Description

Key Technical Specifications (For Spare Parts Verification)

- ABB Series: Likely part of the A or AF low-voltage contactor family (predecessor to modern ABB AFxx series)

- Poles: 3 main power poles + typically 1 NO (normally open) and 1 NC (normally closed) auxiliary contact

- Rated Operational Voltage (Ue): Commonly 230 VAC, 400 VAC, or 690 VAC (depends on coil variant)

- Insulation Voltage (Ui): 690 V

- Thermal Current (Ith): ~25–32 A (suggests ~7.5–11 kW motor at 400 V, 50 Hz)

- Coil Voltage: Often 230 VAC or 24 VDC (coil code must match application—check suffix if available)

- Mechanical Life: ~10 million operations

- Electrical Life: ~1 million operations (at rated load)

- Mounting: DIN rail or panel mount (35 mm standard DIN rail compatible)

- Standards Compliance: IEC 60947-4-1, CE marked

System Role and Downtime Impact

The ABB 0504994880 is a foundational component in motor control centers (MCCs), HVAC systems, pump panels, and conveyor drives. It enables programmable logic controllers (PLCs) or manual pushbuttons to safely energize high-power circuits. In safety-critical or continuous-process applications (e.g., cooling water pumps, compressor trains), contactor failure can lead to:

- Failure to start: Open coil or mechanical jam prevents operation → production stoppage

- Welded contacts: Contacts fuse shut due to arcing or overload → motor cannot be stopped → safety hazard or equipment damage

- Auxiliary contact failure: Disrupts feedback to control system → false status indication or interlock bypass

Unlike solid-state devices, electromechanical contactors provide galvanic isolation and fail-safe behavior when properly maintained—but they wear out with use.

Reliability Analysis and Common Failure Modes

Despite robust design, units in service for 15+ years are prone to:

- Contact erosion/welding: Caused by frequent switching of inductive loads (motors) without proper arc suppression

- Coil burnout: Due to voltage spikes, moisture ingress, or sustained overvoltage

- Spring fatigue: Leads to slow opening/closing, increasing arcing time

- Dust/oil contamination: Impairs moving parts and promotes tracking across terminals

- Loose terminal connections: Result in overheating and insulation degradation

Preventive maintenance recommendations:

- Perform visual inspection for pitting, discoloration, or carbon tracking

- Measure coil resistance to detect open/short windings

- Verify auxiliary contact continuity with multimeter during functional tests

- Tighten power and control terminals per torque specs during outages

- Replace proactively after 500,000+ operations or 10+ years in harsh environments

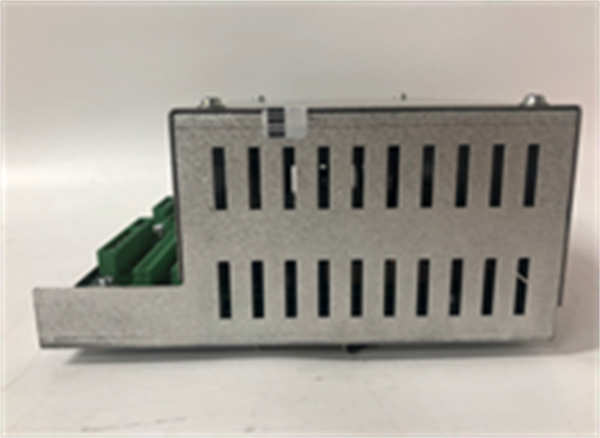

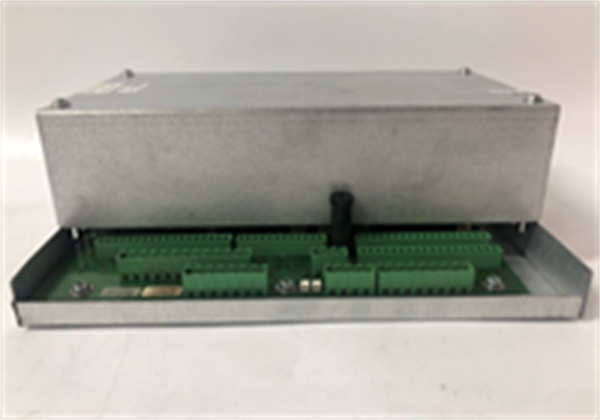

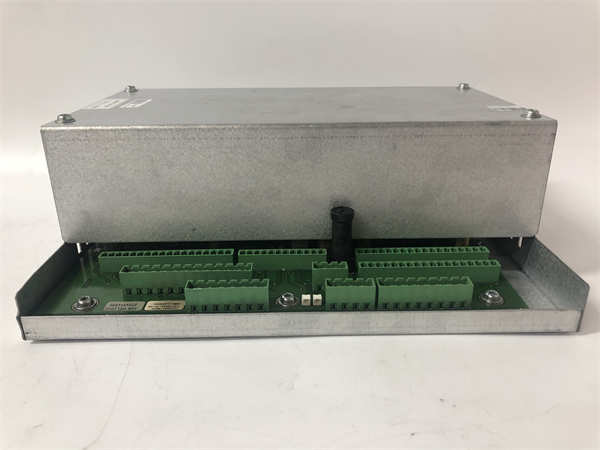

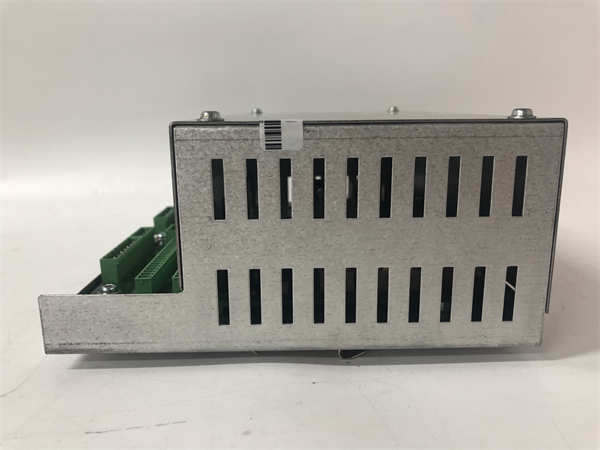

0504994880 ABB

Lifecycle Status and Migration Strategy

ABB has superseded older contactor families (like those using P/N 0504994880) with the AF series (e.g., AF30-30-11) featuring:

- Bidirectional coil compatibility (AC/DC)

- Integrated surge suppressors

- Improved arc chambers

- Global harmonization (replacing regional variants)

Direct replacement path:

- Cross-reference using ABB’s official obsolescence notice or product selector tools

- Most likely modern equivalent: ABB AF30-30-11 (30 A, 3 NO + 1 NO/1 NC aux, 230 VAC coil) — verify exact coil voltage and aux configuration

Migration considerations:

- Modern AF contactors are mechanically and electrically compatible with legacy DIN rail layouts

- Terminal spacing and mounting footprint are generally preserved

- Always confirm coil voltage matches control circuit (e.g., 24 VDC vs. 230 VAC)

- Update schematics and spare parts lists to reflect new part numbers

If immediate replacement isn’t feasible:

- Stock one or two verified-good spares from reputable surplus vendors

- Implement thermal imaging scans during operation to detect abnormal heating

- Consider adding external monitoring (e.g., contactor status sensors) to detect failure precursors

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: