Description

Key Technical Specifications (For Spare Parts Verification)

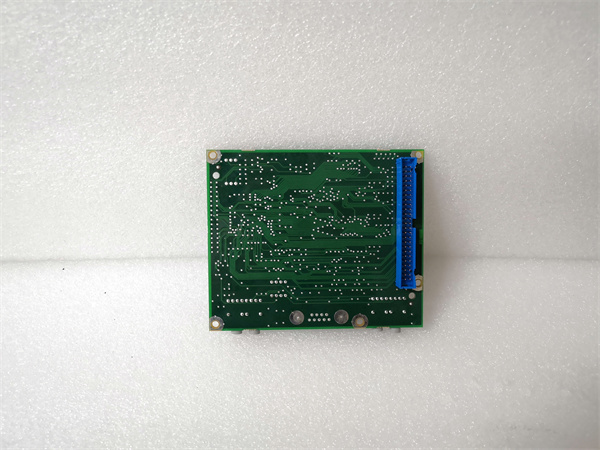

- Product Model: 3ASC25H204 DAPU100

- Manufacturer: ABB

- System Platform: AC 800PEC (Power Electronics Controller)

- Function: Digital I/O processing unit (DAPU100 variant)

- I/O Capacity: 32 digital inputs + 32 digital outputs (isolated, 24 V DC)

- Communication Interface: Proprietary high-speed backplane bus to PM866PEC CPU

- Mounting: DIN rail or rack-mounted within AC 800PEC chassis

- Power Supply: Supplied via system backplane (±15 V, +5 V)

- Diagnostic Features: LED indicators for power, communication, and channel status

- Firmware Dependency: Requires specific firmware version matching with PM866PEC controller

- Physical Dimensions: Approx. 220 mm (W) × 150 mm (H) × 80 mm (D)

System Role and Impact of Failure

The ABB 3ASC25H204 DAPU100 is a critical peripheral module in the AC 800PEC control system, which is widely deployed in high-performance power conversion applications such as HVDC transmission, static synchronous compensators (STATCOM), and large industrial drives. It serves as the primary interface between the central PM866PEC processor and field-level digital devices—such as gate drive enable signals, breaker status contacts, and interlock switches. If this module fails, the controller loses visibility and control over essential safety and operational signals, typically triggering a system trip or complete shutdown of the power converter. In utility-scale installations, such a failure can result in multi-hour outages, regulatory penalties, and significant revenue loss.

Reliability Analysis and Common Failure Modes

Although robustly engineered for demanding environments, the DAPU100 is susceptible to age-related degradation due to its design era (early-to-mid 2000s). The most common failure modes include electrolytic capacitor drying-out on the internal DC/DC converter circuits, leading to voltage instability; corrosion or oxidation on backplane connectors causing intermittent communication; and latch-up events from electrical transients on field wiring that damage input optocouplers. A key design vulnerability is its reliance on stable backplane power—any ripple or sag beyond tolerance can cause unexplained resets. Additionally, the module contains non-volatile memory backed by a small onboard battery (often a soldered coin cell), which, when depleted, may result in configuration loss during power cycles.

For maintenance teams, proactive measures are essential: inspect all field wiring for ground faults or induced noise, verify clean and secure seating in the chassis backplane, and monitor for sporadic communication errors in the control logs. While the unit itself has no user-serviceable parts, keeping spare units powered periodically (even offline) can help preserve component health and detect latent failures before deployment.

ABB 3ASC25H204 DAPU100

Lifecycle Status and Migration Strategy

ABB has officially discontinued the 3ASC25H204 DAPU100 as part of the broader AC 800PEC platform end-of-life. No new units are available from the manufacturer, and remaining inventory exists only in the secondary market, often at premium pricing and uncertain provenance. Continued use carries substantial risk: lack of warranty, no factory repair options, and increasing difficulty in verifying functional integrity.

As a temporary measure, facilities may consider board-level repair services from specialized third parties or implement redundant I/O architectures using existing spares to mitigate single-point failure risk. However, the long-term solution is migration. ABB’s recommended path is upgrading to the newer AC 800PEC X platform, which uses modernized I/O modules (e.g., 3ASC35H201) with enhanced diagnostics, Ethernet-based configuration, and extended support. This migration requires re-engineering of the I/O wiring, updated control application logic in Automation Builder, and re-commissioning—but it restores access to technical support, cybersecurity updates, and future-proof scalability. For asset owners, a phased migration plan, starting with critical spares inventory audit and ending with full platform replacement, is the most prudent approach to ensure decades-long operational continuity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: