Description

Key Technical Specifications (For Spare Parts Verification)

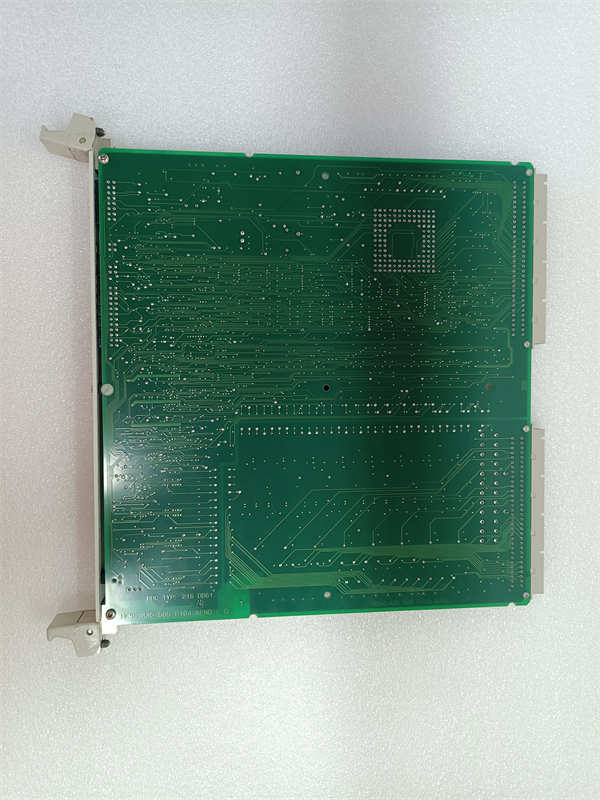

- Product Model: 216DB61

- Manufacturer: ABB

- System Family: AC800F / Freelance Distributed Control System (DCS)

- Module Type: Digital Input (DI), 32 channels

- Input Voltage: 24 V DC (sourced or sinked, depending on wiring)

- Input Isolation: Group isolation (typically 4 groups of 8 channels)

- Response Time: ≤ 1 ms per channel

- Backplane Compatibility: AC800F I/O rack (requires compatible base unit, e.g., 215AB61)

- Diagnostic Features: Channel-level LED indicators, module status via Freelance engineering tool

- Mounting: DIN rail in AC800F chassis

System Role and Downtime Impact

The ABB 216DB61 serves as a critical data acquisition point in AC800F-based control systems, converting field-level binary signals—such as limit switch positions, pump running status, or emergency stop contacts—into logical inputs for the controller. It is commonly deployed across multiple subsystems including material handling, utility monitoring, and safety circuits. Failure of this module results in loss of all 32 input signals, which may cause incorrect logic evaluation, disable safety functions, or trigger false alarms. In non-redundant applications, such a failure can lead to partial or complete process shutdown, particularly if the lost signals are part of interlock chains. Recovery requires physical replacement and re-verification of signal integrity, often extending downtime due to spare parts scarcity.

Reliability Analysis and Common Failure Modes

The 216DB61 generally exhibits robust mechanical design but suffers from component aging typical of modules produced in the early 2000s. The most common failure modes include degradation of optocouplers—used for input isolation—leading to signal dropout or erratic readings, especially under sustained high ambient temperatures. Additionally, terminal block corrosion or loose connections due to thermal cycling can cause intermittent contact failures that mimic field device faults. A known vulnerability is the lack of individual channel fusing; a short circuit on one input can affect an entire group of eight channels. For preventive maintenance, technicians should periodically inspect terminal tightness, clean dust and conductive debris from terminals, verify LED indicators against actual field states, and perform loop checks during scheduled outages. Keeping updated wiring diagrams and I/O lists is crucial for rapid troubleshooting.

ABB 216DB61

Lifecycle Status and Migration Strategy

ABB has formally discontinued the 216DB61 as part of the AC800F platform sunset, with no new units available through official channels since the mid-2010s. Continued use poses escalating risks: spare parts are increasingly unreliable, counterfeit or mismatched modules may enter the supply chain, and diagnostic support from ABB is minimal. Short-term mitigation includes securing verified used spares from trusted surplus vendors, implementing rigorous module testing before installation, or performing board-level repairs where feasible. However, the sustainable solution is migration to ABB’s current control architecture—System 800xA with AC 800M controllers. This involves replacing the AC800F I/O system with modern equivalents such as the DI810 (32-channel 24 V DC digital input module), which offers enhanced diagnostics, better noise immunity, and seamless integration with Control Builder M. While migration requires upfront investment in hardware and re-engineering, it eliminates obsolescence risk, improves system resilience, and ensures long-term access to technical support and cybersecurity updates.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: