Description

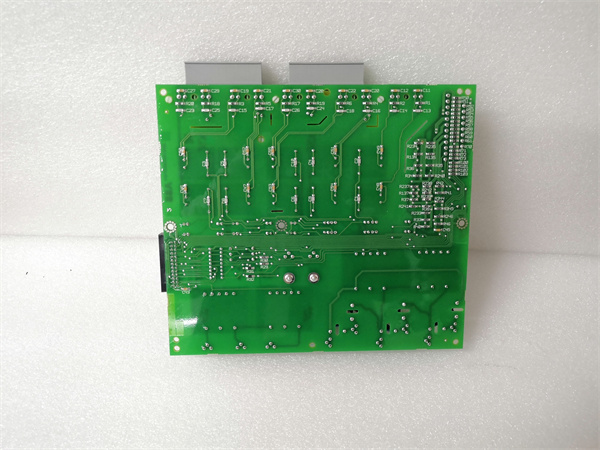

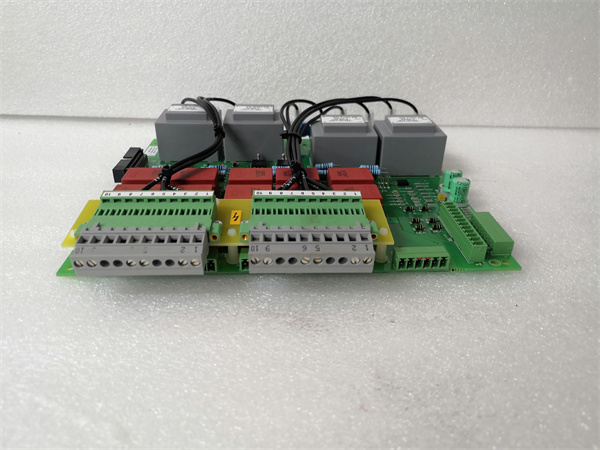

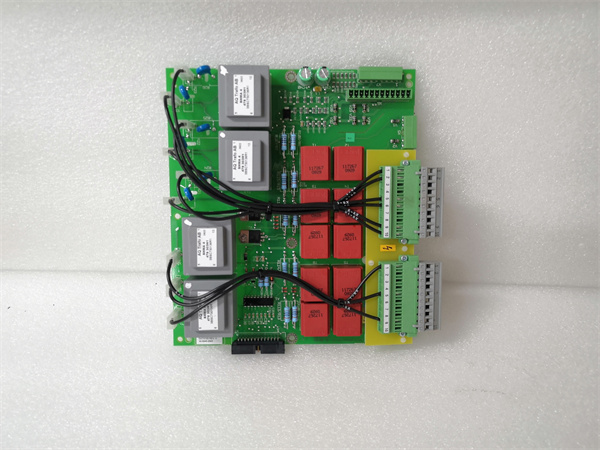

Technical Specifications (For Spare Parts Verification)

- Product Model: 3ASC25H208 DATX100

- Manufacturer: ABB

- System Platform: AC 800M with S800 I/O system

- Compatible Modules: Standard S800 I/O modules (e.g., DI810, DO810, AI810)

- Wiring Type: Screw-terminal field connections with removable terminal blocks (e.g., TB840A)

- Backplane Interface: DIN 41612 connector for power and data to S800 rail

- Power Distribution: Carries logic (+5 VDC) and auxiliary (±15 VDC / 24 VDC) power from backplane

- Mechanical Form: Half-width base occupying one slot in S800 I/O chassis

- Diagnostic Support: Passes module status LEDs to front; no active electronics

- Superseded By: DATX100-1 (3ASC25H209) with improved terminal retention and housing durability

- Certification: CE, UL, CSA (original manufacturing batch)

System Role and Downtime Impact

The DATX100 serves as the foundational interface between ABB’s S800 I/O modules and field instrumentation in AC 800M-based distributed control systems. Installed in large numbers across process industries, it enables secure screw-terminal wiring while ensuring reliable electrical contact with the system backplane. Though passive, its mechanical condition directly affects system reliability. A cracked housing, loose terminal, or corroded backplane pin can cause intermittent signals, channel dropouts, or complete loss of I/O communication—potentially triggering false alarms, control loop failures, or safety system trips. In critical applications such as boiler control or compressor protection, such faults may lead to partial or full plant shutdowns.

Reliability Analysis and Common Failure Modes

Despite having no active components, the DATX100 is vulnerable to long-term environmental and mechanical stress:

- Terminal screw loosening: Thermal cycling and vibration gradually reduce clamping force, increasing contact resistance or causing open circuits.

- Plastic embrittlement: Prolonged exposure to heat or UV light (in outdoor enclosures) makes the polycarbonate housing brittle, risking breakage during module replacement.

- Backplane contact oxidation: Humidity ingress leads to corrosion on DIN 41612 pins, impairing power delivery or data synchronization.

- Latch fatigue: The plastic retention clip that secures the I/O module can fracture after repeated insertions, allowing modules to dislodge unexpectedly.

Preventive maintenance should include periodic torque verification of terminal screws (per IEC 60947), visual inspection for cracks or discoloration, cleaning of backplane contacts with electronic-grade cleaner, and gentle handling during module swaps. Given its role as a signal gateway, even minor degradation can manifest as elusive intermittent faults that are difficult to diagnose.

ABB 3ASC25H208 DATX100

Lifecycle Status and Migration Strategy

ABB has discontinued the original DATX100 (3ASC25H208) and replaced it with the enhanced DATX100-1 (3ASC25H209), which features improved terminal block retention and more robust housing material. The two versions are mechanically and electrically compatible, allowing direct substitution without rewiring or reconfiguration.

For facilities still operating legacy AC 800M systems:

- New installations or repairs should use DATX100-1 where possible.

- Existing terminal blocks (e.g., TB840A) can typically be reused if undamaged.

Long-term, organizations planning system modernization should evaluate migration to S800 Compact or S900 I/O platforms, which offer higher density, integrated diagnostics, and better support for IIoT integration—but this requires chassis and cabling updates.

Until then, maintaining a small inventory of verified DATX100 or DATX100-1 bases for critical I/O channels is advisable. Including terminal base obsolescence in overall asset lifecycle planning helps avoid unexpected downtime due to mechanical failure in aging infrastructure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: