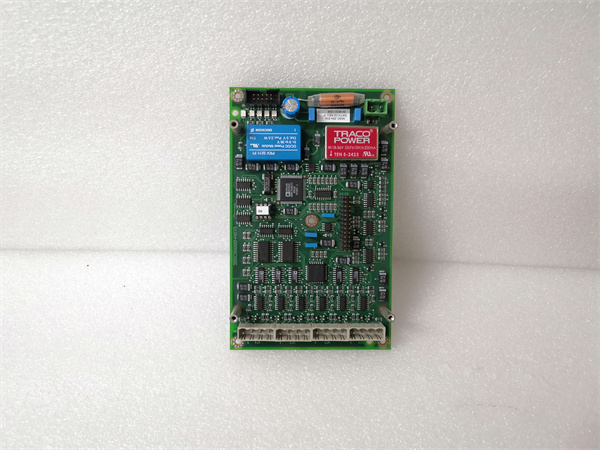

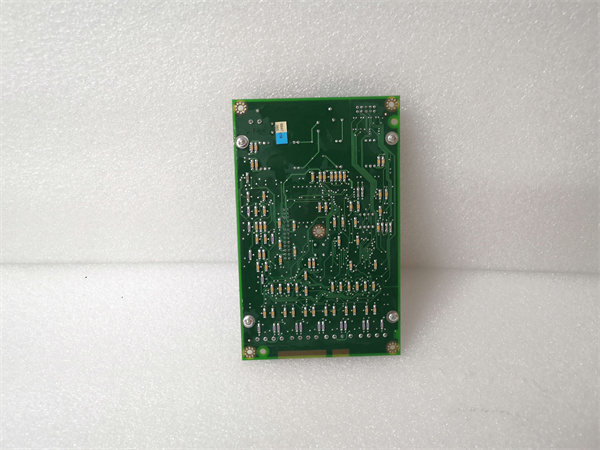

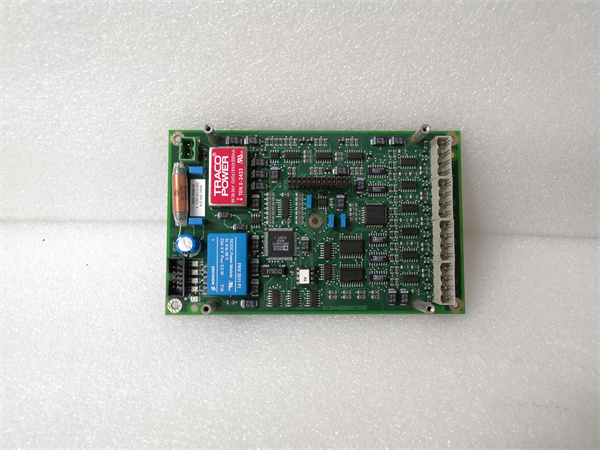

Description

Key Technical Specifications (For Spare Part Verification)

- Product model: 3ASC25H214 DATX130

- Manufacturer: ABB

- Compatible system: Triconex Classic platform (typically with 36xx-series output modules)

- Function: 16-channel digital output termination with individual fuse protection and LED indication

- Output type: Relay contact or solid-state switching interface (depending on paired I/O module)

- Field voltage support: Up to 250 V AC / 125 V DC (as dictated by connected output module and external power)

- Isolation: Galvanic separation between logic backplane and field wiring via terminal design

- Connector type: Removable screw-terminal block with integrated fuse holders (typically 1–2 A fast-blow fuses per channel)

- Diagnostic features: Per-channel LED for output status; fuse blown indication via visual inspection

- Mounting: DIN rail or dedicated Triconex I/O chassis with carrier base

- Environmental rating: Industrial temperature range (-20°C to +70°C), non-condensing humidity

System Role and Downtime Impact

The ABB DATX130 acts as the critical field-side interface for safety-critical output commands in Triconex-based emergency shutdown (ESD) and fire & gas (F&G) systems. It distributes signals from triple-modular redundant output modules to final elements—such as blowdown valves, deluge system solenoids, or turbine trip relays. Although it contains no active logic, its integrity is vital: a failed fuse, loose terminal, or corroded contact can prevent a safety command from reaching its destination. In high-hazard applications, this could delay or inhibit a required shutdown, increasing process risk. Even in non-trip scenarios, loss of multiple outputs often forces manual override or partial unit derating. Replacement without a verified spare typically requires a controlled system outage, as hot-swapping is not supported in most legacy Triconex installations.

Reliability Analysis and Common Failure Modes

The DATX130’s reliability is primarily challenged by mechanical and environmental factors. The most common failure mode is fuse degradation or nuisance blowing, caused by inrush currents from solenoid valves or minor ground faults that accumulate over time. A second frequent issue is terminal oxidation or loosening, particularly in coastal or chemical plants, leading to high-resistance connections and incomplete actuator energization. Additionally, LED indicator failure impairs troubleshooting during diagnostics, while plastic housing embrittlement after decades of thermal cycling can cause terminal block cracking during maintenance.

Design limitations include the absence of remote fuse status monitoring and dependence on manual visual checks. As a preventive measure, maintenance teams should: (1) inspect and replace fuses proactively during major outages—even if not blown; (2) torque all terminals to specification using a calibrated tool; (3) verify actual field device operation during functional safety tests, not just logic-side signals; and (4) store at least one fully assembled and tested spare DATX130 with matching fuse ratings and terminal hardware.

ABB 3ASC25H214 DATX130

Lifecycle Status and Migration Strategy

ABB has officially discontinued the DATX130 series. No new production exists, and technical support is restricted to legacy documentation archives. Continued reliance introduces operational vulnerability due to aging components and shrinking spares pool.

Short-term mitigation includes sourcing used units with full load-testing validation or refurbishing existing modules by replacing fuses, terminals, and LEDs. The strategic path forward aligns with migration to Triconex v10/v11 (TMRx) systems, where modern output modules (e.g., 3604E) integrate fused, removable terminal carriers with diagnostic feedback—eliminating the need for discrete termination units like the DATX130. This upgrade requires: (1) replacement of I/O chassis and backplanes; (2) rewiring to new terminal standards; and (3) re-validation of all safety instrumented functions (SIFs) under IEC 61511. For facilities extending legacy system life, maintaining a “certified spare” DATX130—complete with fresh fuses and verified continuity—is a necessary risk-control measure to ensure safety system readiness.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: