Flash memory wear-out – repeated firmware updates or long-term operation can degrade onboard flash, leading to boot failures or corrupted application images.

- Power supply capacitor aging – internal electrolytic capacitors dry out over time, causing voltage instability under load and intermittent resets.

- Profibus communication chip failure – the dedicated ASIC or transceiver for Profibus DP is sensitive to ground loops or ESD, resulting in I/O scan loss.

- Ethernet PHY degradation – network connectivity may become unreliable due to aging magnetics or PHY IC failure, hindering diagnostics and downloads.

A notable design limitation is the absence of built-in health monitoring for storage or memory integrity, making latent faults hard to detect before catastrophic failure. For preventive maintenance, operators should:

- Maintain a known-good backup of the application and firmware

- Periodically verify redundancy synchronization status

- Inspect for bulging capacitors or discoloration on the PCB during cabinet inspections

- Ensure clean, stable 24 VDC power with low ripple to minimize stress on internal regulators

ABB 3BHB002916R0001 UFC721AE

Lifecycle Status and Migration Strategy

ABB has formally ended support for the AC 800F platform, including the UFC721AE. No new units are manufactured, and official technical assistance is restricted to paid legacy contracts. Continuing to operate systems with this controller carries escalating risk: spare units are scarce, firmware mismatches are common, and cybersecurity vulnerabilities cannot be patched.

As an interim measure, facilities may source tested units from specialized surplus vendors—but each must be validated for:

- Correct hardware revision (e.g., “AE” suffix denotes specific I/O or memory config)

- Ability to load and run the existing control application

- Stable Profibus and Ethernet communication under load

For long-term sustainability, ABB recommends migration to the AC 800M or Ability™ System 800xA platforms. The typical path involves:

- Replacing AC 800F controllers with AC 800M CPUs (e.g., PM86x series)

- Upgrading I/O to S800 or S900 modules with Profibus or PROFINET support

- Converting control logic using ABB’s conversion tools (though significant re-engineering is usually required)

Alternative strategies include third-party emulation or “wrap-around” solutions that retain field wiring while replacing the controller with a modern PLC running translated logic. Regardless of approach, migration demands thorough functional testing, safety validation, and operator retraining—making early planning essential to avoid unplanned outages due to sudden hardware failure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: