Description

Technical Specifications (For Spare Verification)

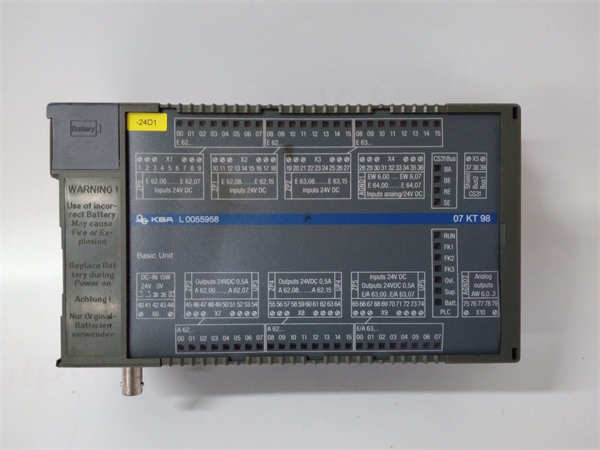

- Product Model: 07KT98

- Manufacturer: ABB

- ABB Order Code: GJR5253100R3160

- System Compatibility: AC 500 and AC 500-eCo PLC platforms

- Input Channels: 16 sink-type (NPN-compatible) digital inputs

- Rated Input Voltage: 24 VDC (operating range: 15–30 VDC)

- Input Current: ~3 mA at 24 VDC

- Input Filter Time: Adjustable via software (typically 0.2 ms to 20 ms)

- Isolation: 500 VAC between field and internal logic

- Diagnostic Features: Per-channel LED indication; group fault signaling via backplane

- Form Factor: Compact DIN-rail mount, single-slot width for AC 500 base units

- Power Consumption: ~1.2 W from internal 5 VDC bus

-

07KT98 GJR5253100R3160

System Role and Downtime Impact

The 07KT98 serves as a primary signal acquisition interface in ABB AC 500-based control systems, commonly found in packaging machinery, material handling conveyors, HVAC plants, and auxiliary process skids. It reads binary status from field devices—such as door switches, motor running feedback, or level sensors—and delivers this data to the CPU for logic execution. While not certified for high-integrity safety functions (e.g., SIL 3), it often supports safety-related permissive or interlock conditions in SIL 1 or basic machinery safety circuits. A complete module failure results in loss of up to 16 critical input signals, potentially causing the PLC to enter a safe state (e.g., halt sequence) or operate with degraded awareness—increasing risk of equipment damage or personnel exposure. Replacement requires physical installation, verification of wiring polarity (sink configuration), and functional testing within the application logic. Due to its obsolescence, mismatched firmware or hardware revisions may prevent proper recognition by the CPU, leading to extended troubleshooting.

Reliability Analysis and Common Failure Modes

Although solid-state and generally robust, the 07KT98 is susceptible to several age- and environment-driven failure mechanisms:

- Input optocoupler degradation: Prolonged exposure to voltage spikes or sustained overvoltage reduces the sensitivity of isolation components, leading to missed signal transitions—especially on channels with weak pull-up sources.

- Backplane connector corrosion: In humid or chemically aggressive environments, oxidation at the edge connector causes intermittent communication or partial channel dropout, often misdiagnosed as field wiring faults.

- Internal filter capacitor drift: Aging capacitors in the input filtering circuit alter response timing, causing erratic behavior under high electrical noise (e.g., near VFDs).

- LED indicator failure: While non-critical to function, failed status LEDs hinder troubleshooting during maintenance, increasing mean time to repair (MTTR).

A key limitation is the lack of per-channel diagnostic reporting to the CPU—only a general “module OK” signal is provided. Thus, a single failed input may go undetected unless actively monitored in the application logic.

Recommended preventive actions include:

- Implementing software debouncing and signal validation routines in the PLC program.

- Inspecting terminal blocks and backplane contacts during scheduled outages; cleaning with contact-safe solvent if contamination is present.

- Verifying input voltage levels at the module terminals under loaded conditions to ensure they meet minimum thresholds.

- Maintaining at least one verified spare with matching hardware revision (check label on module side).

-

07KT98 GJR5253100R3160

Lifecycle Status and Migration Strategy

ABB has formally discontinued the 07KT98 (GJR5253100R3160) as part of its product lifecycle management for early-generation AC 500 I/O modules. It is no longer listed in current catalogs, and official support is limited. New production has ceased, leaving only used or refurbished inventory—often without traceable service history. Continued reliance on this module introduces escalating risk of unplanned downtime and complicates compliance with modern asset management standards.

Short-term mitigation strategies include:

- Securing two tested and verified spares, preferably from the same original batch to ensure revision consistency.

- Engaging authorized ABB service partners for board-level inspection and component rework if needed.

- Documenting all wiring and addressing schemes to accelerate replacement during emergencies.

For long-term sustainability, migration to current-generation ABB I/O is advised. The direct functional replacement is the IO-D160 (order code: GJR5253100R4161), which offers:

- Identical 16-channel sink input functionality

- Enhanced noise immunity and wider operating temperature range

- Full compatibility with existing AC 500 and AC 500-eCo CPUs

- Continued manufacturer support and global availability

Migration requires only physical module swap and minor update in Automation Builder hardware configuration—no logic changes are needed. Facilities still using the 07KT98 should prioritize replacement during the next planned outage to eliminate obsolescence risk while maintaining system integrity and operational continuity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: