Description

Technical Specifications (For Spare Parts Verification)

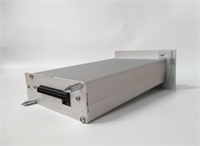

- Product Model: 1TGB302003R0003

- Manufacturer: ABB

- Compatible With: ABB AF30-30-11 and related AF30 contactor frames (AF series, ~1990s–2010s)

- Contact Configuration: 1 Normally Open (NO) + 1 Normally Closed (NC)

- Rated Operational Voltage: Up to 690 VAC

- Rated Insulation Voltage (Ui): 690 V

- Rated Impulse Withstand Voltage (Uimp): 6 kV

- Mechanical Life: Typically 10 million operations (dependent on base contactor)

- Mounting: Snap-on side-mount to AF30 contactor body

- Terminal Type: Screw clamp, suitable for 0.5–2.5 mm² conductors

- Operating Temperature Range: -25°C to +70°C

System Role and Downtime Impact

The 1TGB302003R0003 is an auxiliary contact block used in motor control centers, HVAC panels, and industrial machinery that employ ABB’s legacy AF30 contactors. It enables the control system to monitor the contactor’s energized state—critical for sequence logic, safety circuits, or remote status indication. While not a power-switching component, its failure can cause loss of feedback signals, leading to false “off” indications, failed start sequences, or bypassed safety checks. In systems where redundancy is absent (common in older designs), this single module can become a hidden point of failure. Because it is mechanically integrated with the contactor frame, incorrect or worn units may not latch properly, causing intermittent operation that is difficult to diagnose.

Reliability Analysis and Common Failure Modes

This auxiliary block is electromechanically simple but subject to long-term wear. The most frequent failure mode is contact erosion or oxidation, especially in high-cycle applications or environments with humidity and contaminants. Over time, the silver alloy contacts develop film resistance, leading to high-impedance connections that PLC inputs may interpret as “open,” even when the contactor is closed.

Secondary issues include:

- Plastic housing embrittlement due to UV exposure or thermal aging, causing cracks or poor snap-fit retention

- Loose terminal screws from vibration, resulting in arcing or signal dropout

- Mechanical misalignment after repeated removal/installation, preventing reliable actuation by the contactor arm

A design limitation is the lack of visual wear indicators—unlike main power contacts, auxiliary contacts offer no easy way to assess remaining life. Additionally, compatibility is strictly tied to the AF30 frame; newer ABB contactors (e.g., A-series) use different mounting geometries, making direct substitution impossible without replacing the entire contactor.

Preventive maintenance recommendations include:

- Performing continuity tests during scheduled outages using a low-voltage ohmmeter

- Verifying mechanical engagement with the contactor’s actuator lever

- Replacing auxiliary blocks proactively when servicing the main contactor

- Storing spares in dry, temperature-controlled conditions to prevent material degradation

ABB 1TGB302003R0003

Lifecycle Status and Migration Strategy

ABB has phased out the 1TGB302003R0003 under its legacy part numbering system. It is no longer listed in current ABB catalogs, and official support is limited to “as-available” spare parts or cross-reference guidance. Continued reliance on this component carries increasing risk due to dwindling genuine inventory and rising prices from secondary markets.

Short-term mitigation includes:

- Sourcing verified original parts from ABB-authorized surplus channels

- Using board-level inspection to validate authenticity (e.g., ABB logo, date code, material quality)

- Installing redundant monitoring (e.g., external proximity sensors) where critical

For long-term sustainability, the recommended path is to upgrade the entire contactor assembly to ABB’s current A-series platform. The modern equivalent would be:

- Contactor: ABB A30-30-11 (or AF30-30-11-11 if retaining AF form factor with updated internals)

- Auxiliary Block: ABB 1SFL427001R1100 (1NO+1NC, compatible with A/AF30 frames under new numbering)

This migration typically requires only minor wiring changes and preserves panel footprint, offering improved reliability, global availability, and compliance with current IEC standards. For facilities managing multiple legacy panels, a component-by-component refresh during maintenance windows provides a cost-effective transition strategy.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: