Description

Key Technical Specifications (For Spare Part Verification)

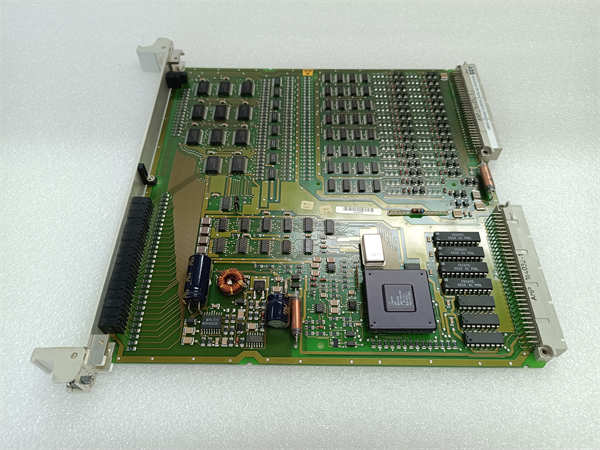

- Product Model: 216AB6

- Manufacturer: ABB

- System Family: Freelance 2000 / AC800F DCS

- Module Type: Central Processing Unit (CPU) for AC800F field station

- Firmware Compatibility: Requires legacy Freelance Engineering Tool (FET), typically versions prior to 2014

- Memory Configuration: Integrated SRAM with battery backup for program retention; non-expandable flash memory

- Communication Interfaces: Dual redundant Profibus DP for I/O modules; RS232 service port for diagnostics and upload/download

- Power Requirements: +5 V DC supplied via backplane; typical power draw approximately 5 W

- Mechanical Form Factor: DIN rail mount within standard AC800F rack (compatible with 216AA/AB chassis series)

- Diagnostic Indicators: Status LEDs for RUN, STOP, I/O bus activity, battery health, and error conditions

System Role and Downtime Impact

The ABB 216AB6 serves as the primary logic executor in an AC800F field control station within the Freelance DCS architecture. It manages all local I/O modules over Profibus DP, runs user-defined control strategies, and maintains communication with operator consoles and engineering workstations. A failure of this module results in immediate loss of automated control for its assigned process segment—commonly causing full shutdown of a production line, skid, or utility system. In continuous processes such as water treatment, chemical dosing, or batch manufacturing, this can trigger safety shutdowns, compromise product quality, and lead to extended unplanned downtime due to the difficulty in rapidly procuring verified replacement units.

Reliability Analysis and Common Failure Modes

Although engineered for industrial environments, the 216AB6 is subject to component aging after decades of service. The most prevalent failure mechanism is program loss caused by depletion of the internal lithium battery that preserves SRAM contents during power interruptions. Once battery voltage falls below ~2.7 V (typically after 8–12 years), configuration data is lost on reboot. Additional failure modes include electrolytic capacitor degradation leading to unstable internal voltages, oxidation or fretting corrosion on backplane connectors causing intermittent operation, and Profibus transceiver failures resulting in I/O communication faults. The module lacks modern transient protection, making it vulnerable to power surges or ground loops. Recommended preventive actions include annual battery voltage checks, visual inspection for capacitor bulging or leakage, cleaning of dust from ventilation paths, and verification of secure mechanical seating in the rack to ensure reliable electrical contact.

ABB 216AB6

Lifecycle Status and Migration Strategy

ABB has formally declared the 216AB6 obsolete as part of the end-of-life roadmap for the Freelance 2000 platform. No new units are available through official channels, and ABB no longer provides repair services, firmware updates, or technical documentation support. Continued reliance on this hardware entails substantial operational risk: spare parts are only accessible through surplus markets or third-party brokers, often at premium prices and without functional guarantees. Short-term mitigation includes strategic stocking of tested spares or engaging specialized electronics refurbishers for board-level repairs. However, the recommended long-term solution is system migration. ABB’s official upgrade path leads to the Freelance (Generation 3) platform based on AC900F controllers or integration into the System 800xA ecosystem using AC800M controllers. Such a migration necessitates re-engineering of control logic (due to transition from FET to Control Builder M), replacement of I/O subsystems, and potential network infrastructure updates. While requiring capital investment, this approach eliminates obsolescence exposure, enhances cybersecurity posture, and enables connectivity to modern SCADA, MES, and cloud-based monitoring systems.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: