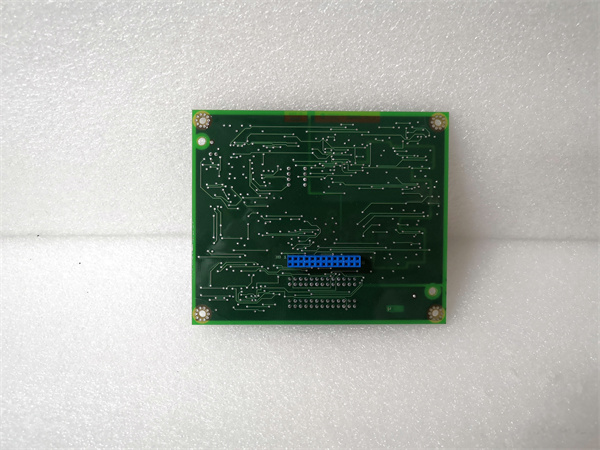

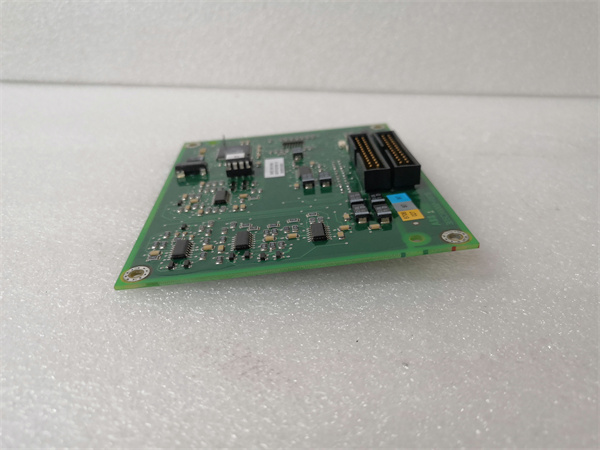

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: 3ASC25H216A DATX132

- Manufacturer: ABB

- System Platform: AC 800M / System 800xA with S800 I/O

- Module Type: DATX132 – Dual-channel redundant digital input/output termination unit

- Compatible I/O Modules: Designed for use with DI840, DO840, and other redundant S800 I/O modules

- Wiring Configuration: Screw-type terminal blocks for field device connections (supports 0.14–2.5 mm² wires)

- Redundancy Support: Enables 1oo2 (one-out-of-two) or 2oo2 voting logic for safety-critical applications

- Mounting: DIN rail mounted alongside S800 I/O modules on standard mounting base (e.g., 206-00212)

- Operating Temperature: 0°C to +60°C

- Certifications: CE, UL 508, IEC 61010-1

System Role and Downtime Impact

The ABB 3ASC25H216A DATX132 serves as the critical field-wiring interface for redundant digital I/O channels in AC 800M-based control systems. It is typically deployed in high-availability applications such as boiler safety systems, emergency shutdown (ESD) logic solvers, or critical motor control circuits where dual-channel redundancy is mandated. This module does not process logic but provides the physical and electrical pathway between redundant I/O cards and field instruments (e.g., pressure switches, valve feedback contacts). If this termination unit fails—due to terminal corrosion, internal trace damage, or connector degradation—it can cause loss of signal on one or both redundant channels, potentially triggering a spurious trip or, worse, masking a real fault due to undetected channel dropout. In safety-instrumented systems (SIS), such a failure could compromise the entire redundancy architecture, leading to unscheduled plant shutdowns or regulatory non-compliance.

Reliability Analysis and Common Failure Modes

Although robustly built, the DATX132 is susceptible to age-related degradation common in legacy industrial hardware. The most frequent failure modes include oxidation or loosening of screw terminals due to thermal cycling, which increases contact resistance and causes intermittent signals. Internal PCB traces, especially near high-current switching paths, may develop micro-cracks over time, particularly in environments with vibration or humidity ingress. Unlike active electronics, this module lacks self-diagnostics, so failures are often detected only after a process upset. A key design vulnerability is its reliance on mechanical integrity—there is no electronic monitoring of terminal health. Additionally, because it is used in redundant pairs, partial failure (e.g., one channel degrading while the other remains functional) may go unnoticed during routine checks. For preventive maintenance, technicians should perform annual inspections: torque-check all terminals, verify continuity across redundant paths, inspect for discoloration or arcing marks, and ensure the module is securely seated on its base. Cleaning with contact-safe solvent and reseating the module can resolve many latent issues before they escalate.

ABB 3ASC25H216A DATX132

Lifecycle Status and Migration Strategy

ABB has officially discontinued the 3ASC25H216A DATX132 as part of the broader phase-out of early S800 redundant I/O components. No direct replacement is offered under the same part number, and new units are unavailable through official distribution channels. Continued use carries substantial risk: spare parts are scarce, pricing is unstable, and technical support for troubleshooting is limited. As a temporary measure, facilities may source tested-used units from certified surplus suppliers or explore board-level repair services for units with minor damage. However, the sustainable path is migration. ABB’s recommended upgrade route involves transitioning to the newer DATX132N (if still available) or, more commonly, redesigning the I/O architecture using the S800 I/O with DATX232 termination units, which offer improved diagnostics and compatibility with current AC 800M CPUs (e.g., PM866A). This migration typically requires re-engineering the I/O allocation, updating Control Builder M projects, and re-terminating field wiring—but eliminates long-term obsolescence risk. For critical systems, a phased approach—starting with non-safety loops—is advised to manage cost and operational impact.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: